Edge pressing machine

A technology of edge blanking machine and platen, which is applied in the field of edge blanking machine to achieve the effect of improving edge blanking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

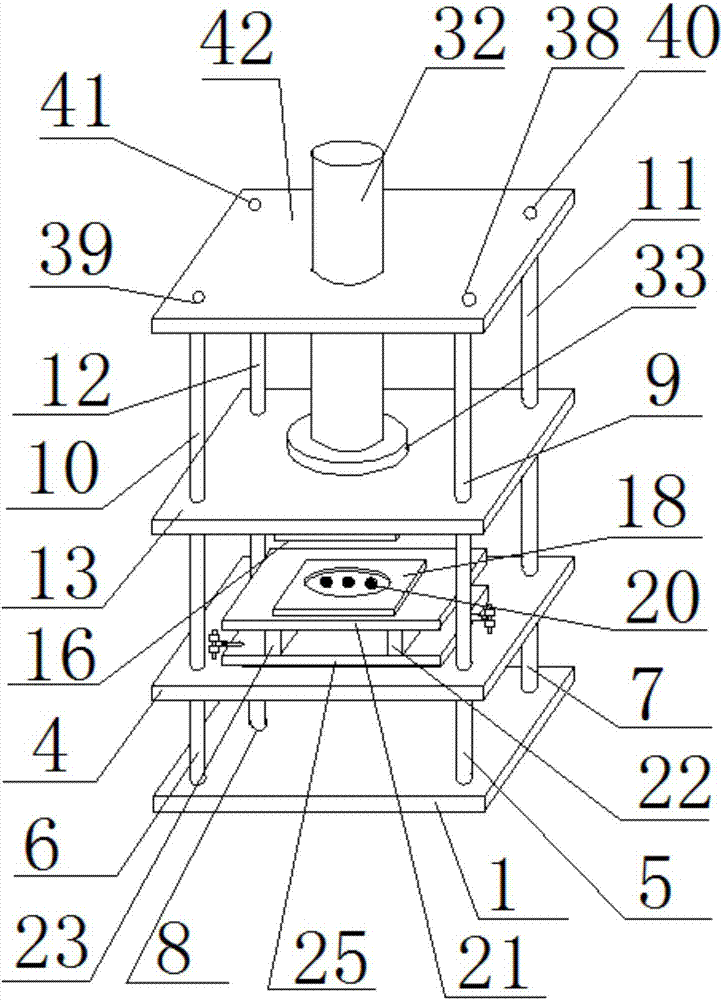

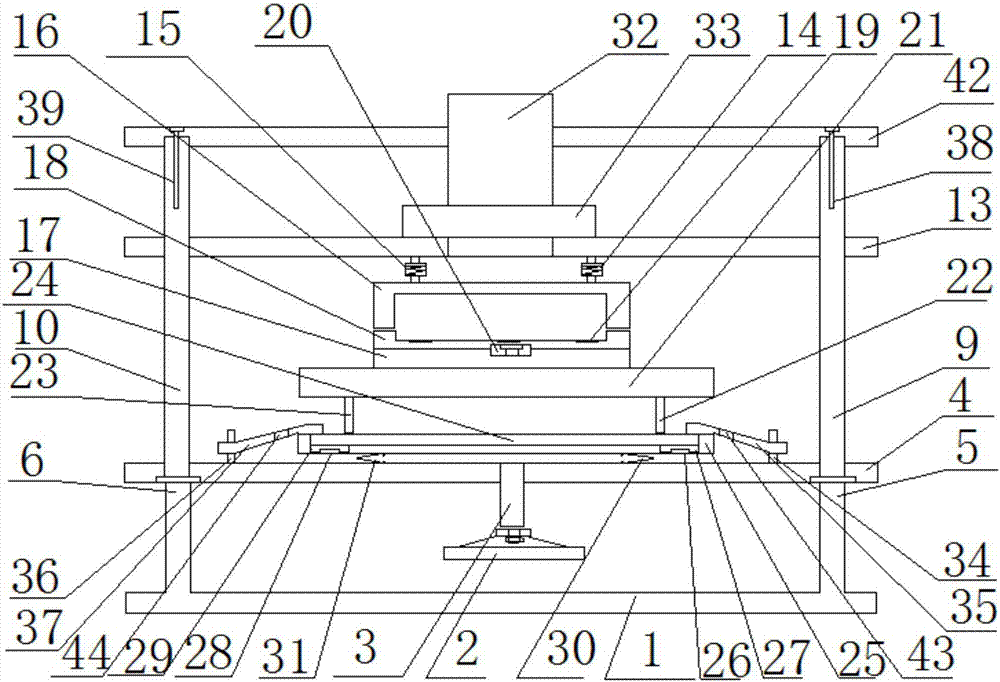

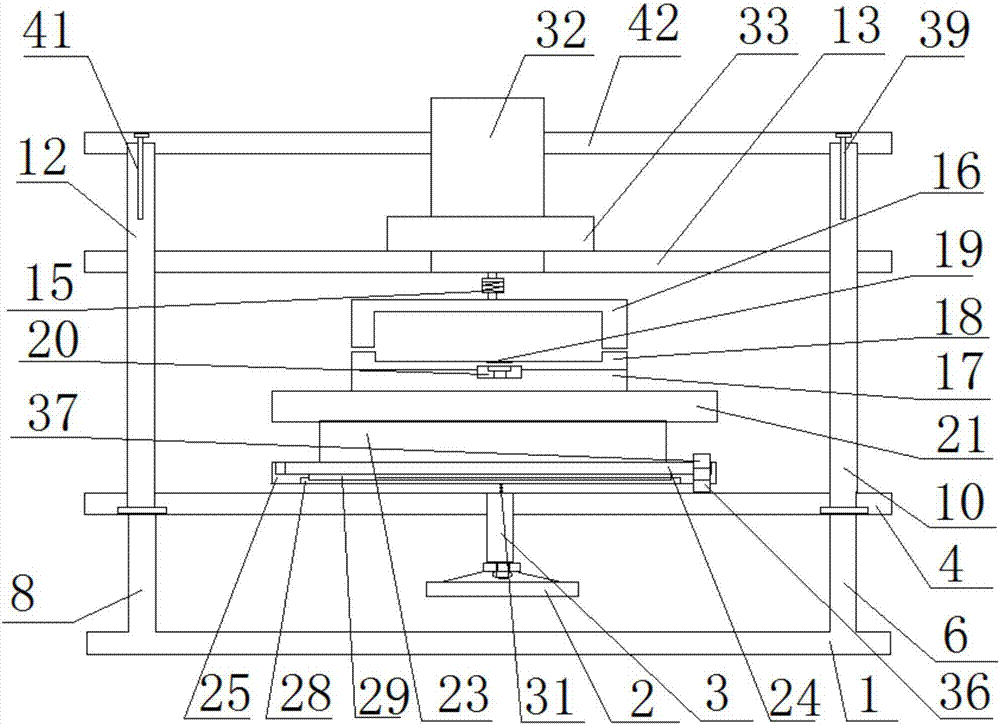

[0073] The present invention will be further described below in conjunction with specific drawings.

[0074] see figure 1 , is a three-dimensional view of an edge pressing machine of the present application. see figure 2 , a front view of an edge pressing machine in this application, see image 3 , the left view of an edge pressing machine of the present application.

[0075] An edge pressing machine, the edge pressing machine includes a carrying device, a positioning device and a driving and guiding device;

[0076] The positioning device is arranged above the carrying device;

[0077] The driving guiding device is arranged above the positioning device;

[0078] The carrying device includes a base 1, a base plate 4, a first support rod 5, a second support rod 6, a third support rod 7 and a fourth support rod 8;

[0079] The bottom ends of the first support rod 5, the second support rod 6, the third support rod 7 and the fourth support rod 8 are fixedly installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com