Composition for glass, glass, preparation method and application thereof

A composition and glass technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems that are difficult to improve, such as stress relaxation and compression stress enhancement, good impact resistance strength, rough surface of touch screen, etc., to achieve improvement Effects of glass stability, high impact strength, and enhanced compressive stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In a second aspect, the present invention provides a method for preparing glass, the method comprising: sequentially mixing, melting, homogenizing, casting and annealing the composition for glass.

[0033] In the method of the present invention, the melting can be carried out in a platinum rhodium crucible. Preferably, the melting conditions include: a temperature of 1450-1630°C and a time of 6-12h. Those skilled in the art can determine the specific melting temperature and melting time according to actual conditions, which are well known to those skilled in the art and will not be repeated here.

[0034] In the method of the present invention, the pouring molding is a conventional pouring molding method in the art, for example, it can be performed in a stainless steel mold, and the specific steps and condition parameters are well-known technologies in the field, and will not be repeated here.

[0035] In the method of the present invention, preferably, the annealing condition...

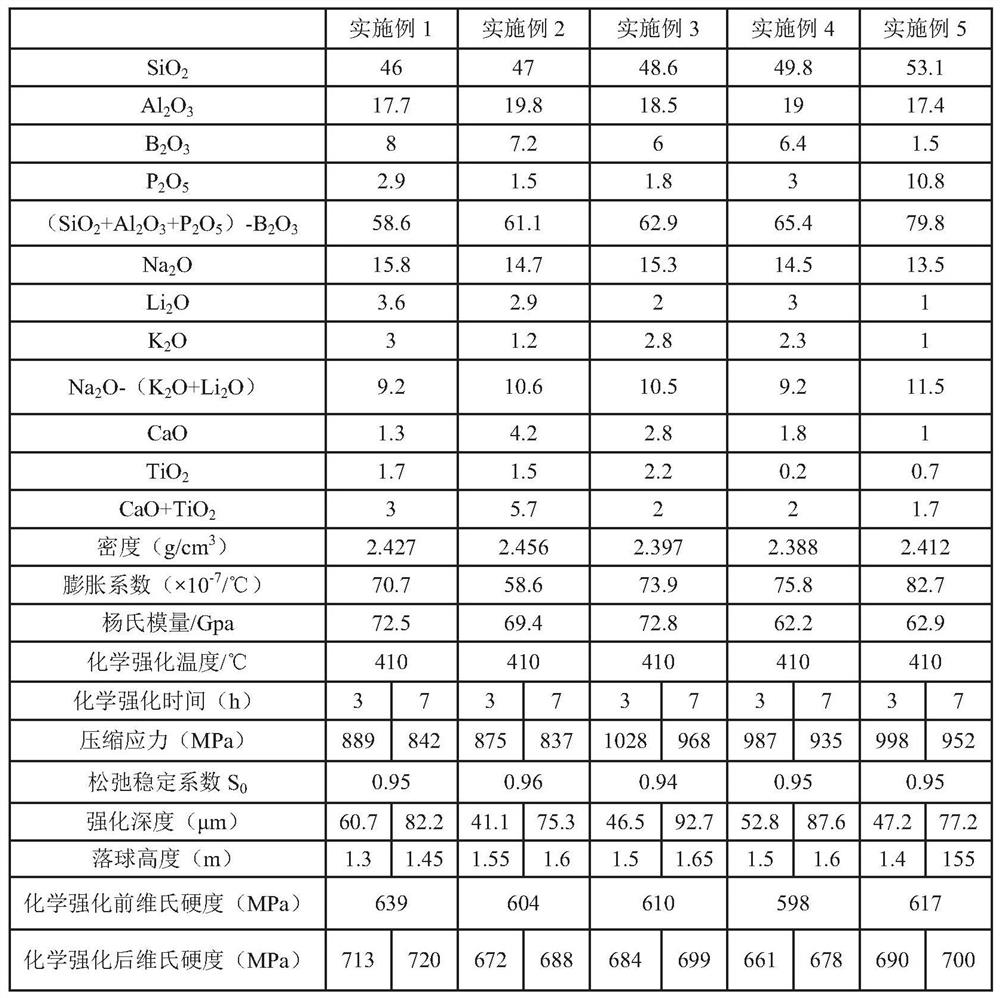

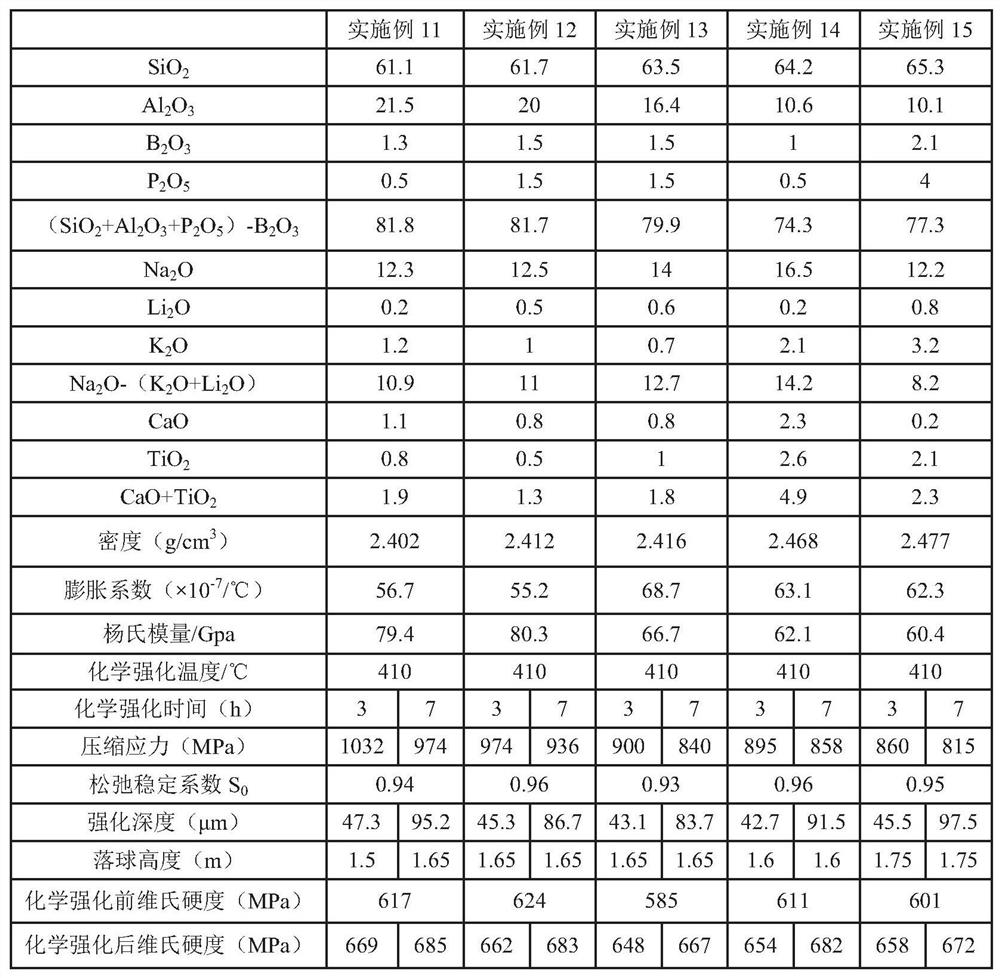

Embodiment 1-18

[0054] Weigh the components according to Table 1-3, mix them, pour the mixture into a platinum-rhodium crucible, and then heat it at 1620°C for 9 hours, and cast the molten glass into a prescribed block glass The glass product is then annealed in an annealing furnace at 640 for 3 hours. Put glassware in pure KNO 3 In the molten strengthening liquid, the glass product is made after chemical strengthening. The various properties of each glass product were measured, and the results are shown in Table 1 to Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com