Damping assembly for preventing damage of film membrane and filtering membrane assembly utilizing damping assembly

A film and component technology, applied in ultrafiltration, membrane technology, semi-permeable membrane separation, etc., can solve problems such as large stress, damage to the strength and quality of the film, to improve the strength and quality, facilitate the smooth filtration of water, and increase contact face effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

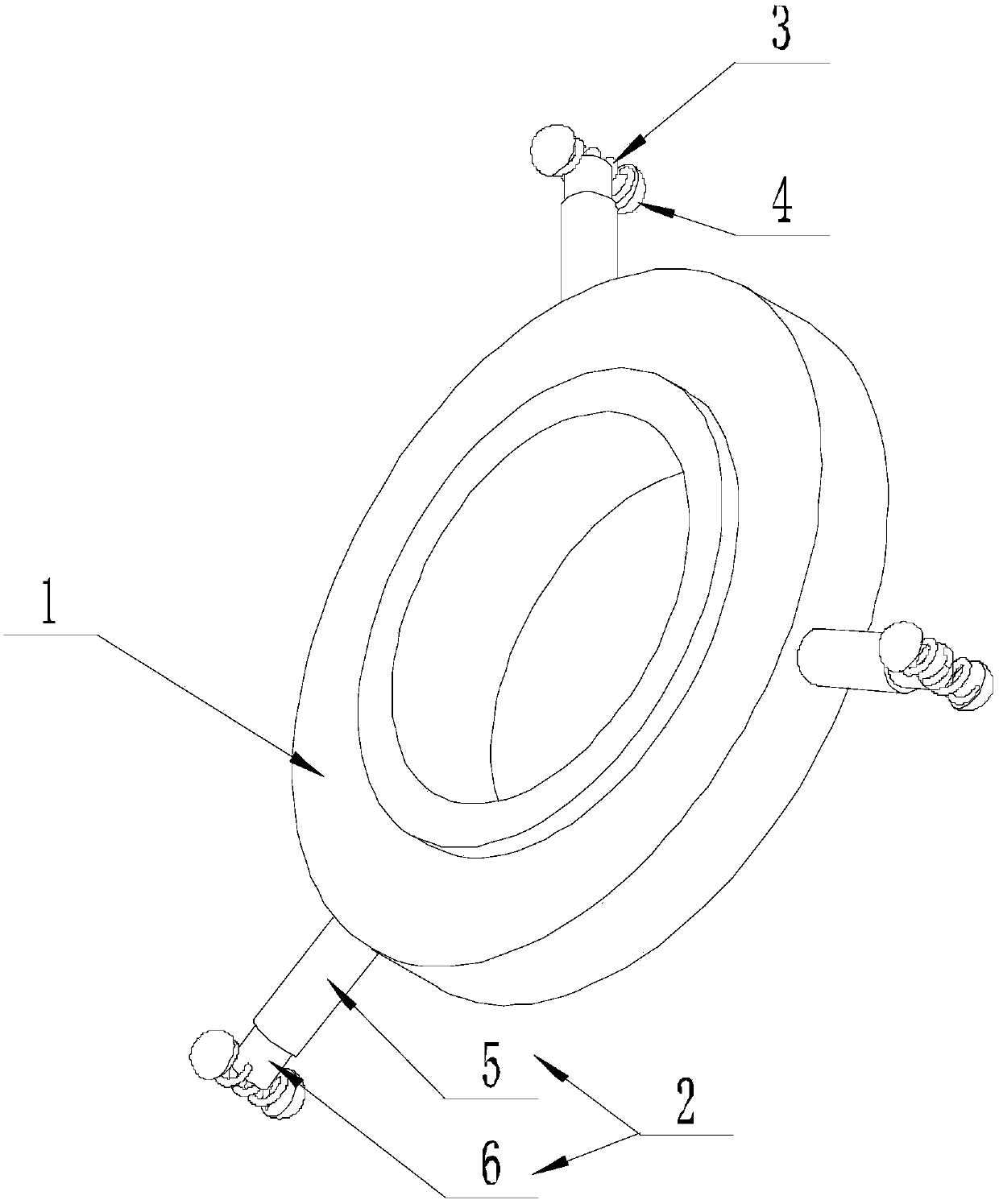

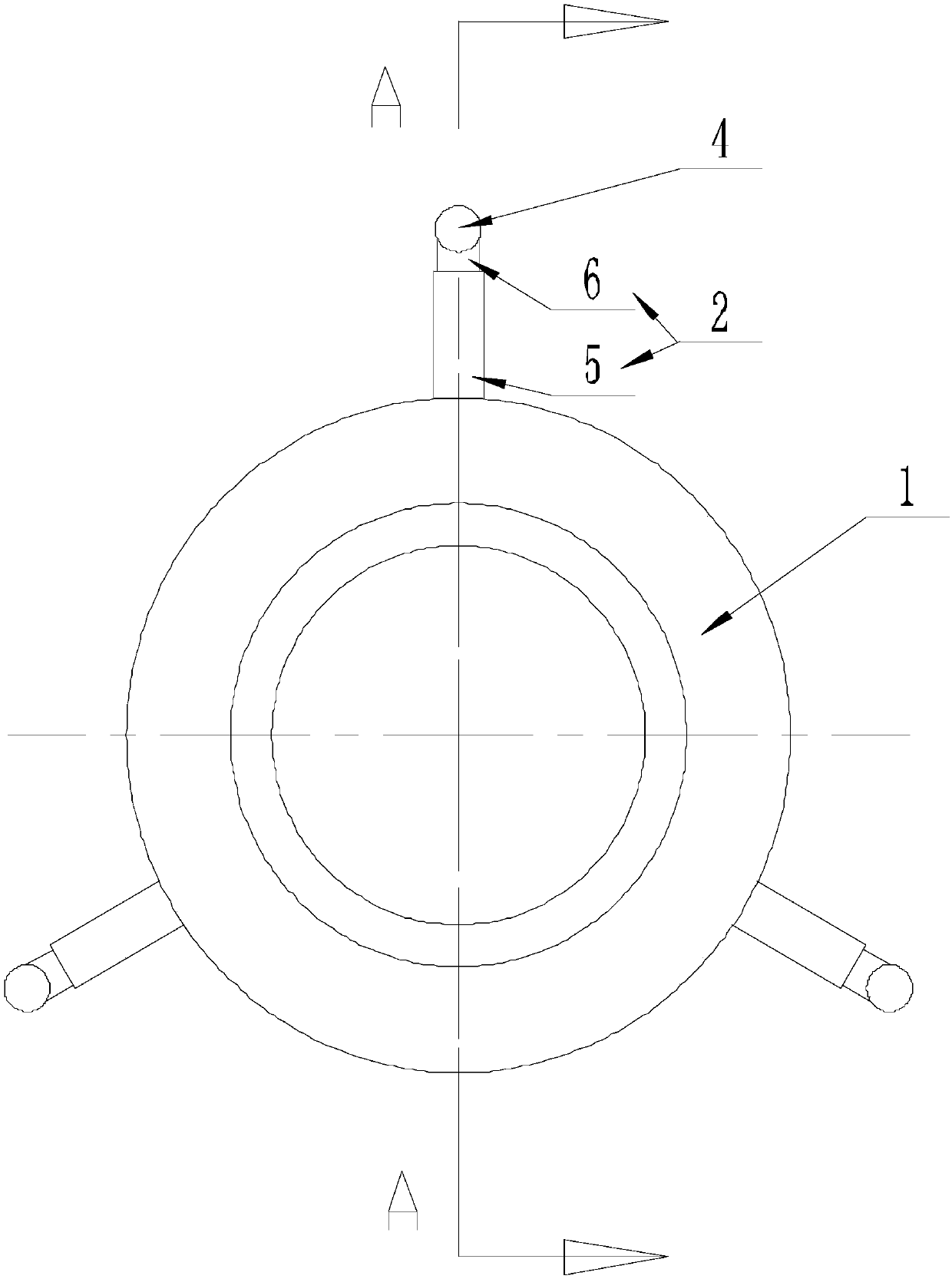

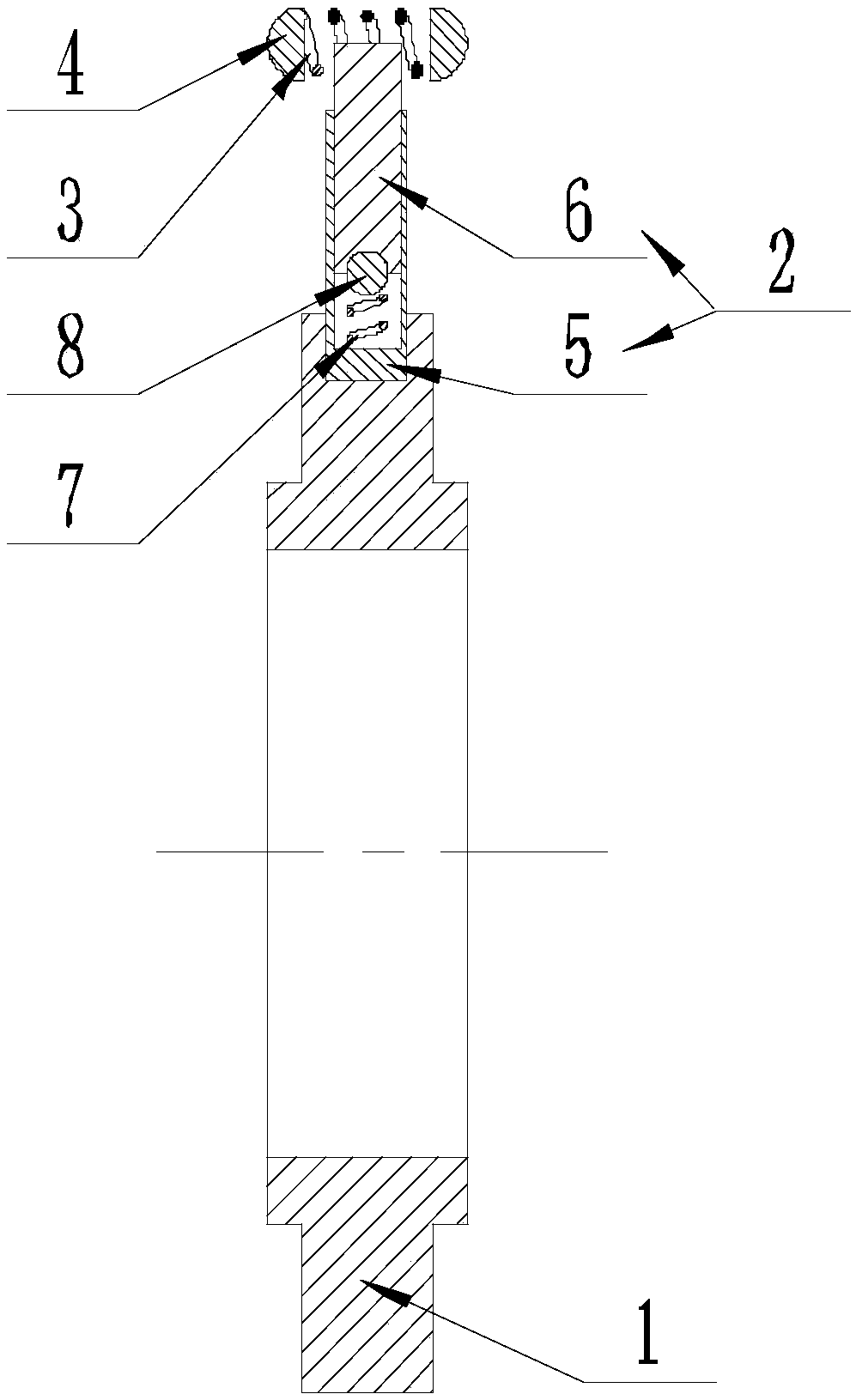

[0051] Such as Figure 1-Figure 7 As shown, the shock absorbing assembly for preventing damage to the film of the present invention includes a positioning ring 1, a shock absorbing assembly is arranged on the side wall of the positioning ring 1, and the shock absorbing assembly includes a telescopic rod 2 connected in sequence and an elastic Assembly, one end of the telescopic rod 2 is connected to the outer wall of the positioning ring 1, and the other end of the telescopic rod 2 is connected to the elastic component, and the telescopic direction of the elastic component is parallel to the axis of the positioning ring 1.

[0052] On the permeable pipe, the two adjacent positioning rings 1 fix and clamp the film between them, so the positioning ring 1 is located between the two adjacent film films, and at the same time, the elastic component is far away from the lifting rod 2 One end of each is in contact with a soft film, such as Figure 7 shown.

[0053] When the film shak...

Embodiment 2

[0055] This embodiment is based on Embodiment 1, and further explains the elastic component.

[0056] Such as Figure 1-Figure 7 As shown, the present invention prevents the damping assembly of the film from being damaged. The elastic assembly includes a damping spring 3. Contact blocks 4 are arranged at both ends of the damping spring (3). The damping spring 3 The axis of the shaft is parallel to the axis of the positioning ring 1, its side wall is connected with the end of the telescopic rod 2 away from the positioning ring 1, and its other end is connected with the contact block 4.

[0057] When the film swings towards the positioning ring 1, the end of the side wall of the film film close to the positioning ring 1 contacts the contact block 4, and compresses the damping spring 3, and then buffers by compressing the shock absorbing spring 3 to reduce the position on the film film. The stress on the part where the ring is clamped.

[0058] Due to the setting of the shock-a...

Embodiment 3

[0063] This embodiment is based on the first embodiment, and further explains the telescopic rod 2 .

[0064] Such as Figure 1-Figure 7 As shown, the present invention prevents the damping assembly of the film film from being damaged. The telescopic rod 2 includes a fixed cylinder 5 and a screw rod 6 that are sequentially connected and coaxial. The bottom of the fixed cylinder 5 is connected with the positioning ring 1. One end of the screw rod 6 is inserted into the central hole of the fixing cylinder 5 and threadedly connected with the central hole of the fixing cylinder 5, and the other end of the screw rod 6 is connected with the elastic component.

[0065] The setting of the telescopic rod is convenient for adjusting the contact position of the film film and the shock absorbing assembly according to needs. The adjustment of the axial length of the telescopic rod can be completed by rotating the screw rod 6 .

[0066] Further, a force spring 7 is arranged in the central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com