Nano-composite material catalyst, preparation method, and application thereof

A nano-composite material and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of inability to achieve adsorption and catalytic removal, failure to achieve nano-scale contact, and ozone carbon material erosion. , to achieve the effect of small air resistance, easy control and long-lasting purification function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment relates to a simultaneous removal of ozone, VOCs and / or s-VOCs with MnO x The preparation method of the catalyst that is catalytically active component:

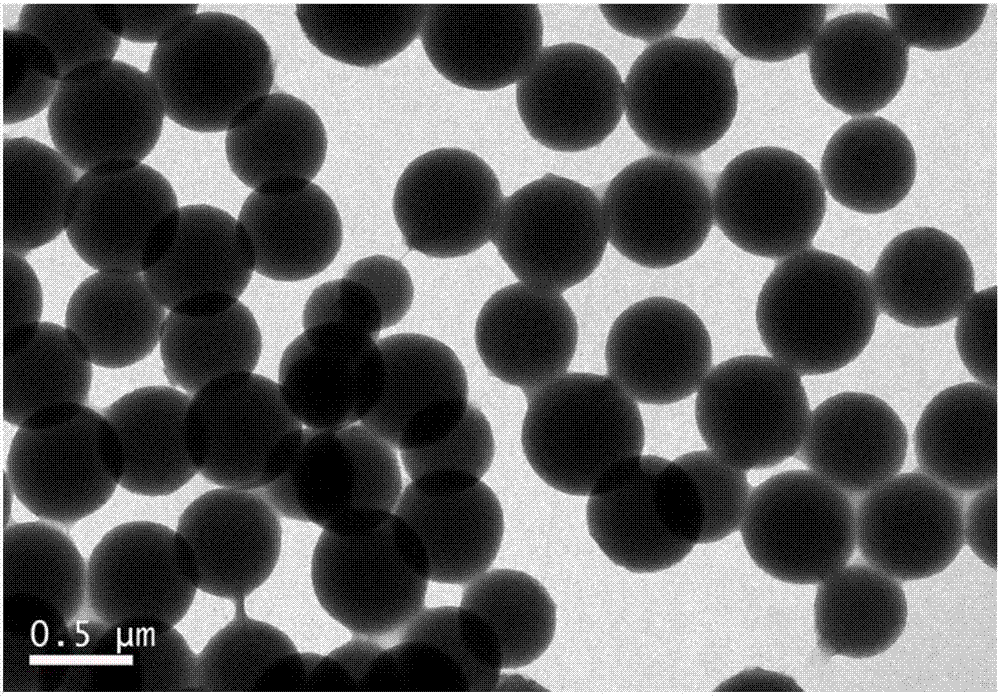

[0032] Step 1, weigh 0.15 g of hydrothermally treated activated carbon or porous carbon nanospheres and ultrasonically disperse them in 50 mL of deionized water, figure 1 It is a schematic diagram of the TEM characterization of the hydrothermally treated porous carbon nanospheres;

[0033] Step 2, weigh 0.125gKMnO 4 , MnSO 4 , Mn(NO 3 ) 2 , MnCl 2 or Mn(Ac) 2 Ultrasonic dispersion in 50 mL deionized water, the KMnO 4 , MnSO 4 , Mn(NO 3 ) 2 , MnCl 2 or Mn(Ac) 2 The solution is slowly added to the hydrothermally treated activated carbon or porous carbon nanosphere solution, and magnetically stirred for 1 hour;

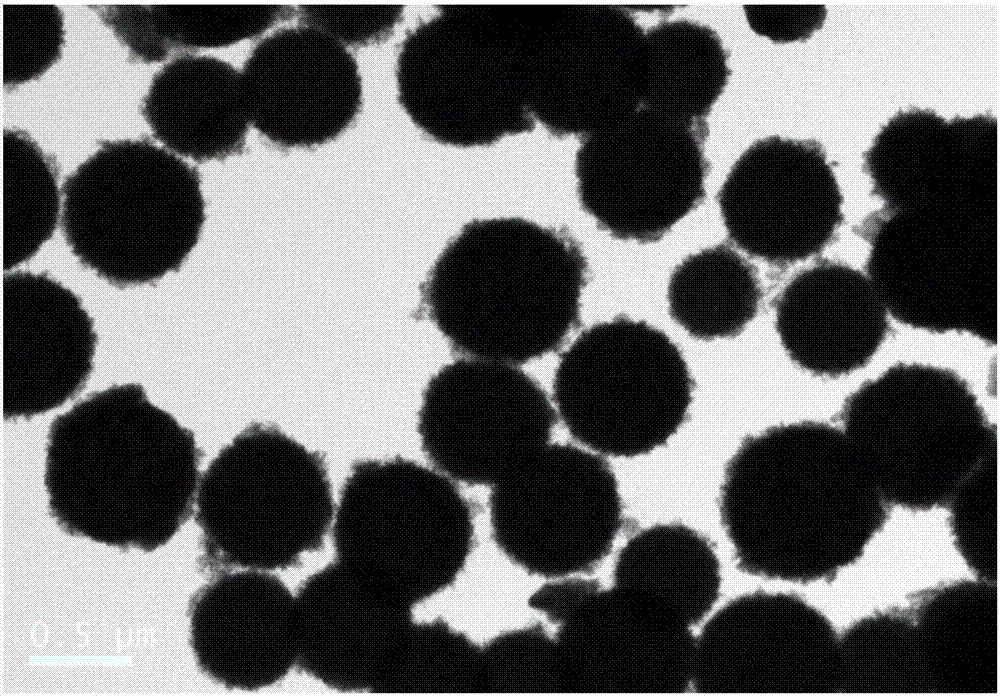

[0034] Step 3, the mixed solution after magnetic stirring for 1 hour is washed and dried to obtain a nanocomposite catalyst, figure 2 That is KMnO 4 C@MnO Prepared by Reaction wit...

Embodiment 2

[0043] This embodiment relates to a simultaneous removal of ozone, VOCs and / or s-VOCs with MnO x The preparation method of the catalyst that is catalytically active component:

[0044] Step 1: Weigh 0.15 g of hydrothermally treated activated carbon or porous carbon nanospheres and ultrasonically disperse them in 50 mL of deionized water;

[0045] Step 2, weigh 0.125gKMnO 4 , MnSO 4 , Mn(NO 3 ) 2 , MnCl 2 or Mn(Ac) 2 Ultrasonic dispersion in 50 mL deionized water, the KMnO 4 , MnSO 4 , Mn(NO 3 ) 2 , MnCl 2 or Mn(Ac) 2 The solution is slowly added to the hydrothermally treated activated carbon or porous carbon nanosphere solution, the porous ceramic plate is placed in it, and magnetically stirred for 1 hour;

[0046] In step 3, the porous ceramic plate is taken out, washed and dried to obtain a supported catalyst.

[0047] Implementation effect: the above C@MnO x / The porous ceramic plate-supported catalyst is placed in a wind tunnel with a cross-sectional flow ve...

Embodiment 3

[0053] This embodiment relates to a simultaneous removal of ozone, VOCs and / or s-VOCs with MnO x -NiO x The preparation method of the catalyst that is catalytically active component:

[0054] Step 1: Weigh 0.15 g of hydrothermally treated activated carbon or porous carbon nanospheres and ultrasonically disperse them in 50 mL of deionized water;

[0055] Step 2, weigh 0.125gKMnO 4 , MnSO 4 , Mn(NO 3 ) 2 , MnCl 2 or Mn(Ac) 2 Ultrasonic dispersion in 50 mL deionized water, the KMnO 4 The solution is slowly added to the hydrothermally treated activated carbon or porous carbon nanosphere solution, and magnetically stirred for 1 hour;

[0056] Step 3, weigh 0.23gNi(NO 3 ) 2 Ultrasonic dispersion in 50mL deionized water;

[0057] Step 4, Ni(NO 3 ) 2 The solution was added thereto and stirred for 3h;

[0058] In step five, the mixed solution is washed and dried to obtain a nanocomposite catalyst.

[0059] Implementation effect: 0.1g of the above C@MnO x -NiO x The nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com