A kind of carbon quantum dot/titanium dioxide composite photocatalytic material and its preparation method and application

A composite photocatalysis and titanium dioxide technology, applied in the field of environmental photocatalysis, can solve problems such as difficult and uniform loading, and achieve the effects of increasing contact probability, improving efficiency, and improving adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

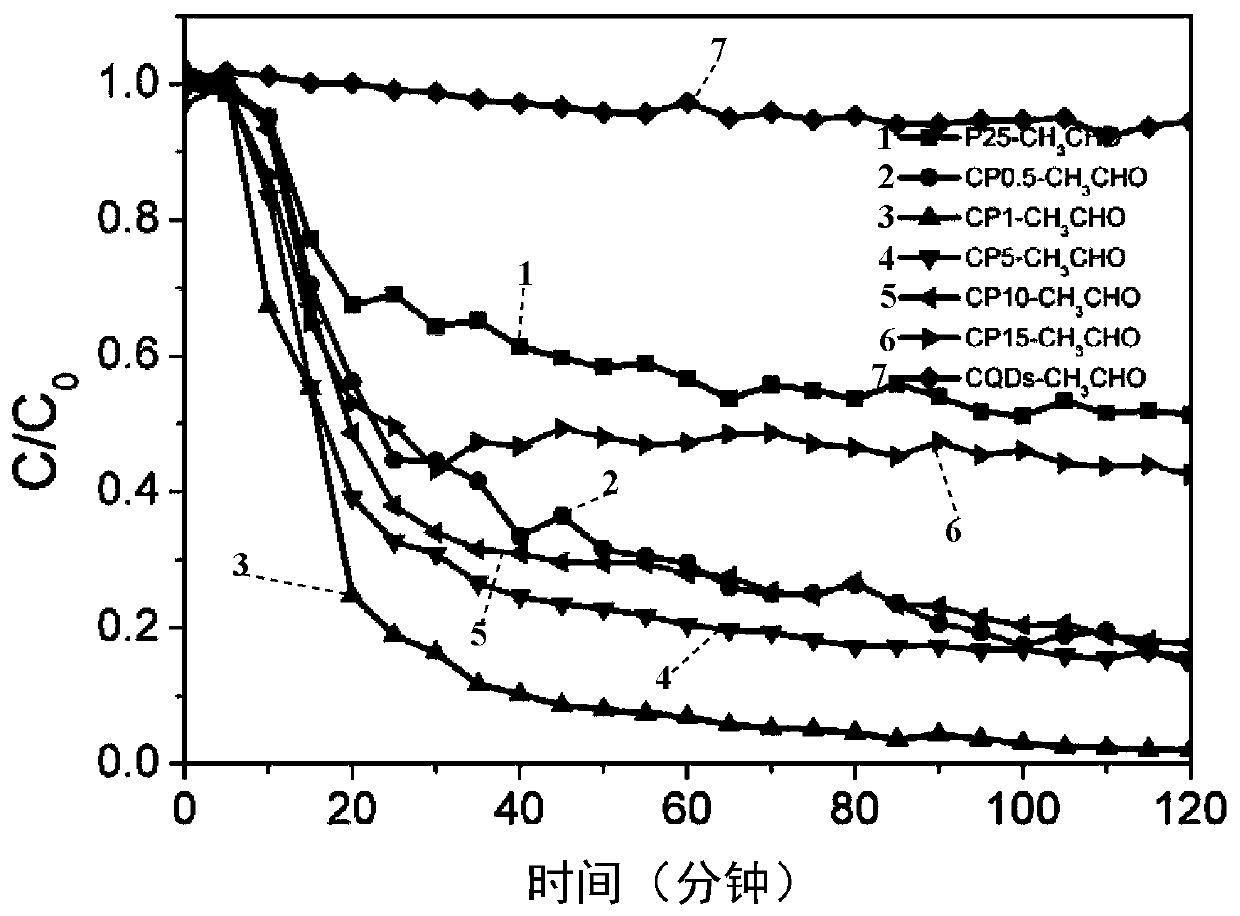

[0072] Weigh 0.005g of urea and 0.005g of citric acid and dissolve them in 30ml of deionized water, stir for 10min, then weigh 1g of commercial titanium dioxide P25 and add it to the mixture of urea and citric acid, ultrasonically disperse for 40min to obtain a uniformly mixed dispersion. Then the dispersion was transferred to a 50mL polytetrafluoroethylene hydrothermal kettle, and the hydrothermal reaction was carried out at 180°C for 6h. After the hydrothermal kettle was naturally cooled to room temperature, the product was washed three times with ionized water and three times with absolute ethanol in a centrifugal washing manner. The centrifugation speed was 7000rpm, and the centrifugation time was 10min each time. The above product was put into a vacuum oven at 80° C. for 12 hours in vacuum, and the solid was ground to obtain a carbon quantum dot / titanium dioxide composite photocatalytic material (referred to as CQDs / P25, wt.%=0.5%).

[0073] Take 0.12g of the above-mentio...

Embodiment 2

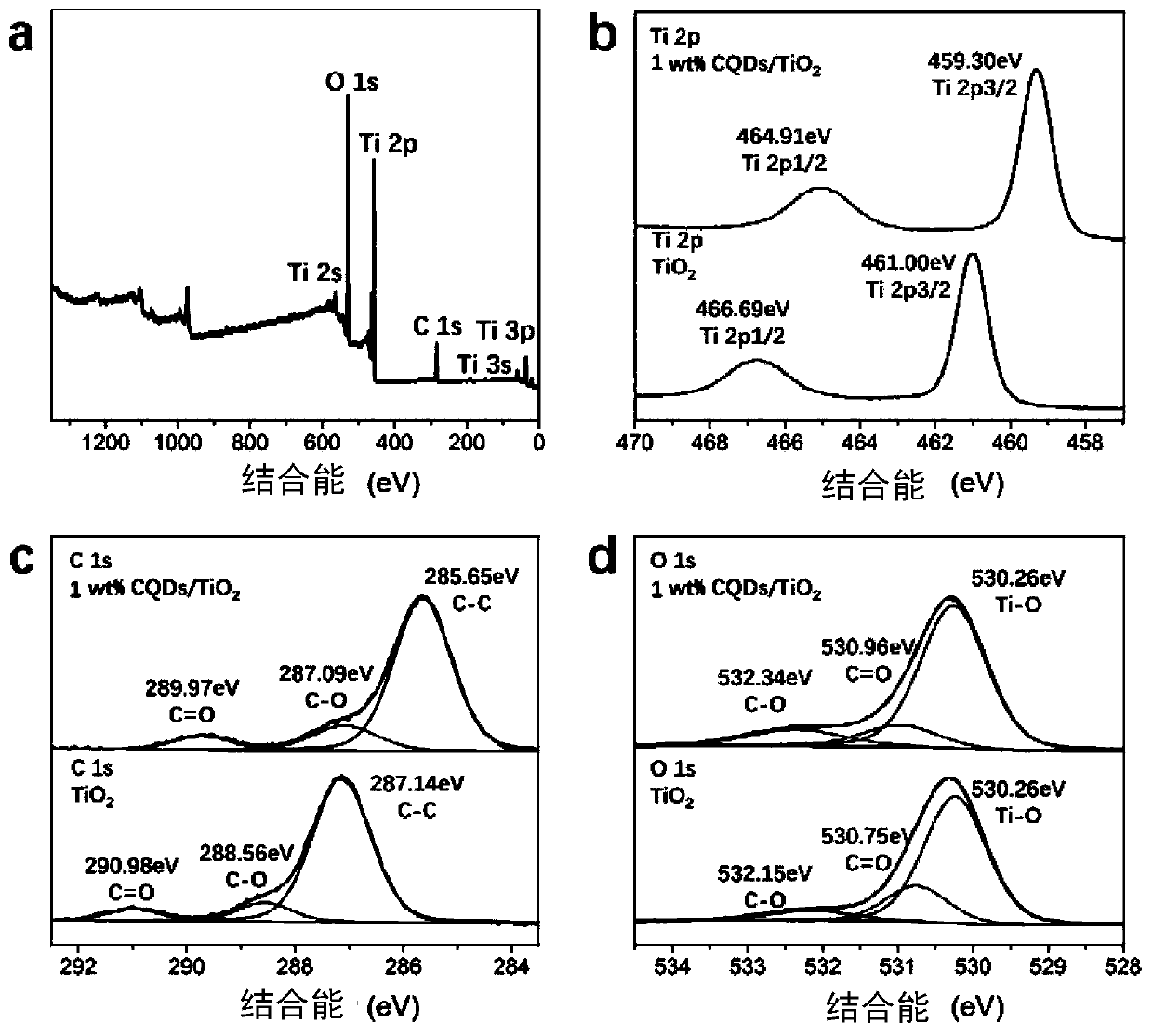

[0075] Weigh 0.01g of urea and 0.01g of citric acid and dissolve them in 30ml of deionized water, stir for 10min, then weigh 1g of commercial titanium dioxide P25 and add it to the mixture of urea and citric acid, and ultrasonically disperse for 40min to obtain a uniformly mixed dispersion. Then the dispersion was transferred to a 50mL polytetrafluoroethylene hydrothermal kettle, and the hydrothermal reaction was carried out at 180°C for 6h. After the hydrothermal kettle was naturally cooled to room temperature, the product was washed three times with centrifugal washing mode ion water and three times with absolute ethanol, the centrifugal speed was 7000rpm, and the centrifugal time was 10min each time. The above product was put into a vacuum oven at 80°C for 12 hours, and the solid was ground to obtain a carbon quantum dot / titanium dioxide composite photocatalytic material (referred to as CQDs / P25, wt.%=1%). figure 2The TEM figure of the carbon quantum dots / titanium dioxide ...

Embodiment 3

[0078] Weigh 0.05g of urea and 0.05g of citric acid and dissolve in 30ml of deionized water, stir for 10min, then weigh 1g of commercial titanium dioxide P25 and add it to the mixture of urea and citric acid, ultrasonically disperse for 40min to obtain a uniformly mixed dispersion. Then the dispersion was transferred to a 50mL polytetrafluoroethylene hydrothermal kettle, and the hydrothermal reaction was carried out at 180°C for 6h. After the hydrothermal kettle was naturally cooled to room temperature, the product was washed three times with centrifugal washing mode ion water and three times with absolute ethanol, the centrifugal speed was 7000rpm, and the centrifugal time was 10min each time. The above product was put into a vacuum oven at 80°C for 12 hours, and the solid was ground to obtain a carbon quantum dot / titanium dioxide composite photocatalytic material (referred to as CQDs / P25, wt.%=5%).

[0079] Take 0.12g of the above-mentioned carbon quantum dot / titanium dioxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com