Electrostatic spinning submicron fiber and sliver composite blended yarn preparation device and method

A preparation device and sub-micron technology, which is applied in fiber processing, textiles, papermaking, yarn, etc., can solve the problems of spinning liquid dripping onto the yarn or machine, high cost of carding machine transformation, and sub-micron fiber shedding, etc., to achieve The effect of many available varieties, convenient equipment transformation, and simple equipment transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

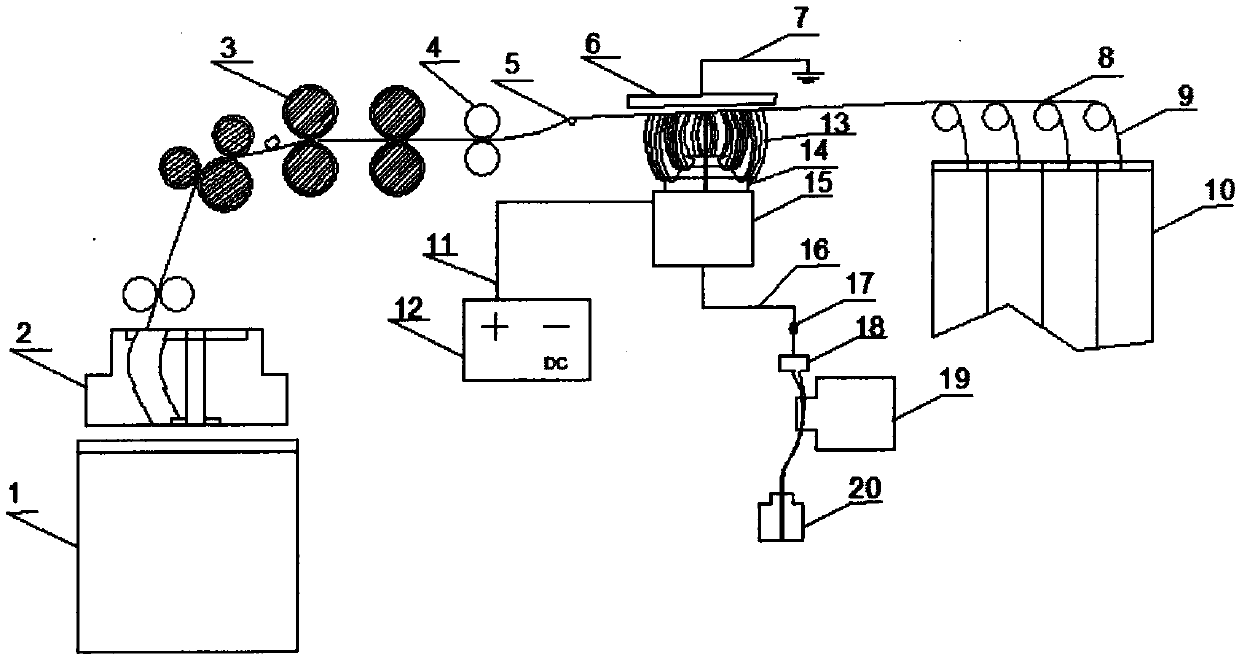

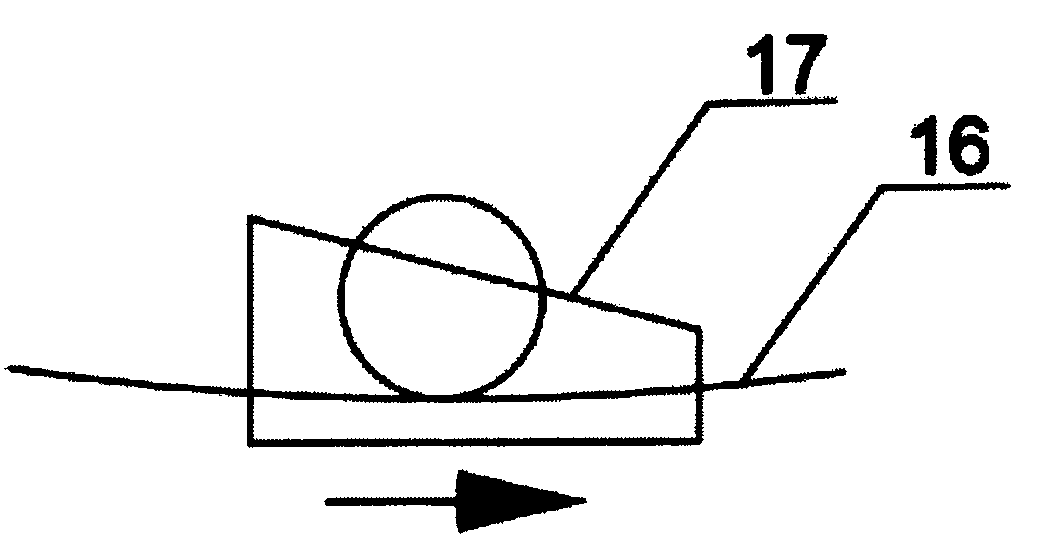

[0027] like figure 1 As shown, the preparation device for a kind of electrospinning submicron fiber / cotton sliver composite blended yarn provided by the present invention includes a draw frame, and the draw frame includes a feeding barrel 10, and a sliver 9 fed into the barrel 10 After successively passing through guide roller 8, guide rod 5, feeding roller 4 and drafting roller 3, the coiler 2 falls into barrel 1, and it is characterized in that, between the guide roller 8 and guide rod 5 An electrospinning device is arranged between them, and the electrospinning device includes a needle-free electrospinning nozzle 14 and a receiving pole plate 6 respectively located on both sides of the sliver 9, and the receiving pole plate is installed directly above the sliver, with a distance of 5 -20mm, not only to avoid the contact between the receiving plate and the sliver, but also to ensure the normal progress of electrospinning. The receiving electrode plate 6 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com