Inverted cold-bent U-shaped steel composite beam bridge connected through lacing bars and construction method

A U-shaped steel, inverted technology, used in bridges, bridge parts, bridge construction and other directions, can solve the problems of low overall stiffness and torsion resistance of bridges, poor lateral stability of bridge structures, endangering traffic and pedestrian safety, etc. Small hoisting capacity, reduced anti-corrosion workload and less fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical scheme of the present invention will be described in further detail below with reference to the accompanying drawings.

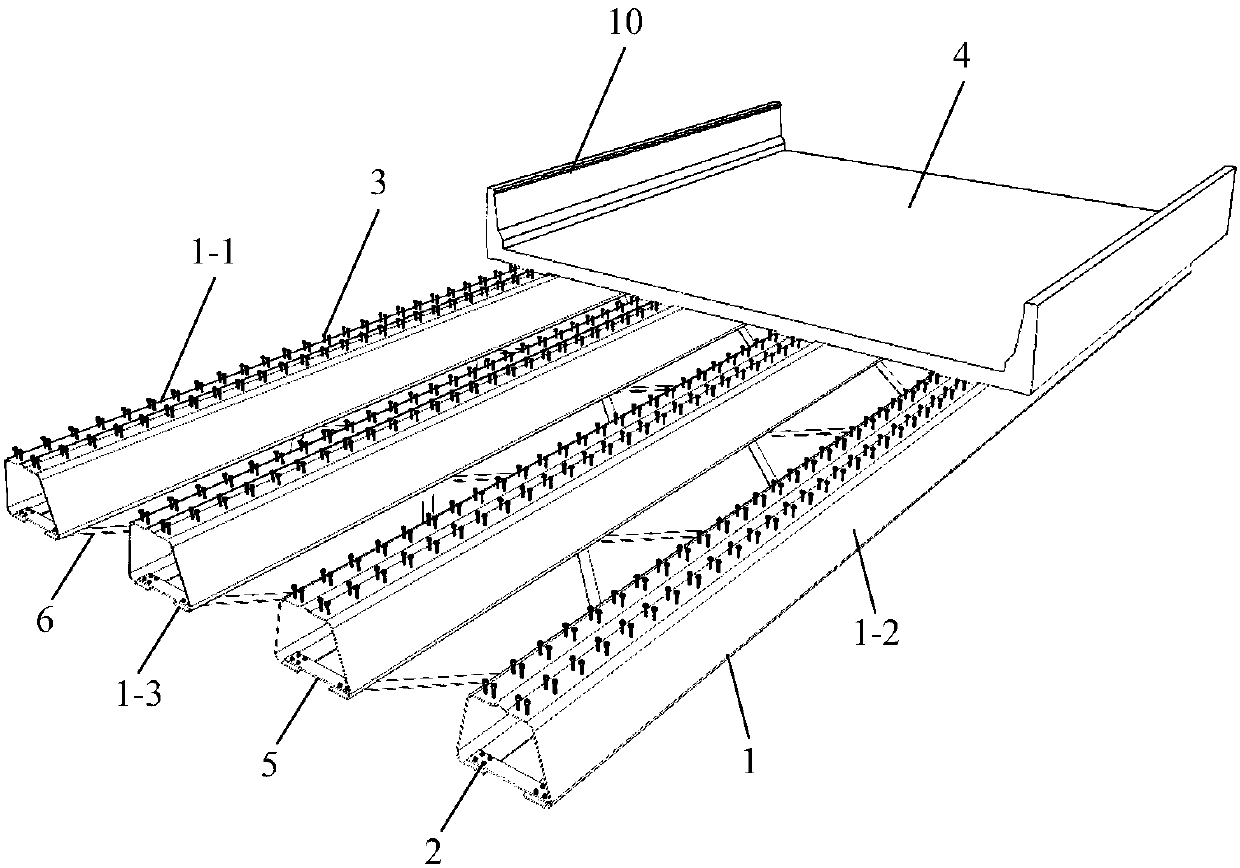

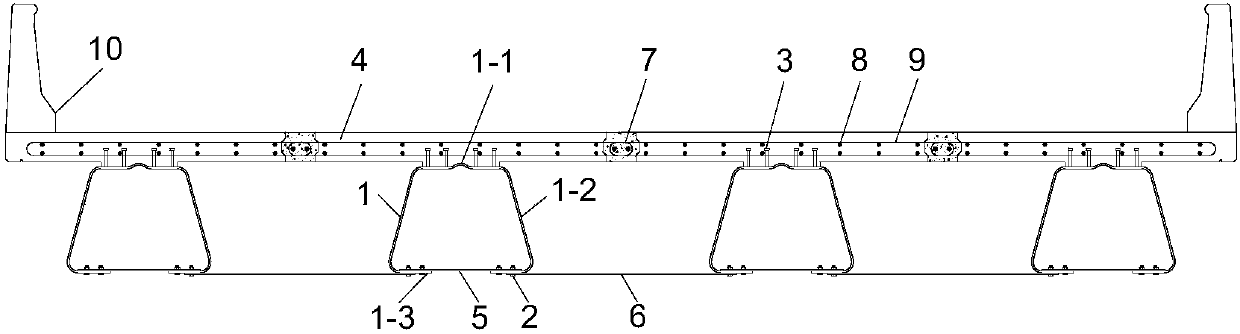

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the present invention includes: some cold-formed U-shaped steel girders 1 and prefabricated concrete bridge decks 4 arranged in parallel, some shear nails 3 are welded on the top surface of some cold-formed U-shaped steel beams 1, and some shear nails 3 A precast concrete bridge deck 4 is arranged on it, that is, the precast concrete bridge deck 4 is set on the cold-formed U-shaped steel girder 1 through shear nails 3 .

[0042] Each cold-formed U-shaped steel beam 1 includes an upper flange plate 1-1 and a lower flange plate 1-3, and a web 1-2 is arranged between the upper flange plate 1-1 and the lower flange plate 1-3 , the upper flange plate 1-1, the lower flange plate 1-3 and the web 1-2 form a trapezoidal s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com