Pyrolysis furnace with wear-resistant radiation pipes

A pyrolysis furnace and radiant tube technology, applied in the field of pyrolysis furnaces, can solve the problems of weakening wear, affecting the normal operation of the device, wear and other problems, and achieve the effects of prolonging the service life, ensuring safe and normal operation, and extending the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

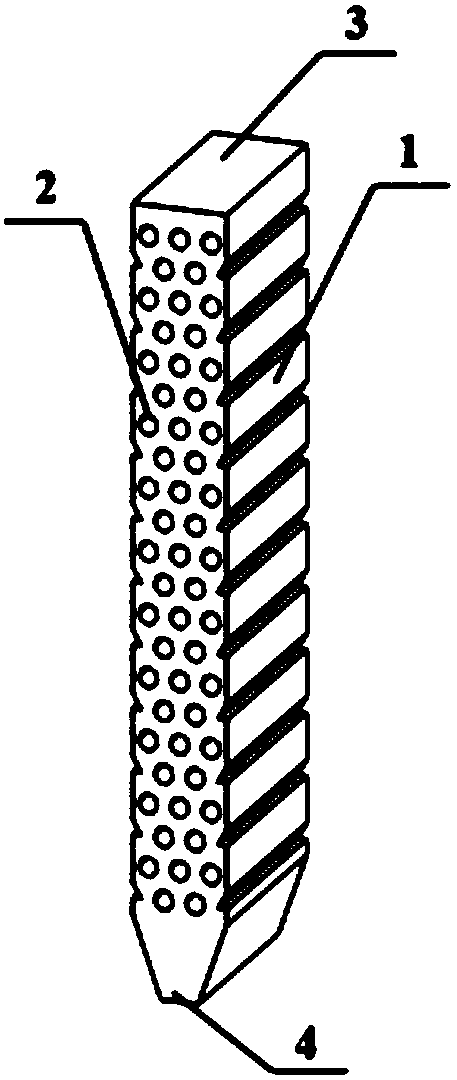

[0035]The triangular tube cap is welded on the radiant tube through a rectangular sheet, and the radiant tube is arranged in a vertical square pyrolysis furnace, so that the horizontal and vertical distances between two radiant tubes are the same. in:

[0036] The height of the vertical square regenerative fast pyrolysis furnace is 12 m, the top is a rectangle of 1.4*3.0 m, the bottom is a rectangle of 0.5*3 m, and 55 radiant tubes are arranged inside, and a total of 22 layers are arranged;

[0037] The diameter of the radiant tubes in the vertical square regenerative fast pyrolysis furnace is 200 mm, and the horizontal and vertical distances between two radiant tubes are 410 mm respectively;

[0038] The particle size distribution of pulverized coal particles in the vertical square heat storage pyrolysis furnace is relatively wide, the particle size range is concentrated between 0.18 and 3 mm, and about 50% of the particle size is between 1 and 2 mm;

[0039] The vertical di...

Embodiment 2

[0042] The triangular tube cap is welded on the radiant tube through a rectangular sheet, and the radiant tube is arranged in a vertical square pyrolysis furnace, so that the horizontal and vertical distances between two radiant tubes are the same. in:

[0043] The vertical cylindrical regenerative fast pyrolysis furnace has a height of 30 m and a diameter of 30 m, and 100 radiant tubes are arranged inside, and a total of 10 layers are arranged;

[0044] The diameter of the radiant tubes in the vertical cylindrical regenerative fast pyrolysis furnace is 200 mm, and the horizontal and vertical distances between two radiant tubes are 410 mm respectively;

[0045] The particle size distribution of pulverized coal particles in the vertical cylindrical regenerative pyrolysis furnace is relatively wide, and the particle size range is concentrated between 0.18 and 3 mm, and about 50% of the particles have a particle size between 1 and 2 mm;

[0046] The vertical distance from the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com