Basalt fiber composite containing epoxy resin and preparation method of basalt fiber composite material

A technology of basalt fiber and epoxy resin, which is applied in the field of basalt fiber composite material containing epoxy resin and its preparation, can solve the problems of soft material strength, insufficient strength, short service life, etc., and achieve good flame retardant effect , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

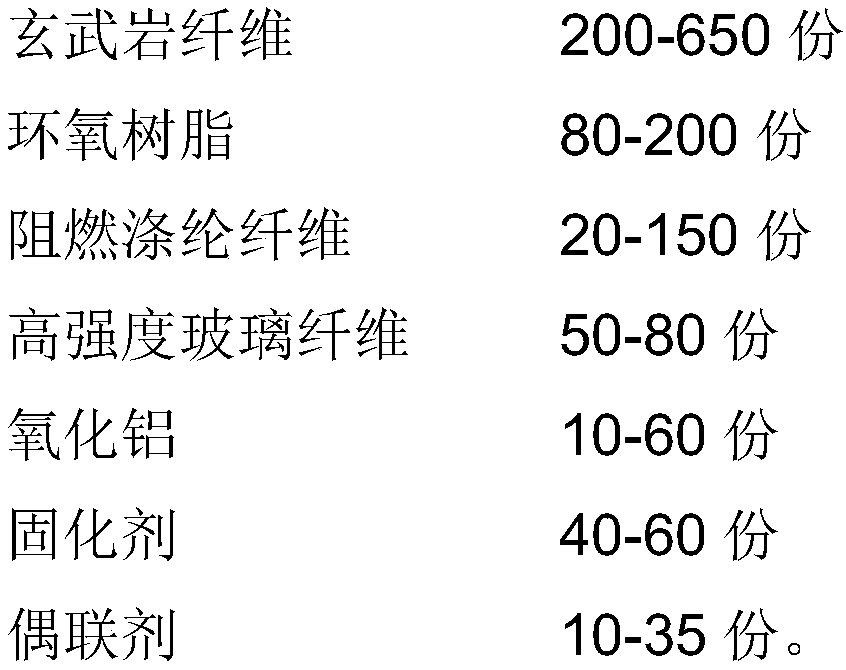

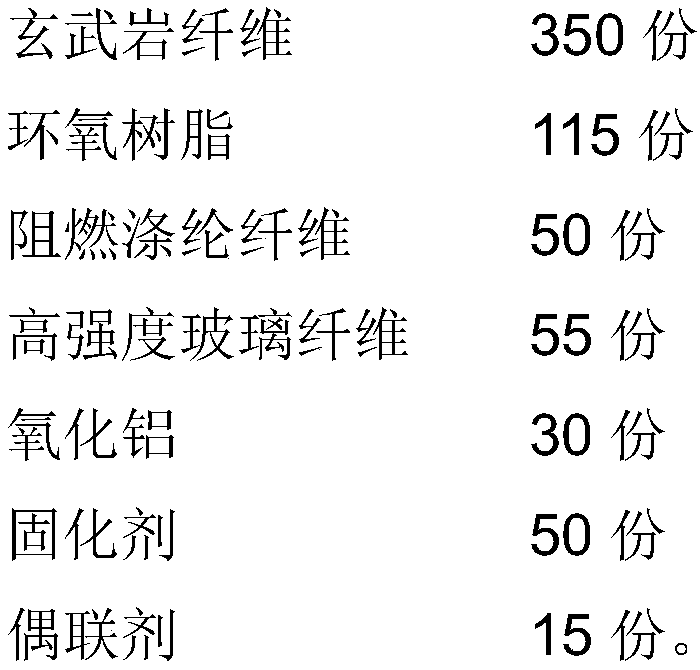

[0026] This embodiment provides a basalt fiber composite material containing epoxy resin, which is characterized in that it contains the following components, and the parts by weight of each component are:

[0027]

[0028] The present invention also provides a method for preparing a basalt fiber composite material containing epoxy resin, the method comprising the steps of:

[0029] Step 1: 115kg of epoxy resin, 50kg of curing agent, 350kg of basalt fiber treated with 15kg of coupling agent, 50kg of flame-retardant polyester fiber, 55kg of high-strength glass fiber, and 30kg of alumina were mechanically mixed and stirred in proportion to form a mixture;

[0030] Step 2: Pour the mixture into a mold coated with a release agent, gradually raise the temperature to the softening point of the epoxy resin and keep it warm for 1.5 hours, continue to raise the temperature to reach the curing temperature of the epoxy resin and keep it warm for 1 hour;

[0031] Step 3: After demoldin...

Embodiment 2

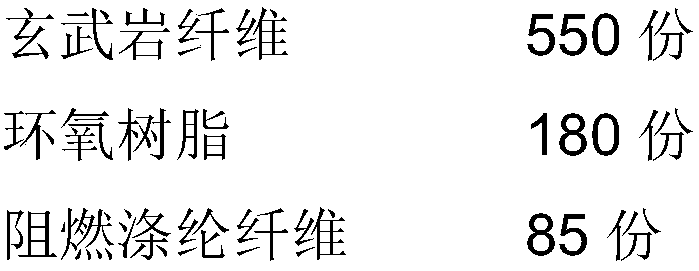

[0035] This embodiment provides a basalt fiber composite material containing epoxy resin, which is characterized in that it contains the following components, and the parts by weight of each component are:

[0036]

[0037] The present invention also provides a method for preparing a basalt fiber composite material containing epoxy resin, the method comprising the steps of:

[0038] Step 1: 550kg of epoxy resin, 180kg of curing agent, 550kg of basalt fiber treated with 30kg of coupling agent, 85kg of flame-retardant polyester fiber, 70kg of high-strength glass fiber, and 50kg of alumina were mechanically mixed and stirred in proportion to form a mixture;

[0039] Step 2: Pour the mixture into a mold coated with a release agent, gradually raise the temperature to the softening point of the epoxy resin and keep it warm for 3 hours, continue to raise the temperature to reach the curing temperature of the epoxy resin and keep it warm for 2 hours;

[0040] Step 3: After demouldi...

Embodiment 3

[0044] This embodiment provides a basalt fiber composite material containing epoxy resin, which is characterized in that it contains the following components, and the parts by weight of each component are:

[0045]

[0046] The present invention also provides a method for preparing a basalt fiber composite material containing epoxy resin, the method comprising the steps of:

[0047] Step 1: 200kg of epoxy resin, 60kg of curing agent, 650kg of basalt fiber treated with 35kg of coupling agent, 150kg of flame-retardant polyester fiber, 80kg of high-strength glass fiber, and 60kg of alumina were mechanically mixed and stirred in proportion to form a mixture;

[0048] Step 2: Pour the mixture into a mold coated with a release agent, gradually raise the temperature to the softening point of the epoxy resin and keep it warm for 2 hours, continue to raise the temperature to reach the curing temperature of the epoxy resin and keep it warm for 1.5 hours;

[0049] Step 3: After demold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com