Fixture for testing superhigh-temperature tensile property of conductor material and clamping method

A technology of tensile properties and conductor materials, applied in the field of mechanical clamping, can solve the problems of low cooling efficiency of the fixture, unable to meet the requirements of material mechanical properties test, etc., and achieve the effect of good clamping effect, easy operation and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

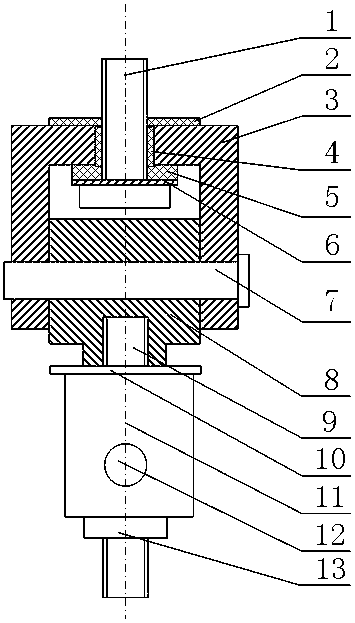

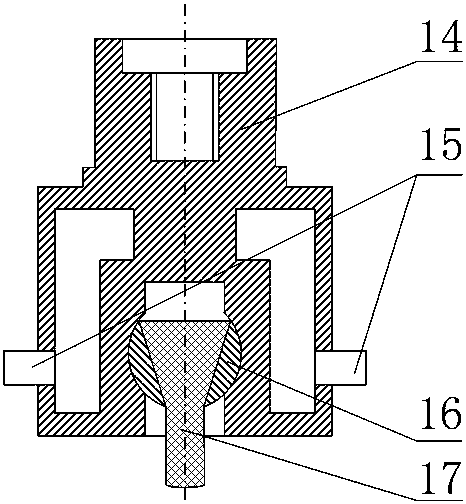

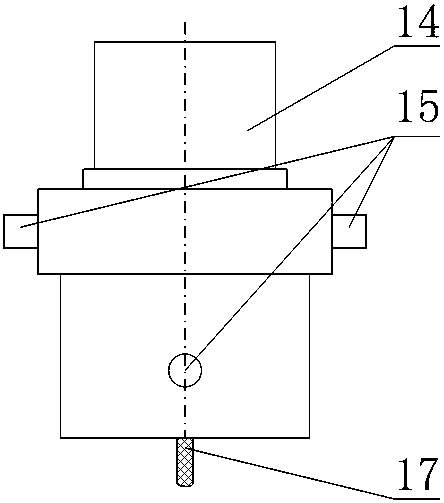

[0034] Specific implementation mode one: as Figure 1-Figure 7 As shown, this embodiment discloses a fixture for testing the ultra-high temperature tensile properties of conductor materials, including an upper water-cooled chuck, an upper tensile joint, a lower water-cooled chuck, and a lower connecting rod;

[0035]The upper water-cooled chuck and the lower water-cooled chuck have the same structure and size, and both include a water-cooled chuck body 14, four water-cooled pipes 15 and four arc-shaped pads 16; the upper tensile joint includes the first A screw 1, the first insulating pad 2, the first connector 3, the first insulating sleeve 4, the second insulating pad 5, the first washer 6, the first pin 7, the first connecting block 8, the second screw 9, the first Two washers 10, the second connecting head 11, the second pin 12 and the second connecting block 13; the lower connecting rod includes a shaft connecting sleeve 18, a second insulating sleeve 19, a third insulati...

specific Embodiment approach 2

[0036] Specific implementation mode two: as image 3 As shown, this embodiment is a further description of Embodiment 1. The difference between every two adjacent water-cooled tubes 15 is 90°, and the two opposite water-cooled tubes 15 are on the same plane, and the two adjacent water-cooled tubes 15 are on different planes, the two water-cooling pipes 15 at the bottom are water inlet pipes, and the two water-cooling pipes 15 at the higher position are water outlet pipes. During the test, circulating cooling water was introduced into the water-cooling pipe 15 .

specific Embodiment approach 3

[0037] Specific implementation mode three: as Figure 4 , Figure 5 As shown, this embodiment is a further description of Embodiment 1. The lower connecting rod also includes four third screws 20; 20 connection, each third screw 20 is insulated from the shaft connection sleeve 18 and the metal positioning plate 22 through the third insulating sleeve 21 (between the upper end of each third insulating sleeve 21 and the head end of the third screw 20 and each A third washer 23 is respectively provided between the lower end of the third insulating sleeve 21 and the nut locked on the third screw 20).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com