Anti-shake moving cutting machine for self-heat-preservation building block assembly line

A self-insulating block and cutting machine technology, which is applied to ceramic molding machines and manufacturing tools, can solve the problems of operator injury, low production efficiency, and high cost, and achieve smooth and smooth cutting, increased production efficiency, and reduced vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

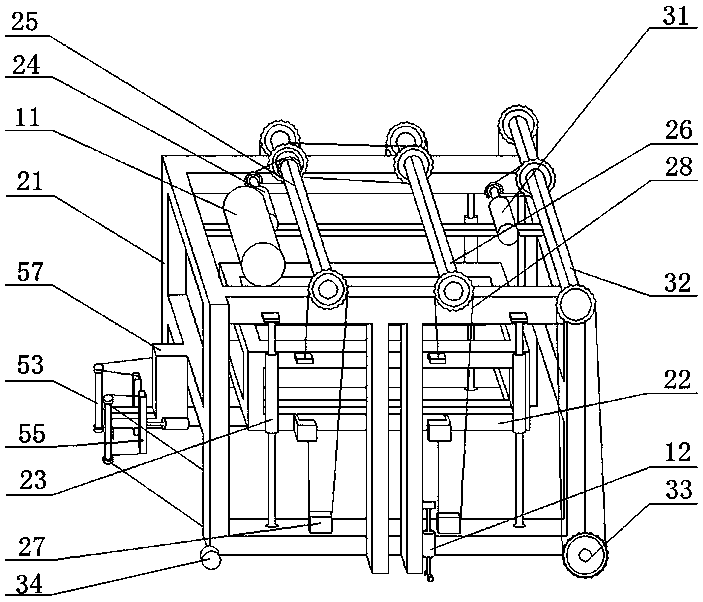

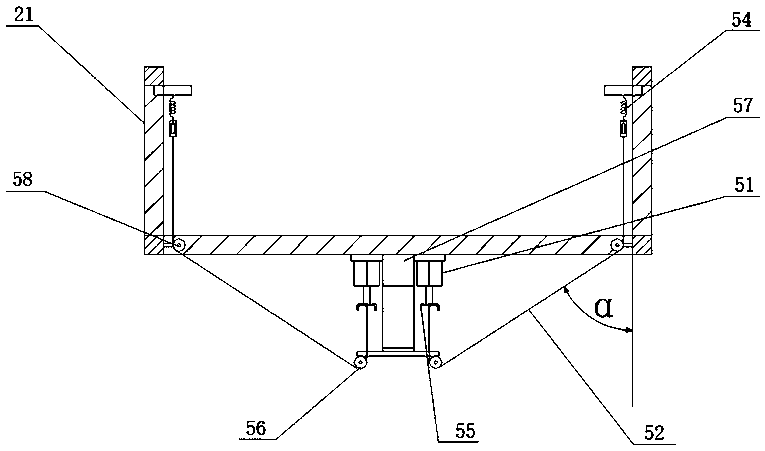

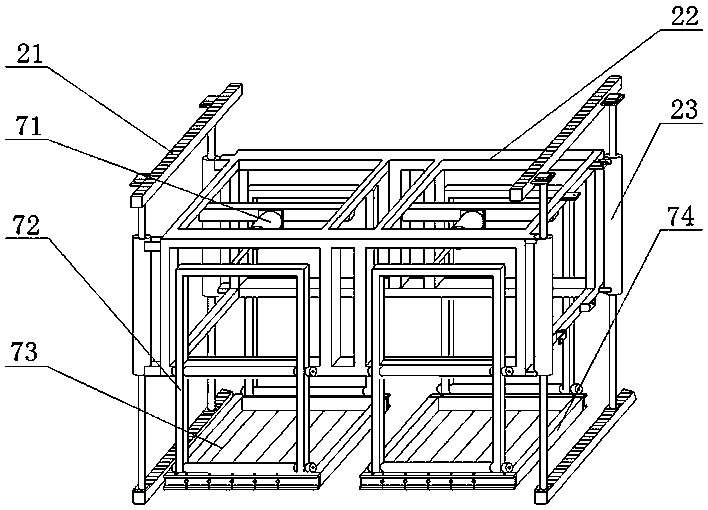

[0027] As shown in the figure: the embodiment of the present invention provides an anti-shake mobile cutting machine for a self-insulating block assembly line, which includes two parallel slide rails 1 and a slide rail 1 for self-insulating block A cutting machine 2 for cutting the body 4, the cutting machine 2 includes a frame, a traveling mechanism for driving the movement of the cutting machine 2, a cross-cutting mechanism for cutting the upper and lower end faces 5 of the self-insulating block body 3, and a The utility model is used for cutting off the side end face 6 of the self-insulating block body 3 and dividing the self-insulating block body 3 into blocks.

[0028]Described frame comprises main frame 21, the elevating frame 22 that is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com