Energy-saving circular distributary negative pressure cleaning method

A negative pressure and cleaning technology, applied in chemical instruments and methods, solid separation, cyclone devices, etc., can solve the problems of large dust, secondary pollution of the environment, and the production of a large amount of light impurities, so as to reduce energy consumption and overall The effect of reducing mass and total power and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

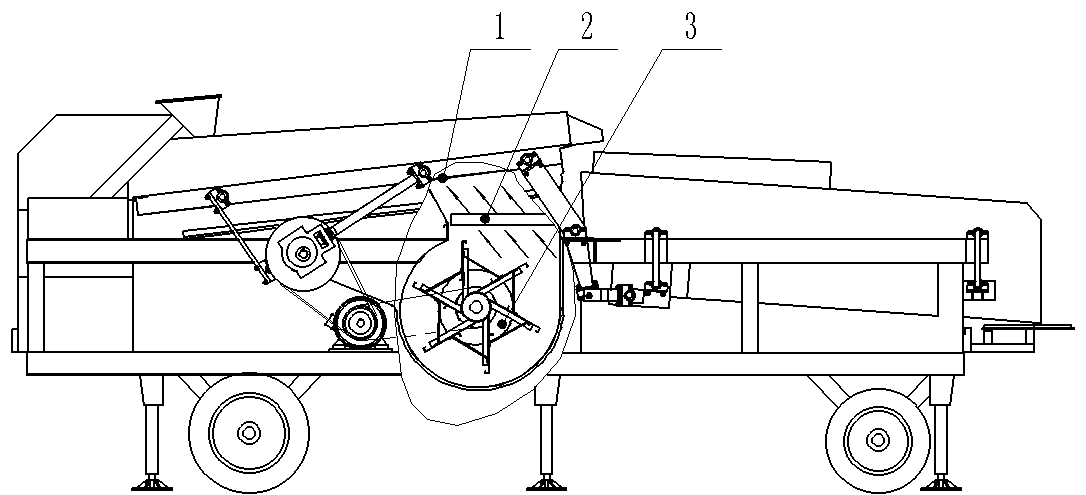

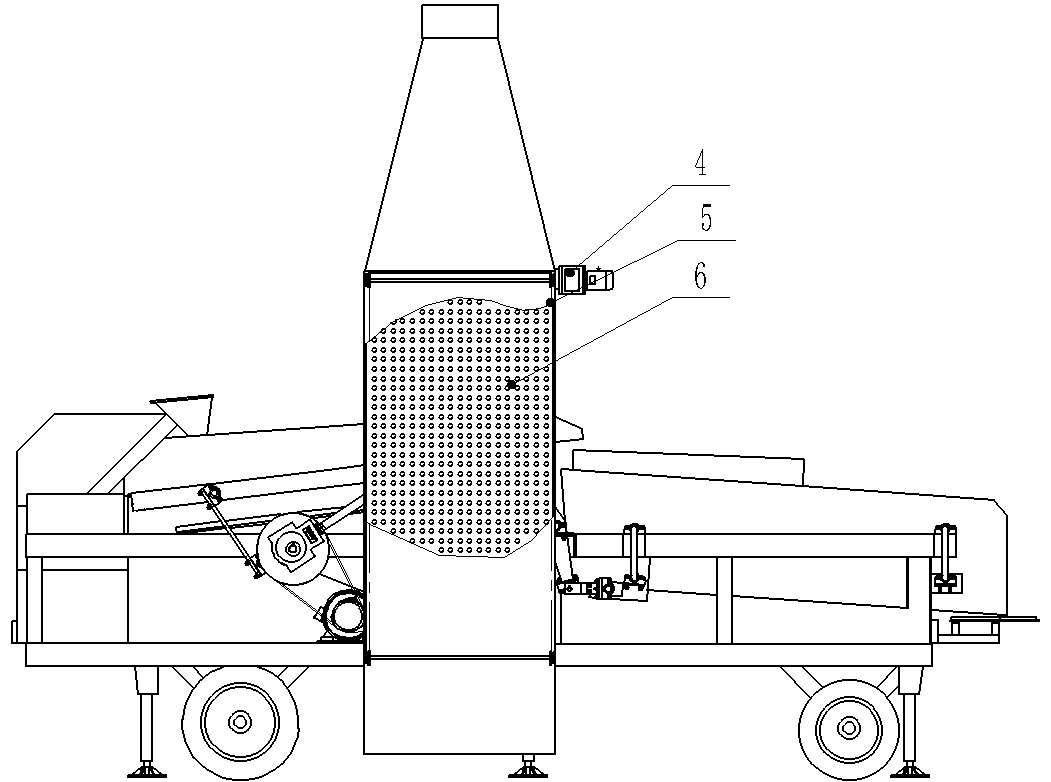

[0016] The suction nozzle in the circulation pipeline is fixed, and the filter screen rotates circularly, such as figure 2 and image 3 shown.

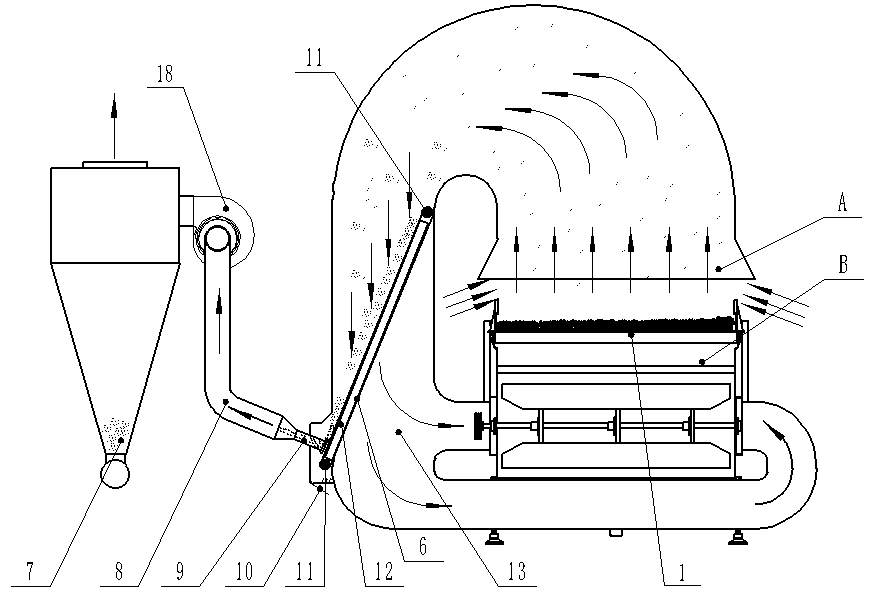

[0017] The main fan 3 is a cross-flow fan that provides the cleaning airflow for the cleaning equipment. The air guide frame 2 blows the cleaning airflow to the part (rectangular area) of the vibrating screen 3 to form a high-speed airflow. Different suspension heights are realized due to the difference in grain specific gravity. During the reciprocating motion of the inclined vibrating screen, different movement directions of high-quality grain, mildewed grain and light impurities are realized. High-quality grain moves upward, and mildewed grain and light impurities move downward, realizing the screening of grain and cleaning the airflow at the same time Mixed with dust and suspended impurities, it enters the circulation pipe 13 through the air inlet A, and a filter screen 6 arranged obliquely and circularly rotates is set in it to...

Embodiment 2

[0019] A fixed filter screen is installed in the circulating air duct, and the suction nozzle moves back and forth, such as Figure 4 and Figure 5 shown.

[0020] The difference from Example 1 lies in the dust removal method in the circulation pipeline 13. The cleaned air flow mixed with dust and suspended impurities passes through the air inlet A, enters the circulation pipeline 13, and passes through the fixed filter screen 18, which is fixed on the screen. On the support frame 12, the impurities and particles adsorbed on the fixed filter screen 18 pass through the moving suction nozzle 15 under the suction of the fan 17 and enter the Shacron dust collector 7 through the telescopic bellows 14 and the air duct 8 for processing. The processing process is the same as Same in embodiment 1, wherein mobile suction nozzle 15 is fixed on the chain of reciprocating movement and annex 5, realizes the reciprocating movement of suction nozzle 15 under the effect of sprocket wheel 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com