Method for treating initial fluorine-containing rainwater by adopting magnetic flocculation-adsorption

A technology for initial rainwater and adsorption treatment, applied in filtration treatment, sedimentation treatment, multi-stage water treatment, etc., can solve the problems of low exchange capacity and fluoride removal efficiency of ion exchange resin method, complicated electrodialysis method device, difficult to popularize, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

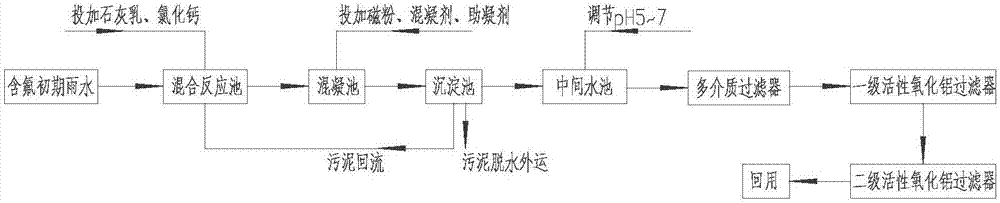

[0024] Such as figure 1 , The processing equipment includes a mixed reaction tank, a coagulation tank, a sedimentation tank, an intermediate tank, a multimedia filter, a primary activated alumina filter, and a secondary activated alumina filter connected in sequence. The intermediate pool is provided with a lifting pump, and the water pump is connected with the water inlet of the multimedia filter through a pipeline. The sedimentation tank is equipped with a sludge return pump to return the bottom sludge of the sedimentation tank to the mixing reaction tank, and the other part of the sludge is pressurized by the sludge pump to the sludge dewatering equipment for dehydration and then shipped out.

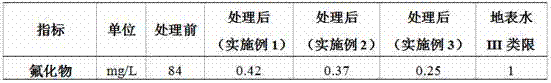

[0025] (1) Mixed reaction: add lime milk to the initial rainwater containing fluoride to adjust the pH to 9, then add calcium chloride at 0.2‰ of the initial rainwater quality containing fluoride, and add magnetic powder at 0.02‰ of the initial rainwater quality containing fluorine (...

Embodiment 2

[0032] (1) Mixed reaction: Add lime milk to the initial rainwater containing fluoride to adjust the pH to 8, then add calcium chloride at 0.3‰ of the initial rainwater quality of fluorine, and add magnetic powder (magnetic powder at 0.02‰ of the initial rainwater quality of fluorine The particle size is 80-200 mesh), mixed for 20 minutes and then enters the coagulation tank;

[0033] (2) Coagulation: In the coagulation tank, add polyaluminum chloride according to 0.3‰ of the initial rainwater quality containing fluorine, and then add coagulant aid according to 0.05‰ of the initial rainwater quality containing fluorine, and coagulate for 20 minutes to obtain a mixed system;

[0034] (3) Sedimentation: Use inclined plate or cooperative sedimentation tank to settle the mixed system for 60 minutes, and take the upper layer water; the sludge return ratio is 1:1.

[0035] (4) pH adjustment: put the upper water into the middle pool, and adjust the pH to 7 with hydrochloric acid or su...

Embodiment 3

[0039] (1) Mixed reaction: add lime milk to the initial fluorine-containing rainwater to adjust the pH to 7, then add calcium chloride at 1‰ of the initial fluorine-containing rainwater quality, and add magnetic powder at 0.03‰ of the initial fluorine-containing rainwater quality (the particle size of the magnetic powder is is 80-200 mesh), mixed for 60 minutes and then enters the coagulation tank;

[0040] (2) Coagulation: In the coagulation tank, add polyaluminum chloride according to 1‰ of the initial rainwater quality containing fluorine, and then add coagulation aid according to 0.1‰ of the initial rainwater quality containing fluorine, and coagulate for 60 minutes to obtain a mixed system;

[0041] (3) Sedimentation: Use inclined plate or cooperative sedimentation tank to settle the mixed system for 60 minutes, and take the upper layer water; the sludge reflux ratio is 5:1.

[0042] (4) pH adjustment: put the upper water into the middle pool, and adjust the pH to 7 with hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com