Preparation method for low-temperature sulfur-resistant denitration catalyst

A denitrification catalyst and low-temperature technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of catalyst denitrification activity reduction and deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

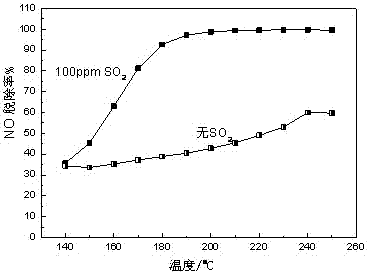

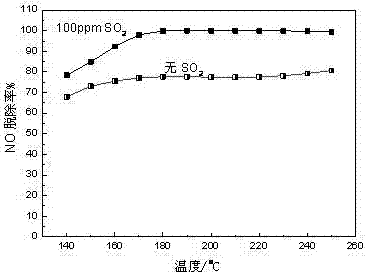

Image

Examples

Embodiment 1

[0014] Example 1 0.05Fe-doped TiO 2 Loaded iron-manganese composite oxide denitration catalyst.

[0015] 20ml of butyl titanate and 70ml of absolute ethanol were mixed to prepare liquid A; 1.19g of ferric nitrate (Fe(NO 3 ) 3 9H 2 O) Solutions are mixed to prepare solution B. Slowly drop liquid A into liquid B, heat it in a water bath at 60°C, stir and reflux, remove the reflux device after adding all liquid A, continue stirring to evaporate water, and make iron-titanium composite organic gel. Put the iron-titanium composite organogel at room temperature for 16 hours, then put it in a drying oven, and dry it at 120°C for 12 hours to obtain a dry glue, and put the dry glue in H 2 The catalyst carrier was obtained by keeping the temperature at 500° C. for 4 hours in an atmosphere sintering furnace. use N 2 The BET specific surface area of the carrier measured by the adsorption-desorption method is 105.27m 2 / g.

[0016] Weigh 5g carrier, 3.62g Fe(NO 3 ) 3 9H 2 O and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com