Spiral push type biomass continuous thermal pyrolysis multi-stage reaction device and method

A multi-stage reaction and helical propulsion technology, which is applied in special forms of dry distillation, gas purification of condensed non-gaseous materials, petroleum industry, etc., can solve the problems of energy loss, lower reactor temperature, high manufacturing cost, etc., and achieve simple design and easy removal Coke, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

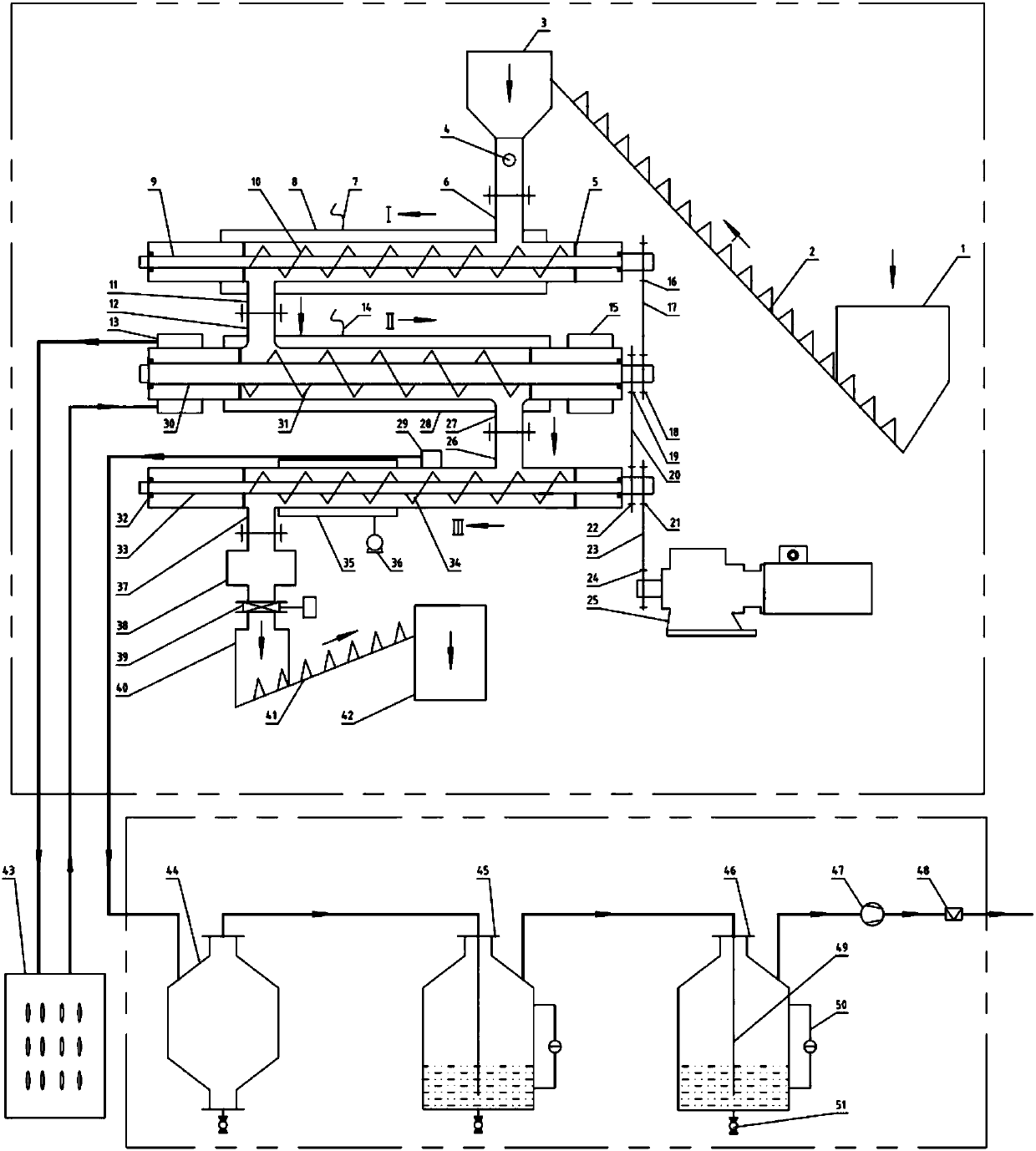

[0034] Attached to the invention figure 1 The shown spiral propulsion type biomass continuous pyrolysis multi-stage reaction device includes a first-stage reactor, a second-stage reactor and a third-stage reactor vertically arranged from top to bottom; the first-stage reactor, the second-stage The reactor and the third-stage reactor are connected in series from end to end, specifically: a crawler conveyor I2 is also arranged upstream of the first-stage reactor; an exhaust hole 4 is provided at the outlet pipe wall of the crawler conveyor I2 . The top at one end of the primary reactor is provided with a feed port 6, and the feed port 6 communicates with the outlet of the crawler conveyor 12; the bottom of the other end of the primary reactor is provided with a primary outlet 11;

[0035] The feed port 6 is connected to the fully enclosed crawler conveyor I2, and the material is transported by the crawler conveyor I2 and falls into the primary reactor through the feed port 6. ...

Embodiment 2

[0048] The method for using the device described in the above-mentioned embodiment 1 is as follows:

[0049] Using rice husks with a water content of 11% as raw materials, the device disclosed by the invention is used for continuous thermal cracking of rice husks to produce biochar, bio-oil, wood vinegar and clean gas. The rice husk is transported to the entrance of the primary reactor (I) by a conveyor belt, and falls freely into the primary reactor by gravity. The temperature in the heating zone of the primary reactor is maintained at 150°C ± 10°C, and the material runs inside the reactor ( The preheating) time is 6 minutes, and the running time is controlled by the control motor. After preheating, the material enters the secondary reactor (II) through the secondary feed port 11, and the temperature in the heating zone of the secondary reactor is maintained at 500 ° C ± 10 ℃, the material running (thermal cracking) time is 6 minutes, the cracked product enters the interior o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com