Efficient composite vertical cement calcined clinker cooler and cooling method

A cement clinker cooling and cooling method technology, which is applied in the direction of improving energy efficiency, processing discharged materials, and improving process efficiency, can solve the problems of large transmission power consumption, large system air distribution volume, and low cooling efficiency. The effect of long heating time, simple process flow and reliable operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

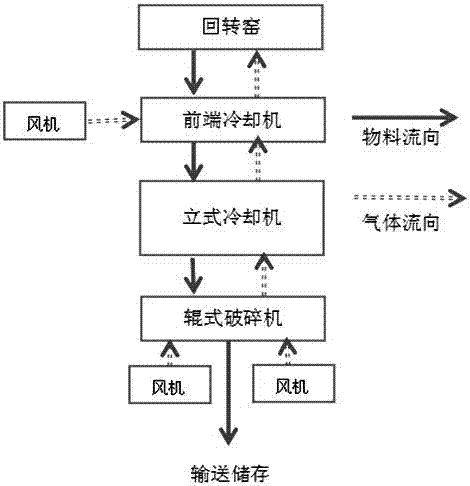

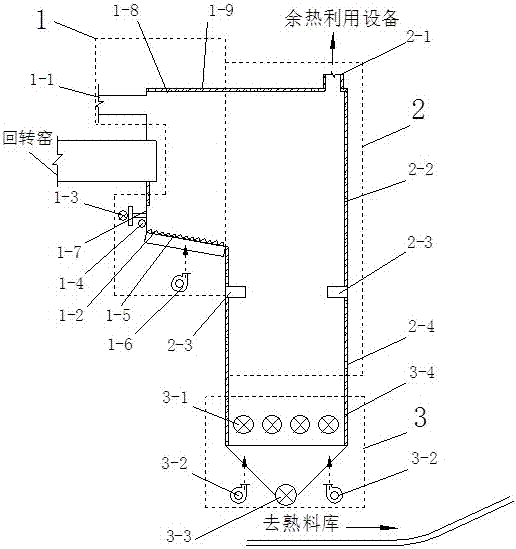

[0028] The invention includes a cement clinker cooler and a cooling method.

[0029] The cement clinker cooler includes: a front-end cooling device 1, a vertical cooling device 2 and a broken air lock device 3; the front-end cooling device is connected to one side of the vertical cooling device, and the front-end cooling device 1 is also connected to the rotary kiln. The vertical cooling device 2 is connected with the waste heat utilization equipment; the crushing air lock device is located in the vertical cooling device 2, the discharge port of the crushing air lock device.

[0030] The front cooling device includes: fixed grate plate 1-2, fixed beam 1-5, air supply device 1-6, air cannon 1-4, snowman device 1-3, front shell 1-7 and castable 1 -8;

[0031] The fixed grate plate 1-2 is fastened on the fixed beam 1-5, the front shell 1-7 and the kiln head cover 1-9 are connected with the secondary air duct 1-1, and the front shell 1-7 is equipped with The snowman device 1-3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com