Multi-action sequence mechanism reliability assessment method

A technology of action sequence and reliability, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as error in analysis results, and achieve the effect of feasible method and strong practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

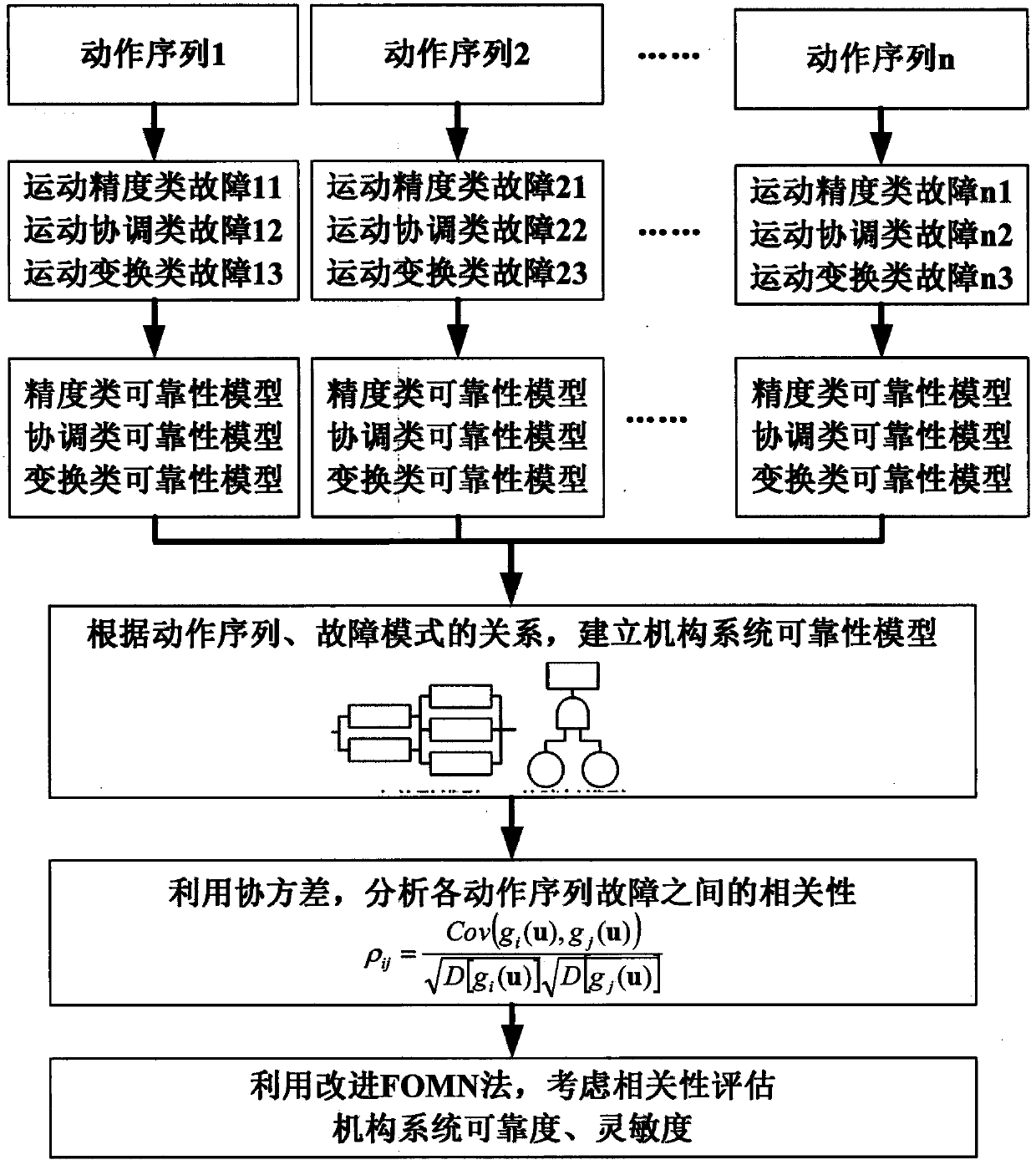

[0014] The flow chart of the present invention is as figure 1 shown, including the following steps:

[0015] 1 Analyze the action sequence of the mechanism, and for each action sequence in turn, analyze the failure modes related to the motion function, including the occurred and potential failures.

[0016] Firstly, the kinematics analysis of the mechanism is carried out, and the movement of the mechanism is disassembled into multiple action sequences. For example, the artillery ammunition loading mechanism includes action series such as feeding, closing the bolt, locking, firing, unlocking, unbolting, extracting the shell, and ejecting the shell. Using the fault data of the mechanism, the fault data of similar mechanisms, etc., the basic fault modes related to the main movement of each action sequence of the mechanism are analyzed according to the following aspects:

[0017] 1) Motion accuracy faults, such as displacement, speed, acceleration out of tolerance, excessive moti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com