Lotus root digging machine and lotus root digging method

A lotus root digging machine and frame technology, applied in the field of lotus root digging equipment, can solve the problems of cumbersome lotus root digging and high cost of lotus root digging, and achieve the effect of reducing labor intensity, reducing cost of lotus root digging, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

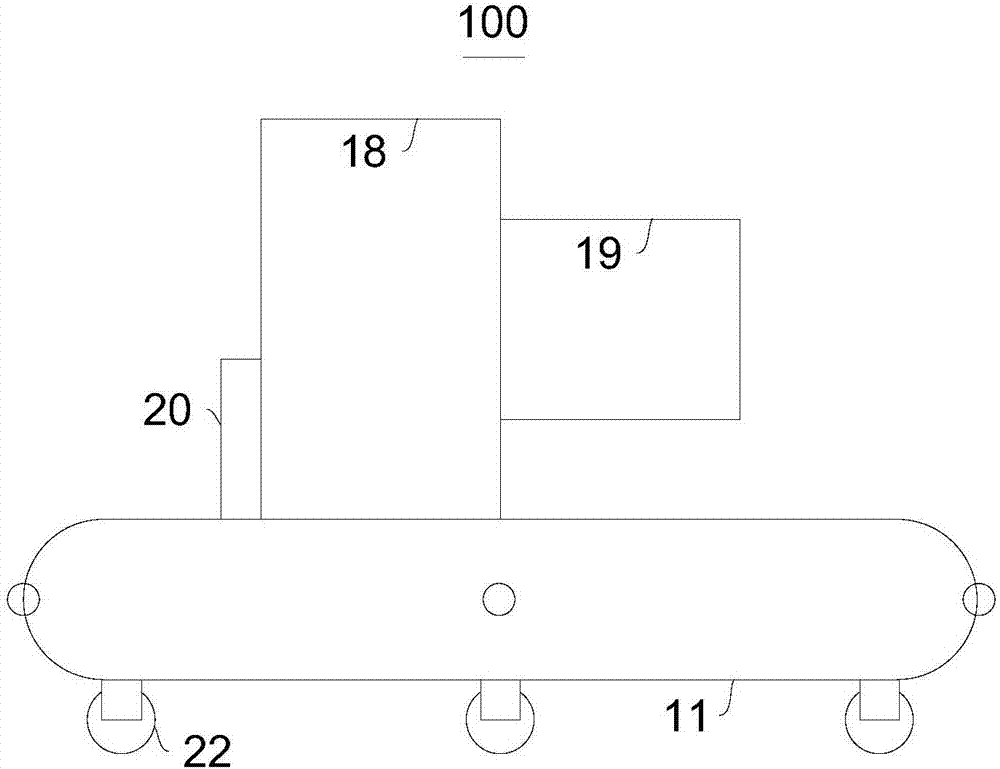

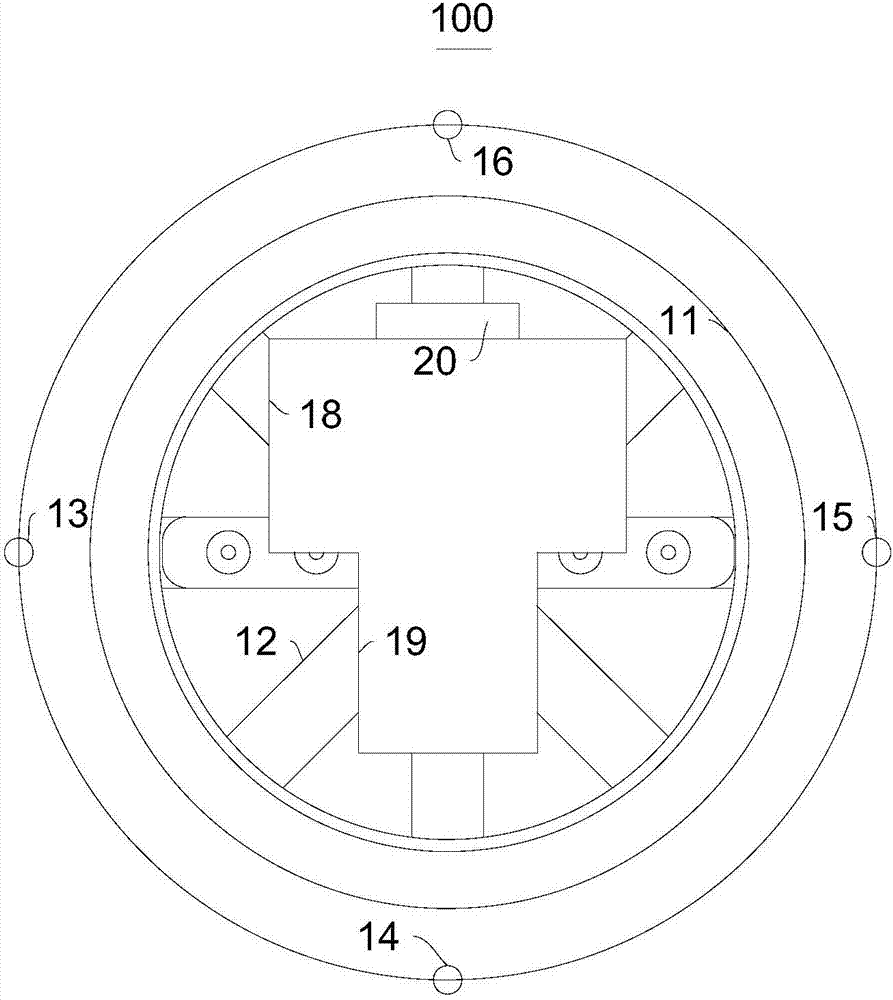

[0057] Please refer to Figure 1-Figure 7 , the present embodiment provides a lotus digging machine 100, which includes:

[0058] The buoy 11, the buoy 11 is circular;

[0059] A frame 12, the frame 12 is connected to the buoy 11;

[0060] The sensor assembly, the sensor assembly includes a first sensor 13, a second sensor 14, a third sensor 15 and a fourth sensor 16, and the first sensor 13, the second sensor 14, the third sensor 15 and the fourth sensor 16 are evenly distributed on the edge of the buoy 11;

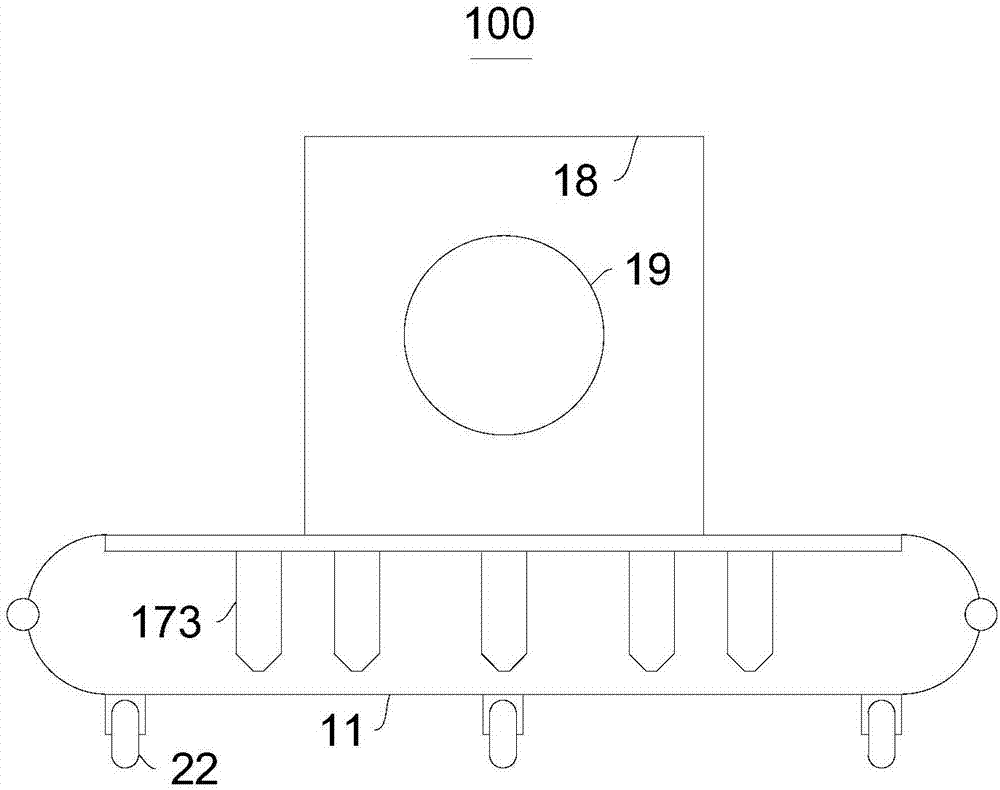

[0061] Working pipeline 17, working pipeline 17 has accommodating cavity 171, and the middle part of working pipeline 17 is provided with rotating part 172, and rotating part 172 is rotatably connected to frame 12, and the bottom of working pipeline 17 is provided with a plurality of and accommodating cavity 171 communicates. Nozzle 173, the parallel direction of a plurality of nozzles 173 is consistent with the length direction of the working pipeline 17, and the spr...

Embodiment 2

[0106] Please refer to Figure 8 , this embodiment provides a lotus root digging method, which uses the aforementioned lotus root digging machine 100, and the structure of the lotus root digging machine 100 can refer to Embodiment 1.

[0107] Digging methods include:

[0108] Put the lotus root digging machine 100 into the square lotus root field, make the first sensor 13 and the second sensor 14 contact the field ridge, make the length direction of the working pipeline 17 be on the line direction of the first sensor 13 and the second sensor 14, the control device 20 receiving the sensing signal of the sensing component and recording it as the initial position of the lotus digging machine 100;

[0109] The control device 20 controls the drive motor 18 to drive the pump 19 to work, so that the nozzle 173 sprays water and performs the lotus digging operation. When the nozzle 173 sprays water, the buoy 11 is driven to move forward along the first preset direction, which is perpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com