Negative electrode for lithium secondary battery, method of manufacturing same and lithium secondary battery using same

A lithium secondary battery, manufacturing method technology, applied in electrode manufacturing, secondary battery, battery electrode and other directions, can solve the problems of low mechanical strength, high reactivity, battery expansion, etc., to suppress the formation of dendrites, high Energy density, the effect of ensuring energy density

Inactive Publication Date: 2018-04-06

KOREA ELECTRONICS TECH INST

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, when the dendrites thus formed continue to grow until they penetrate the separator and come into contact with the anode, an internal short circuit occurs, leading to a phenomenon in which the battery explodes.

Second, since lithium, which is an alkaline metal, has a high reactivity with water, even when some ppm of water is contained in the electrolyte, lithium can react with water to generate heat and gas, which can lead to gas explosion inside the battery. Swells, causing problems with battery stability

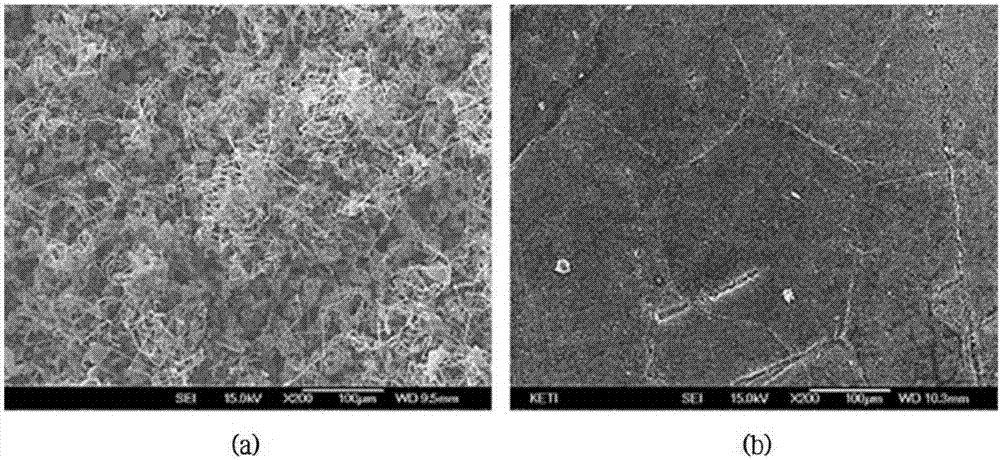

Third, since lithium is soft and has low mechanical strength, its handling is very low when used without additional surface treatment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

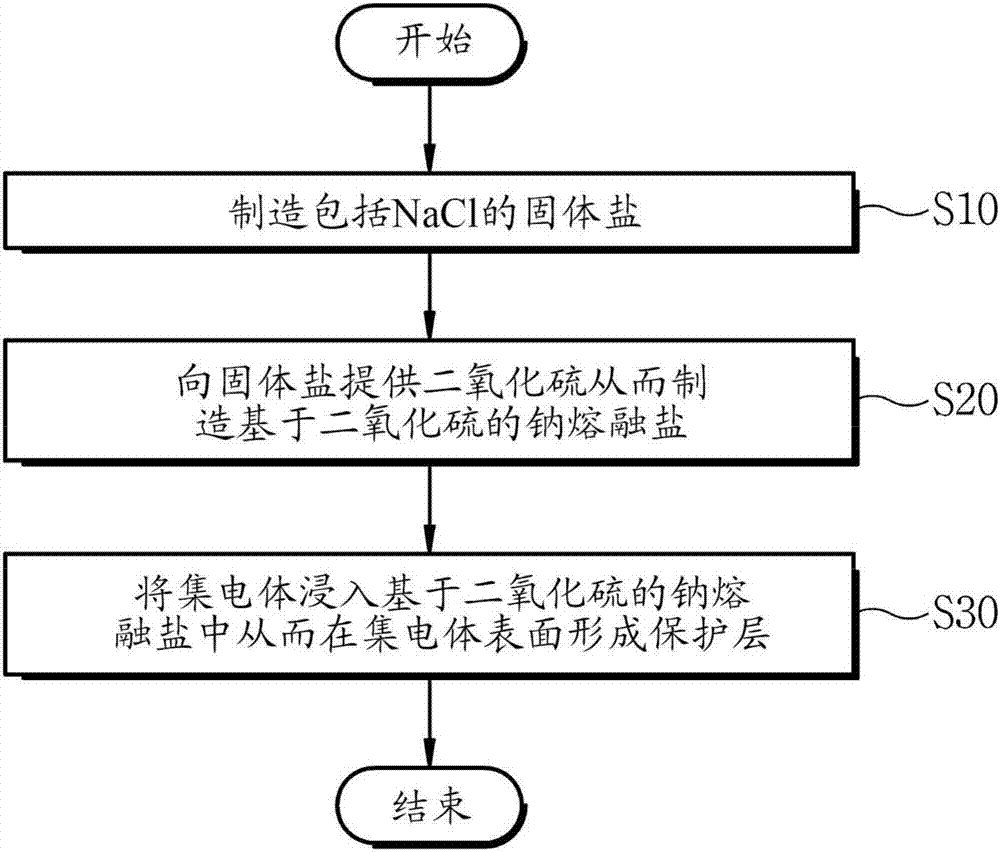

[0056] By combining NaCl and AlCl 3 Mix to make solid salt and provide SO to the solid salt formed 2 thus making NaAlCl 4 -2SO 2 . In addition, the produced NaAlCl 4 -2SO 2 Lithium metal is loaded in the solution, the surface of the lithium metal is reformed, and a lithium secondary battery is manufactured by using the reformed lithium metal as a cathode.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

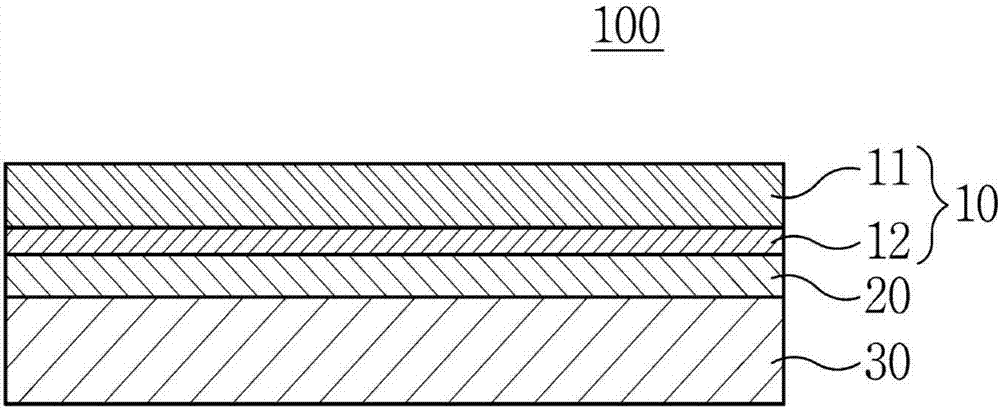

The invention relates to a negative electrode for a lithium secondary battery that can ensure a high energy density, a long-life characteristic, and stability by forming a film on a negative electrodefor a lithium secondary battery and thus suppressing dendrites during electrodeposition, a method of manufacturing the same, and a lithium secondary battery using the same. The method of manufacturing the negative electrode for a lithium secondary battery according to the present invention includes preparing a sulfur dioxide-based sodium molten salt and forming a protective layer on the surface of a current collector by immersing the current collector in the sulfur dioxide-based sodium molten salt.

Description

technical field [0001] The present invention relates to lithium secondary batteries, and more particularly, to devices capable of suppressing dendrites during charge and discharge by forming a film on a cathode for lithium secondary batteries, thereby ensuring high energy density, long life, and stability. A cathode for a lithium secondary battery, a manufacturing method thereof, and a lithium secondary battery using the cathode. Background technique [0002] While the demand for secondary batteries is increasing along with the growth of the IT mobile market, the application fields of secondary batteries are gradually expanding to the market of electric vehicles and energy storage systems. In particular, in order to realize batteries with high energy density such as those used in electric vehicles, it is necessary to develop next-generation lithium batteries with higher energy density than lithium-ion batteries (maximum energy density reaches 250Wh / kg), which is most in line...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M4/1397H01M4/136H01M10/052

CPCH01M4/136H01M4/1397H01M10/052H01M4/0483H01M4/134H01M4/366H01M4/382H01M4/628H01M10/0525Y02E60/10H01M4/0416H01M4/1395H01M10/4235Y02P70/50

Inventor 郑求轸金映俊金翰秀宋珠蕙

Owner KOREA ELECTRONICS TECH INST

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com