Eccentric structure voltage probe

A technology of voltage probe and eccentric structure, which is applied in the direction of measuring electricity, measuring electrical variables, and components of electrical measuring instruments, etc. It can solve problems that affect product installation, use, increase product diameter, increase production cost, etc., and achieve savings Product use space, reasonable design, and the effect of increasing equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

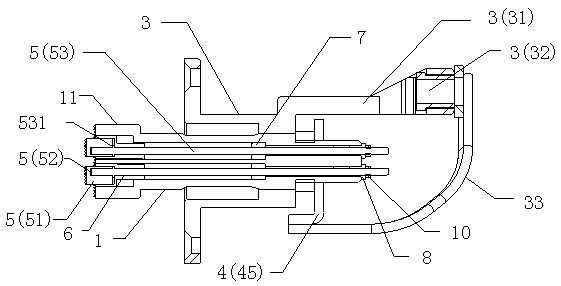

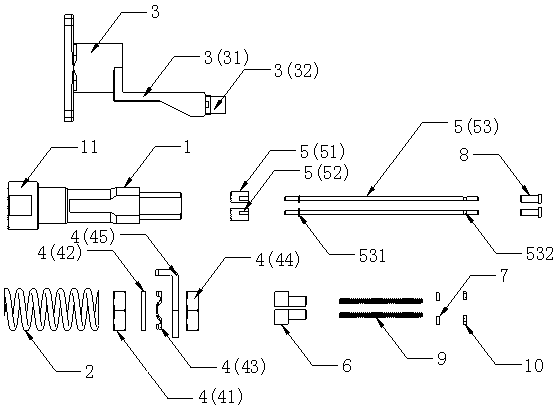

[0025] An eccentric structure voltage probe, as attached figure 2 and 3 As shown, an eccentric structure voltage probe includes a main shaft 1, an elastic element 2, an insulating external member 3, a conductive component 4 and a probe body 5. The inside of the main shaft 1 is hollow, and its outer side is the main shaft probe head from front to back. 11. Elastic element 2, insulating outer connector 3 and conductive component 4;

[0026] The number of 5 probe bodies is 2, the probe head 51 at the front end is connected with the probe rod 53 at the rear end through the internal eccentric fixing groove 52, and the two probe rods 53 pass through the insulating slider 6 at the front end, and the middle one The insulating limiter 7 and the insulating member 8 at the rear end are independently arranged on the inner side of the main shaft 1; the front end of the probe rod is provided with a limit protrusion 531, and the limit protrusion 531 is against the insulating slider 6 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com