Black wrapping film and preparation method thereof

A stretch film and black technology, which is applied in the field of black stretch film and its preparation, can solve the problems of large amount of tackifier masterbatch, short delivery cycle, and increased cost, and achieve low production equipment requirements, good control, and lighten the environment. The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

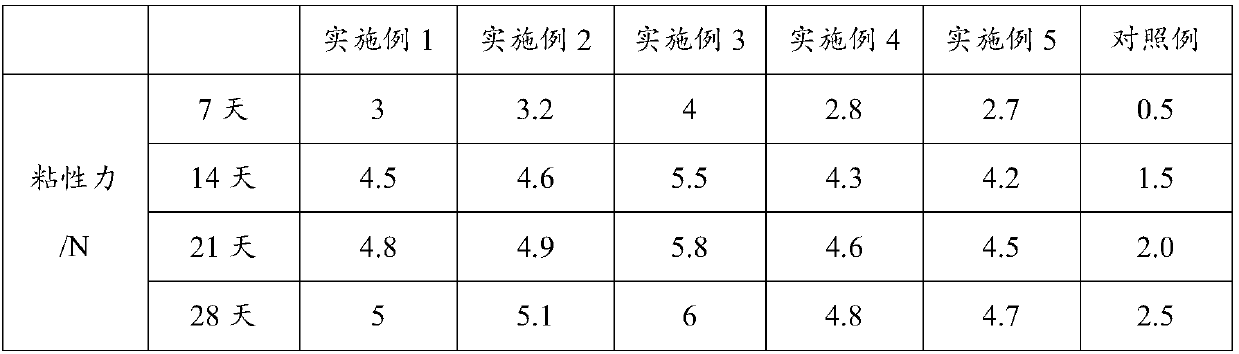

Examples

Embodiment 1

[0022] A black stretch film, the raw materials of which are calculated by mass percentage: 82% of linear low-density polyethylene, 2% of black masterbatch, 6% of tackifying masterbatch, and 10% of recycled material;

[0023] Wherein said black masterbatch is calculated by mass percentage, comprises: carrier polyethylene 43%, carbon black 44%, dispersant is the polyethylene wax 13% of number-average relative molecular weight 2000, and does not contain the smooth agent of soap salt or opening agent;

[0024] Wherein, the tackifying masterbatch includes: 55% of polyethylene and 45% of polyisobutylene in terms of mass percentage.

[0025] Wherein the recycled material is leftover material generated during the stretch film preparation process.

[0026] The preparation method of above-mentioned black stretch film, comprises:

[0027] 1) Put the linear low-density polyethylene, black masterbatch, thickening masterbatch and recycled material into the mixer in proportion, stir and mi...

Embodiment 2

[0030] A black stretch film, the raw materials of which are calculated by mass percentage: 61% of linear low density polyethylene, 20% of metallocene linear low density polyethylene, 3% of black masterbatch, 6% of tackifying masterbatch, and 10% of recycled material ;

[0031] Wherein said black masterbatch is calculated by mass percentage, comprises: carrier polyethylene 50%, carbon black 30%, dispersant is the polyethylene wax 20% of number-average relative molecular weight 3000, and does not contain the smooth agent of soap salt or opening agent;

[0032] Wherein, the tackifying masterbatch includes: 45% polyethylene and 55% polyisobutylene in terms of mass percentage.

[0033] Wherein the recycled material is leftover material generated during the stretch film preparation process.

[0034] The preparation method of above-mentioned black stretch film, comprises:

[0035] 1) Put linear low-density polyethylene, metallocene linear low-density polyethylene, black masterbatc...

Embodiment 3

[0038] A black stretch film, the raw materials of which are calculated by mass percentage, including: 83% of linear low-density polyethylene, 8% of black masterbatch, and 9% of tackifying masterbatch;

[0039] Wherein the black masterbatch is calculated by mass percentage, comprising: 50% of carrier polyethylene, 25% of carbon black, 25% of polyethylene wax with a number-average molecular weight of 3500 as a dispersant, and does not contain soap salts such as zinc stearate , calcium stearate and other slip agents or anti-blocking agents;

[0040] Wherein, the tackifying masterbatch includes: 65% of polyethylene and 35% of polyisobutylene in terms of mass percentage.

[0041] Wherein the recycled material is leftover material generated during the stretch film preparation process.

[0042] The preparation method of above-mentioned black stretch film, comprises:

[0043] 1) Put the linear low density polyethylene, black masterbatch and tackifier masterbatch into the mixer in pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com