Beverage bottle sorting device

A sorting device and beverage bottle technology, applied in sorting and other directions, can solve problems such as unfavorable full-automatic production and troubles, and achieve the effects of maintaining stability, preventing overturning, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below with reference to the accompanying drawings, through the description of the implementation examples, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between each part, the role and working principle of each part, etc., will be further described. detailed instructions.

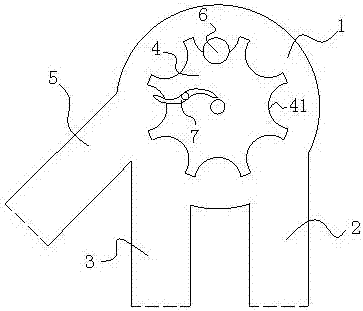

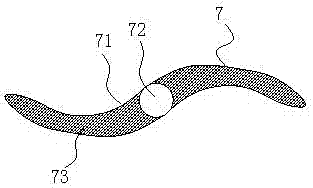

[0012] Such as figure 1 , 2 , the beverage bottle sorting device of the present invention comprises a sorting tray 1, a feed channel 2 and a discharge channel 3 communicated with the sorting tray 1, the sorting tray 1 is provided with a guide turntable 4, and the guide turntable 4 The annular array on the circumference is provided with several guide bayonets 41 adapted to the bottle body of the beverage bottle, and the side of the discharge channel 3 is adjacently provided with a channel 5 for unqualified products, and the guide bayonets 41 of the guide turntable 4 A detection sensor 6 and a rotating lever 7 are also arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com