Industrial tail gas smoke dust and formaldehyde comprehensive treatment system and process

A technology for comprehensive treatment of industrial tail gas, applied in the direction of gas treatment, combined devices, chemical instruments and methods, etc., can solve the problems of affecting the adsorption effect of activated carbon, increasing the load of spray water pumps, and increasing the load of dust removal equipment, so as to save labor Maintenance cost, low investment and operation cost, convenient operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

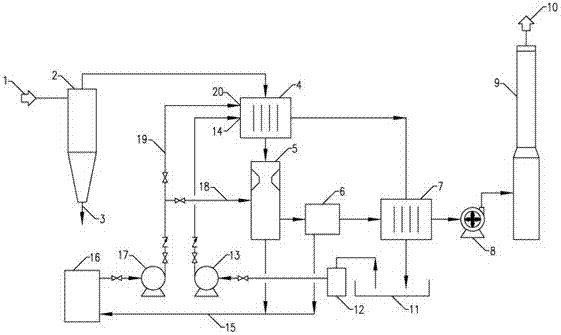

[0039]A comprehensive treatment system for industrial tail gas smoke and formaldehyde, comprising a cyclone dust collector 2, the gas outlet of the cyclone dust collector 2 is connected to the gas inlet of the quencher 4, the gas outlet of the quencher 4 is connected to the gas inlet of the scrubber 5, and the gas outlet of the scrubber 5 is connected to the gas inlet of the scrubber 5 Electric demister 6 gas inlet is connected, electric demister 6 gas outlet is connected to heater 7 gas inlet, heater 7 gas outlet is connected to smoke exhaust fan 8 inlet, smoke exhaust fan 8 outlet is connected to chimney 9 inlet, circulating water pump The inlet of 13 is connected to the outlet of the water diversion tank 12, the inlet of the diversion tank 12 is connected to the circulating pool 11, the outlet of the circulating water pump 13 is connected to the liquid inlet a14 of the quencher 4, the liquid outlet of the quencher 4 is connected to the liquid inlet of the heater 7, and the li...

Embodiment 2

[0041] A comprehensive treatment process for dust and formaldehyde in industrial tail gas, the steps of which are as follows: send industrial tail gas at 120°C to cyclone dust collector 2 for primary dust removal, and collect and process the ash 3 after dust removal; industrial tail gas goes out of cyclone dust collector 2 Entering the quencher 4, when the industrial exhaust gas enters the quencher 4, the circulating water pump 13 sends the low-temperature circulating water at 30°C to the quencher, and the industrial exhaust gas exchanges heat with the low-temperature circulating water. The relative humidity is 20%, that is, the moisture content is 160g / The dew point temperature of kg of industrial exhaust gas is 60°C. After heat exchange, the temperature of industrial exhaust gas is reduced to below 60°C. The condensed water generated by industrial exhaust gas can partially remove the smoke and formaldehyde in the exhaust gas. At the same time, the industrial exhaust gas reach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com