Method for predicting initial corrosion time of steel bars in concrete

A technology of initial corrosion time and concrete, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of sensor failure, failure to provide steel bars, and limit wide application, etc., to achieve accurate probability distribution prediction, Environmental conditions have little influence and the effect of avoiding current fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

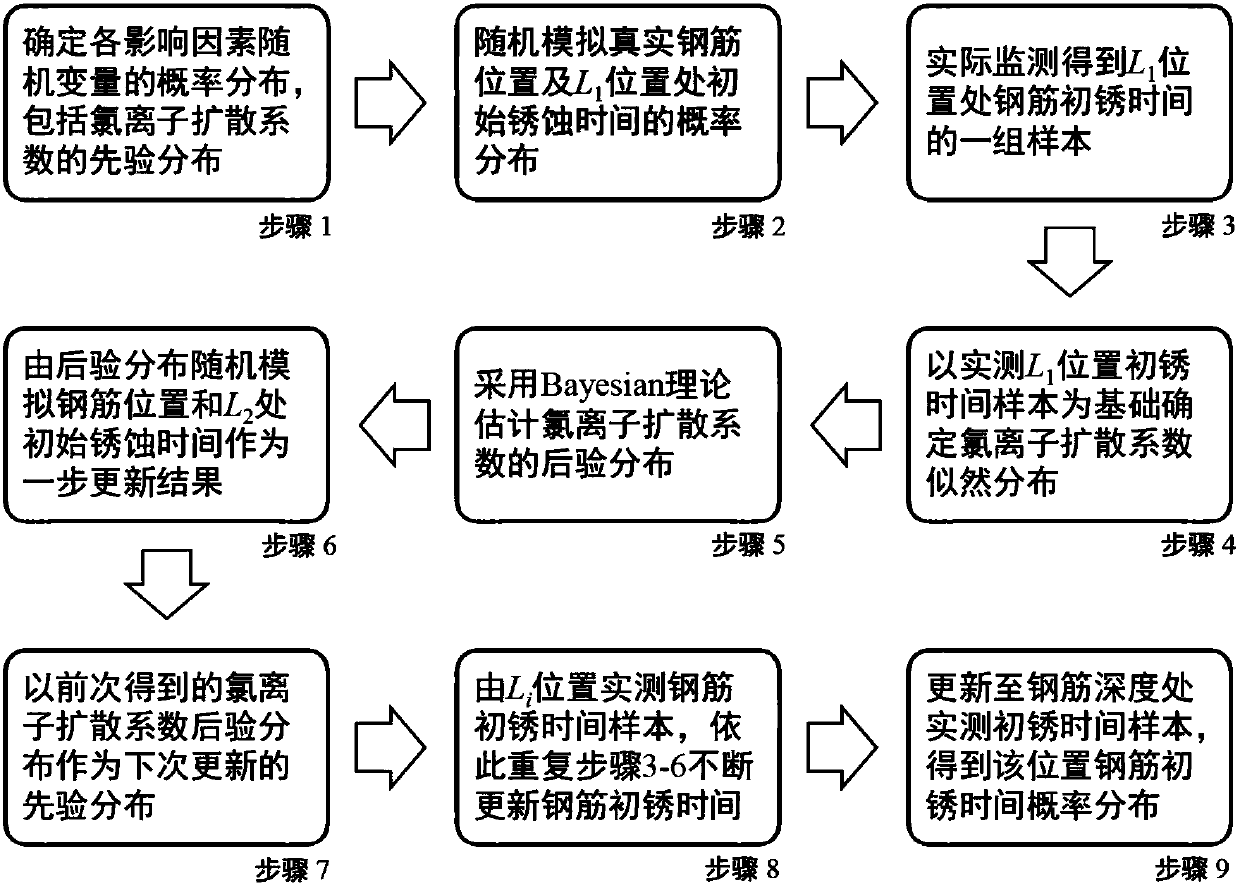

[0052] This embodiment provides a method for monitoring and updating the initial corrosion time of steel bars in concrete based on Bayesian theory.

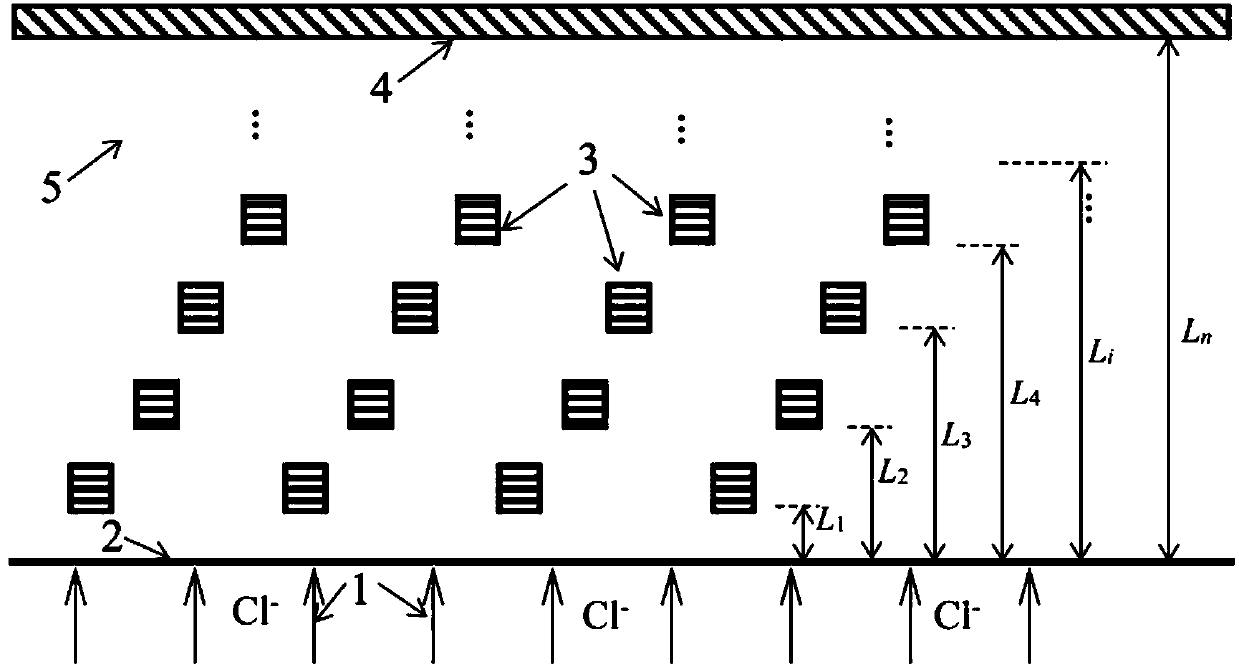

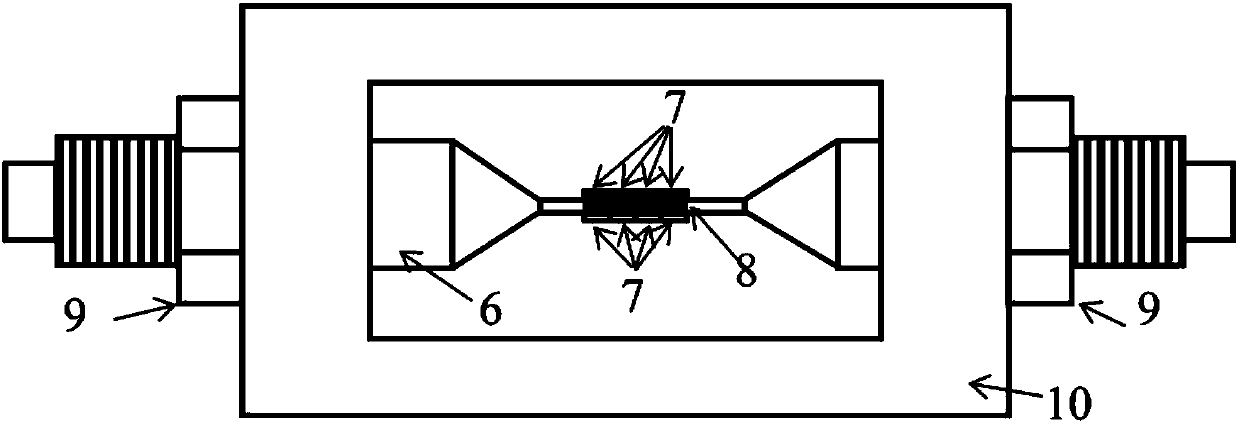

[0053] The monitoring update method is further invented on the basis of the steel bar corrosion monitoring method based on the stress concentration in the plane stress state. Firstly, the thin steel bar of the same material as the steel bar is constructed and the initial strain is applied to make it in the plane stress state, and the corrosion monitoring surface is reserved. Distributed high-spatial-resolution strain measuring points are arranged on the side. Once the corrosion monitoring surface is corroded, local stress concentration occurs, and the measured strain of the distributed high-spatial-resolution strain measuring points changes suddenly. initial corrosion time.

[0054] The time to reach the critical concentration of chloride ions at the reinforcement position in the concrete is affected by the environmental temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com