Anti-electromagnetic radiation fabric and manufacturing process thereof

A technology of anti-electromagnetic radiation and preparation technology, which is applied to special surfaces, devices for coating liquid on surfaces, fabrics, etc., can solve the problems of affecting the shielding effect of products, affecting the service life of products, and unsatisfactory shielding effects, and achieves the goal of weaving. Novelty, multiple functions, excellent skin-friendly antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

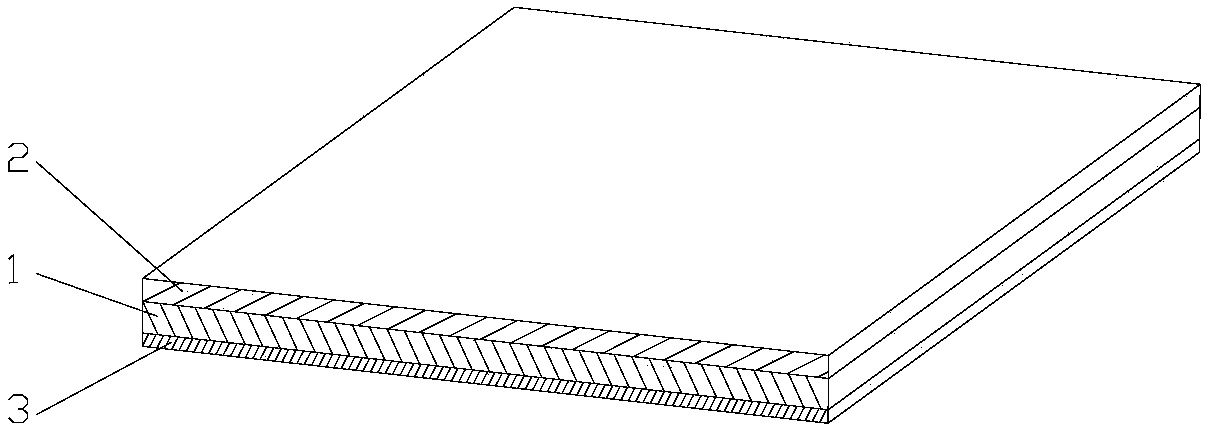

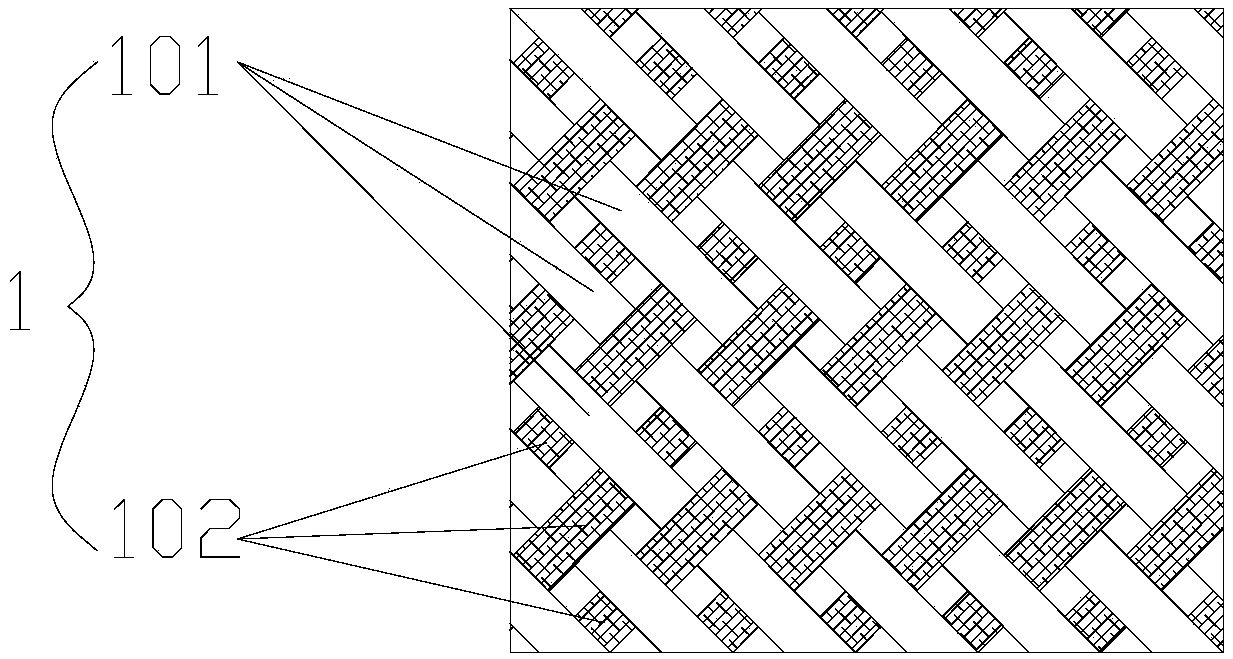

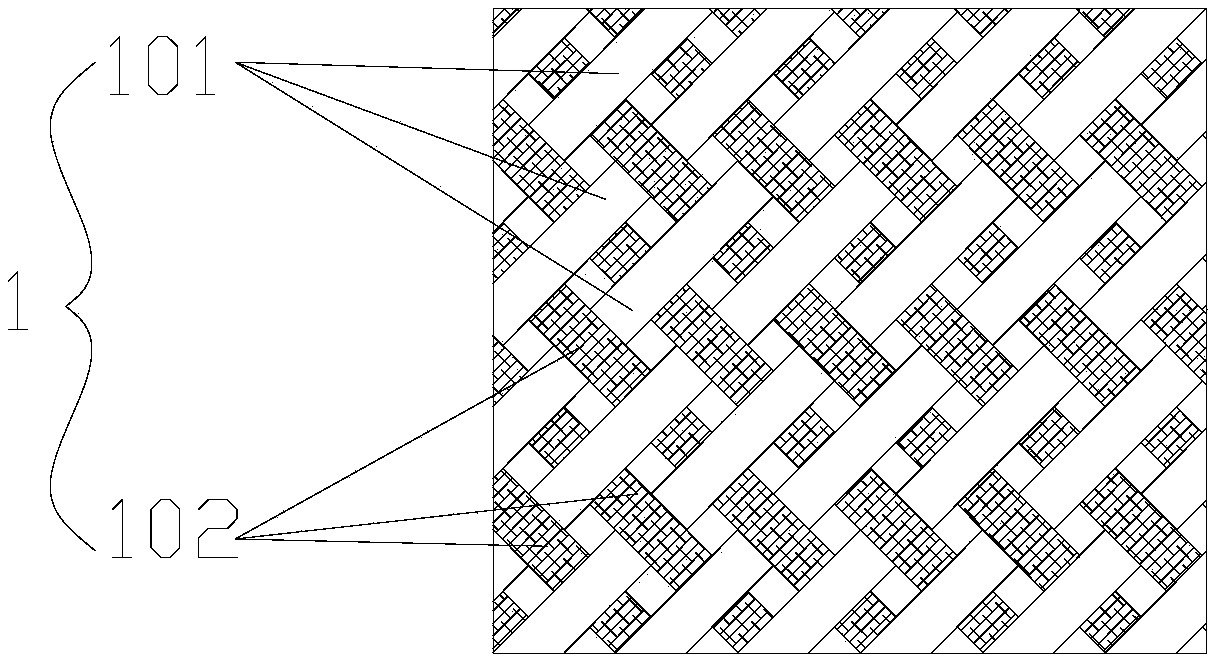

[0038] Embodiment 1 of the present invention: as Figure 1-Figure 3 As shown, an anti-electromagnetic radiation fabric includes a radiation-proof shielding layer 1, and the radiation-proof shielding layer 1 is woven from warp threads 101 and weft threads 102, wherein at least one of the warp threads 101 and the weft threads 102 is made of magnesium or a magnesium alloy production. Magnesium and magnesium alloy materials have low density and have good electromagnetic shielding performance. Specifically, the principle of electromagnetic shielding is to use the reflection of electromagnetic waves on the surface of magnesium or magnesium alloys and the sharp attenuation of propagation in magnesium or magnesium alloys to isolate time-varying electromagnetic fields. Mutual coupling, thus preventing the interference of low-frequency and high-frequency electromagnetic fields. The anti-electromagnetic radiation fabric made of magnesium or magnesium alloy has excellent electromagnetic ...

Embodiment 2

[0039] Embodiment 2: as figure 1 and figure 2 As shown, an anti-electromagnetic radiation fabric includes a radiation-proof shielding layer 1, and the radiation-proof shielding layer 1 is woven from warp threads 101 and weft threads 102, wherein at least one of the warp threads 101 and the weft threads 102 is made of magnesium or a magnesium alloy production. Magnesium and magnesium alloy materials have low density and have good electromagnetic shielding performance. Specifically, the electromagnetic shielding performance is to isolate time-varying electromagnetic fields by using the reflection of electromagnetic waves on the surface of magnesium or magnesium alloys and the sharp attenuation of propagation in magnesium or magnesium alloys. Mutual coupling, thus preventing the interference of low-frequency and high-frequency electromagnetic fields. The conductivity of magnesium or magnesium alloy is 2.3×10 7s / m, the relative permeability is 1. Compared with metals Ag and C...

Embodiment 3

[0040] Embodiment 3: as figure 1 and figure 2 As shown, an anti-electromagnetic radiation fabric includes a radiation-proof shielding layer 1, and the radiation-proof shielding layer 1 is woven from warp threads 101 and weft threads 102, wherein at least one of the warp threads 101 and the weft threads 102 is made of magnesium or a magnesium alloy production. Magnesium and magnesium alloy materials have low density and have good electromagnetic shielding performance. Specifically, the principle of electromagnetic shielding is to use the reflection of electromagnetic waves on the surface of magnesium or magnesium alloys and the sharp attenuation of propagation in magnesium or magnesium alloys to isolate time-varying electromagnetic fields. Mutual coupling, thus preventing the interference of low-frequency and high-frequency electromagnetic fields. The anti-electromagnetic radiation fabric made of magnesium or magnesium alloy has excellent electromagnetic shielding performanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com