A kind of sponge type permeable pavement and its production method

A production method and technology for road panels, applied in the field of building materials, can solve problems such as failure to use large-scale utilization, land occupation of slag dumps, environmental pollution and other problems, and achieve the promotion of rational allocation and efficient utilization, control of smog, and protection of nature. The effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

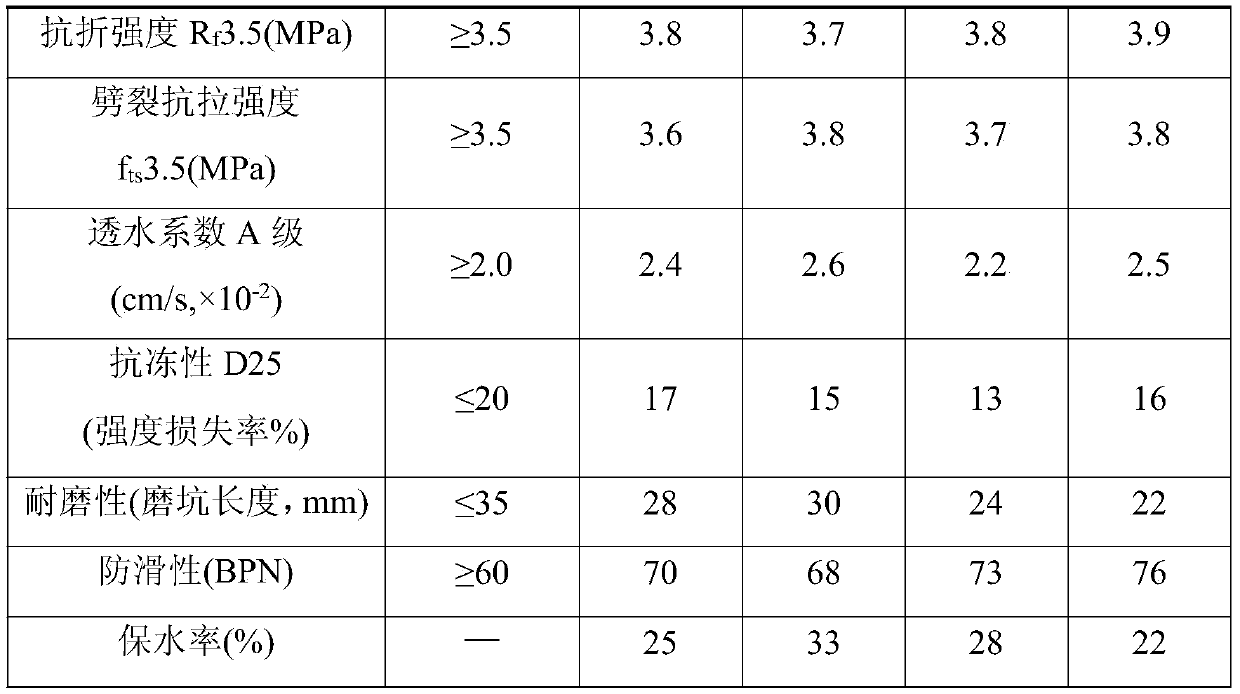

Embodiment 1

[0047] In this embodiment, the sponge-type permeable road slab, its raw material composition includes:

[0048] In parts by mass, 100 parts of base dry mix, 8 parts of water, admixture: 1 part of water reducing agent, 20 parts of surface layer material;

[0049] The base dry mix is prepared by adding expanded slag ceramsite, expanded slag ceramsite and cement in a weight ratio of 45:35:20, putting them into a mixer and stirring for 3 minutes, and mixing evenly;

[0050] The surface layer material is prepared by putting white quartz sand, white cement and pigment in a weight ratio of 80:35:2, stirring in a mixer for 3 minutes, and mixing evenly;

[0051] The preparation method of the sponge type permeable pavement of this embodiment comprises the following steps:

[0052] A. Put the grass-roots dry mix, water and admixture into the mixer, stir for 5 minutes, and mix evenly to obtain the grass-roots material;

[0053] B. Put the base material obtained in step A into the pane...

Embodiment 2

[0058] In this embodiment, the sponge-type permeable road slab, its raw material composition includes:

[0059] In parts by mass, 100 parts of base dry mix, 6 parts of water, additives: 1 part of water reducer, 1 part of early strength agent, 18 parts of surface layer materials;

[0060] The base dry mix is prepared by adding expanded slag ceramsite, expanded slag ceramsite and cement in a weight ratio of 40:30:30, putting them into a mixer and stirring for 3 minutes, and mixing evenly;

[0061] The surface layer material is made of white quartz sand, white cement and pigment in a weight ratio of 60:30:1, put into a mixer and stir for 3 minutes, and mix well;

[0062] The preparation method of the sponge type permeable pavement of this embodiment comprises the following steps:

[0063] A. Put the grass-roots dry mix, water and admixture into the mixer, stir for 5 minutes, and mix evenly to obtain the grass-roots material;

[0064] B. Put the base material obtained in step ...

Embodiment 3

[0069] In this embodiment, the sponge-type permeable road slab, its raw material composition includes:

[0070] In parts by mass, 100 parts of base dry mix, 8 parts of water, admixtures: 1 part of retarder and 1 part of expansion agent, 22 parts of surface layer materials;

[0071] The base dry mix is prepared by adding expanded slag ceramsite, expanded slag ceramsite and cement in a weight ratio of 40:35:25, putting them into a mixer and stirring for 3 minutes, and mixing evenly;

[0072] The surface layer material is made of white quartz sand, white cement and pigment in a weight ratio of 70:35:1, put into a mixer and stir for 3 minutes, and mix well;

[0073] The preparation method of the sponge type permeable pavement of this embodiment comprises the following steps:

[0074] A. Put the grass-roots dry mix, water and admixture into the mixer, stir for 5 minutes, and mix evenly to obtain the grass-roots material;

[0075] B. Put the base material obtained in step A into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com