Novel floor heating material and preparation process thereof

A heat-generating material and preparation technology, applied in architecture, building structure, floor, etc., can solve the problems of complex design, large power consumption, and high cost, and achieve the effect of simple design, low power consumption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

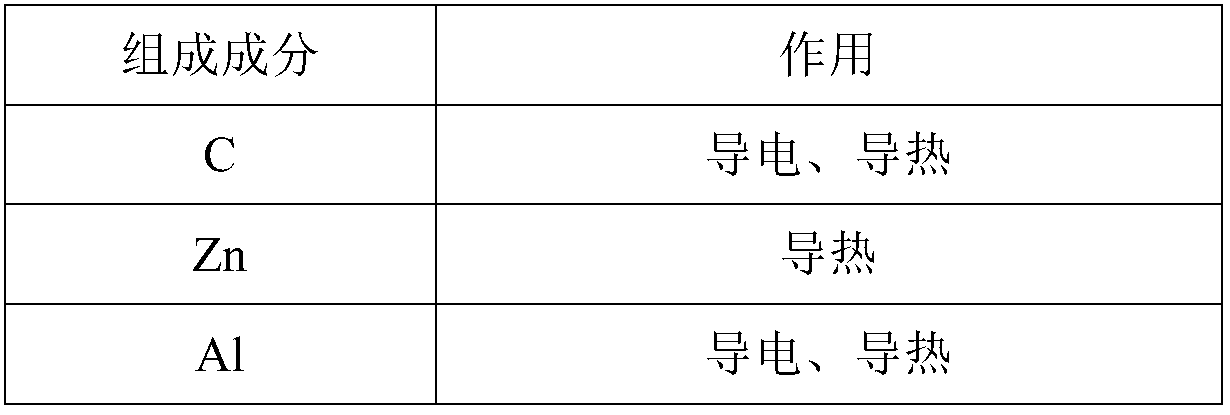

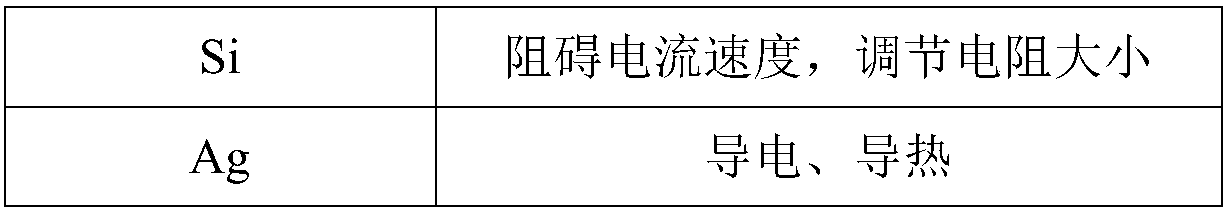

[0026] A new type of floor heating material, the new type of floor heating material is prepared from a heating dry powder and a binder; wherein, the mass ratio of the heating dry powder to the binder is 7:3; expressed in mass percentage, the heating The composition of the dry powder is: 88.15% of C, 4.10% of Zn, 5.25% of Al, 2.25% of Si and 0.25% of Ag; the binder is silica sol.

[0027] The preparation process of the above-mentioned novel floor heating material specifically includes the following steps:

[0028] (1) Weigh each raw material according to the composition of the above-mentioned exothermic dry powder, then add each raw material in the mixer, stir and mix evenly, and obtain the exothermic dry powder;

[0029] (2) Add the binder into the kneader, then slowly add the heat-generating dry powder into the kneader, and stir while adding. After the heat-generating dry powder and the binder are mixed evenly, stop stirring and let stand for 4 hours; after standing , contin...

Embodiment 2

[0034] A new type of floor heating material, the new type of floor heating material is prepared from a heating dry powder and a binder, wherein the mass ratio of the heating dry powder to the binder is 5:1; expressed in mass percentage, the heating The composition of the dry powder is: 87.7% of C, 3.5% of Zn, 6.0% of Al, 2.5% of Si and 0.3% of Ag; the binder is aluminum sol.

[0035] The preparation process of the above-mentioned novel floor heating material specifically includes the following steps:

[0036] (1) Weigh each raw material according to the composition of the above-mentioned exothermic dry powder, then add each raw material in the mixer, stir and mix evenly, and obtain the exothermic dry powder;

[0037] (2) Add the binder into the kneader, then slowly add the heat-generating dry powder into the kneader, and stir while adding. After the heat-generating dry powder and the binder are mixed evenly, stop stirring and let stand for 6 hours; after standing , continue t...

Embodiment 3

[0042] A new type of floor heating material, the new type of floor heating material is prepared from a heating dry powder and a binder, wherein the mass ratio of the heating dry powder to the binder is 9:5; expressed in mass percentage, the heating The composition of the dry powder is: 85.6% of C, 5.0% of Zn, 6.0% of Al, 3.0% of Si and 0.4% of Ag; the binder is aluminum sol.

[0043] The preparation process of the above-mentioned novel floor heating material specifically includes the following steps:

[0044] (1) Weigh each raw material according to the composition of the above-mentioned exothermic dry powder, then add each raw material in the mixer, stir and mix evenly, and obtain the exothermic dry powder;

[0045] (2) Add the binder into the kneader, then slowly add the heat-generating dry powder into the kneader, and stir while adding. After the heat-generating dry powder and the binder are evenly mixed, stop stirring and let stand for 2 hours; after standing , continue t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com