Step-by-step lignocellulose saccharifying fermentation method with polyvinyl glycol-water as medium

A technology of lignocellulose and polyethylene glycol, applied in the directions of fermentation, microorganism-based methods, biochemical equipment and methods, etc., to achieve the effect of reducing energy consumption of ethanol distillation, reducing equipment investment, and reducing total cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

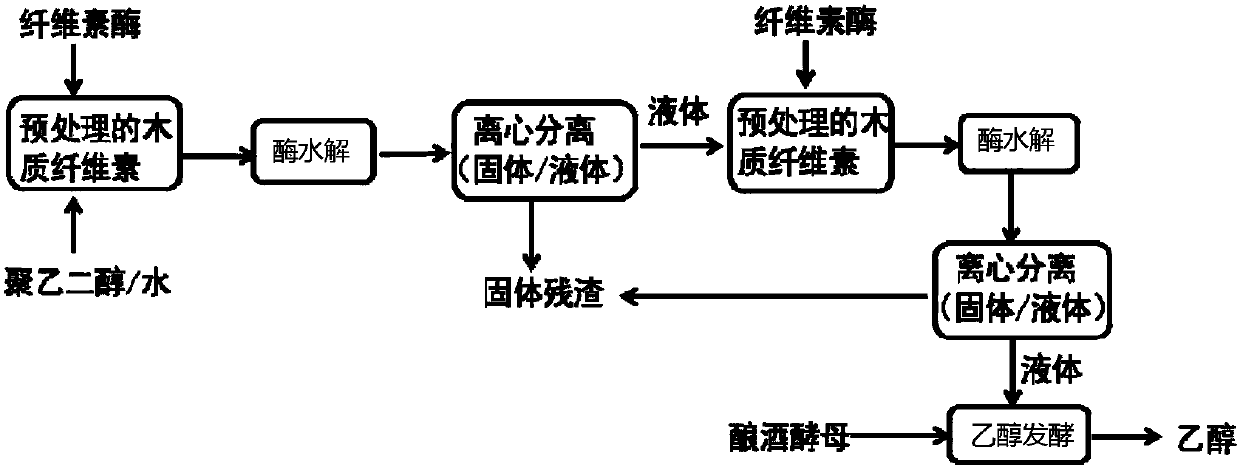

Method used

Image

Examples

Embodiment 1

[0025] The fast-growing poplar pretreated by the steam explosion method, polyethylene glycol (PEG-1000), and deionized water are mixed according to a solid-to-liquid ratio of 10%, and the mass ratio of polyethylene glycol to deionized water is 20%, and then cellulase 15FPU is added / g substrate, under the conditions of pH 4.85 and temperature 50°C, carry out preliminary enzymatic hydrolysis for 24 hours, and conduct solid-liquid separation of the obtained enzymatic hydrolysis slurry, and the glucose concentration in the obtained hydrolyzate is 40g / L; The solid-liquid ratio is 10%, and the fast-growing poplar and cellulase 15FPU / g substrate pretreated by steam explosion method are added to carry out enzymatic hydrolysis for 24 hours again, and the obtained enzymatic hydrolysis slurry is subjected to solid-liquid separation again, and the glucose concentration of the obtained hydrolyzate is 70g / L; Add Saccharomyces cerevisiae OD to the obtained hydrolyzate 600 The temperature i...

Embodiment 2

[0027] The fast-growing poplar pretreated by the steam explosion method, polyethylene glycol (PEG-200), and deionized water are mixed according to a solid-to-liquid ratio of 10%, and the mass ratio of polyethylene glycol to deionized water is 20%, and then cellulase 15FPU is added / g substrate, under the conditions of pH 4.85 and temperature 50°C, carry out preliminary enzymatic hydrolysis for 24 hours, and conduct solid-liquid separation of the obtained enzymatic hydrolysis slurry, and the glucose concentration in the obtained hydrolyzate is 41g / L; Solid-to-liquid ratio 10% added fast-growing poplar pretreated by steam explosion method, cellulase 15FPU / g substrate and carried out enzymatic hydrolysis again for 24 hours, and the enzymatic hydrolysis slurry obtained was subjected to solid-liquid separation again, and the glucose concentration of the obtained hydrolyzate was 72g / L; Saccharomyces cerevisiae OD was added to the obtained hydrolyzate 600 The temperature is 2.0, and ...

Embodiment 3

[0029] The straw pretreated by steam explosion method, polyethylene glycol (PEG-2000), and deionized water are mixed according to the solid-to-liquid ratio of 10%, the mass ratio of polyethylene glycol to deionized water is 20%, and then cellulase 15FPU / g substrate, under the conditions of pH 4.85 and temperature 50°C, carry out preliminary enzymatic hydrolysis for 24 hours, and carry out solid-liquid separation of the obtained enzymatic hydrolysis slurry, and the glucose concentration in the obtained hydrolyzate is 45g / L; The liquid ratio is 10%, and the fast-growing poplar and cellulase 15FPU / g substrate pretreated by steam explosion method are added to carry out enzymatic hydrolysis for 24 hours again, and the obtained enzymatic hydrolysis slurry is subjected to solid-liquid separation again, and the glucose concentration of the obtained hydrolyzate is 86g / L; Add Saccharomyces cerevisiae OD to the obtained hydrolyzate 600 The temperature is 2.0, and the temperature is 33°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com