High-load biological filter tank sewage water treating method capable of backwashing

A sewage treatment method and biological filter technology, which are applied in the field of sewage treatment, can solve the problems of large hydraulic load and easy blockage of the filter, and achieve the effects of small impact on environmental conditions, prevention of filter blockage and dead zone, and simple management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

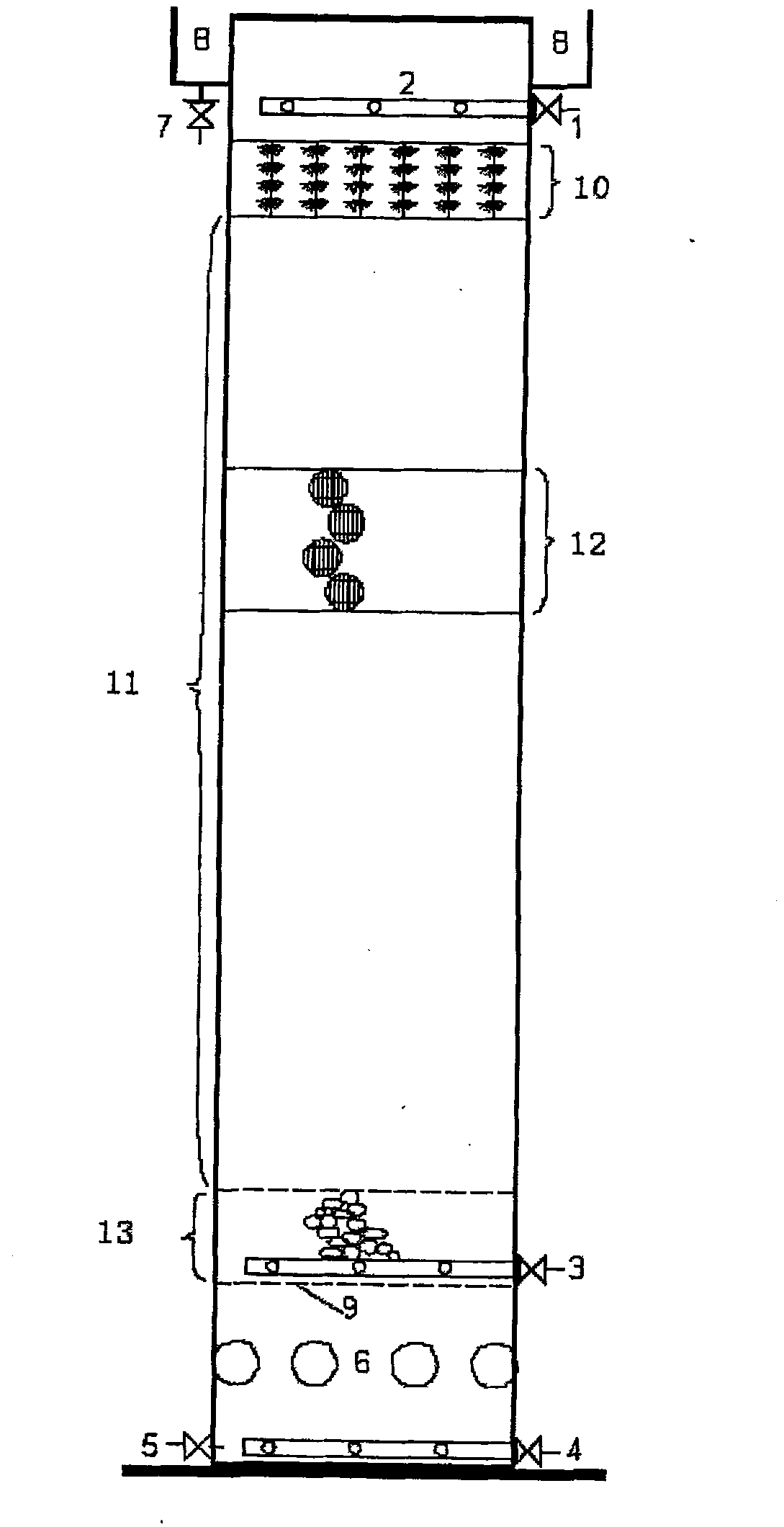

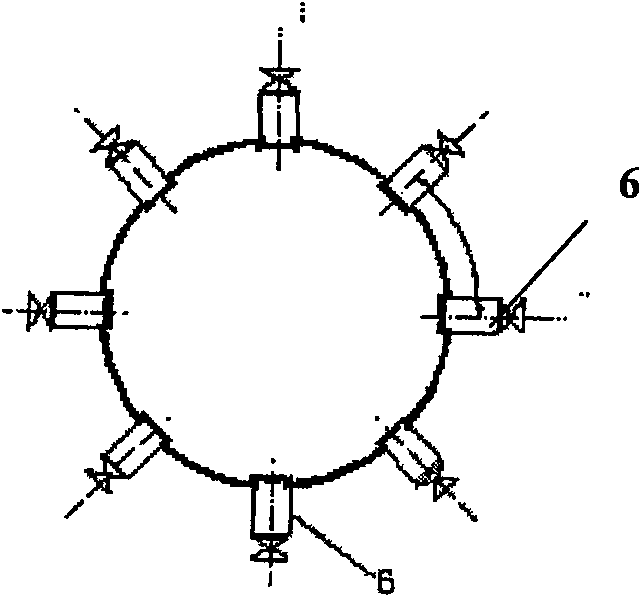

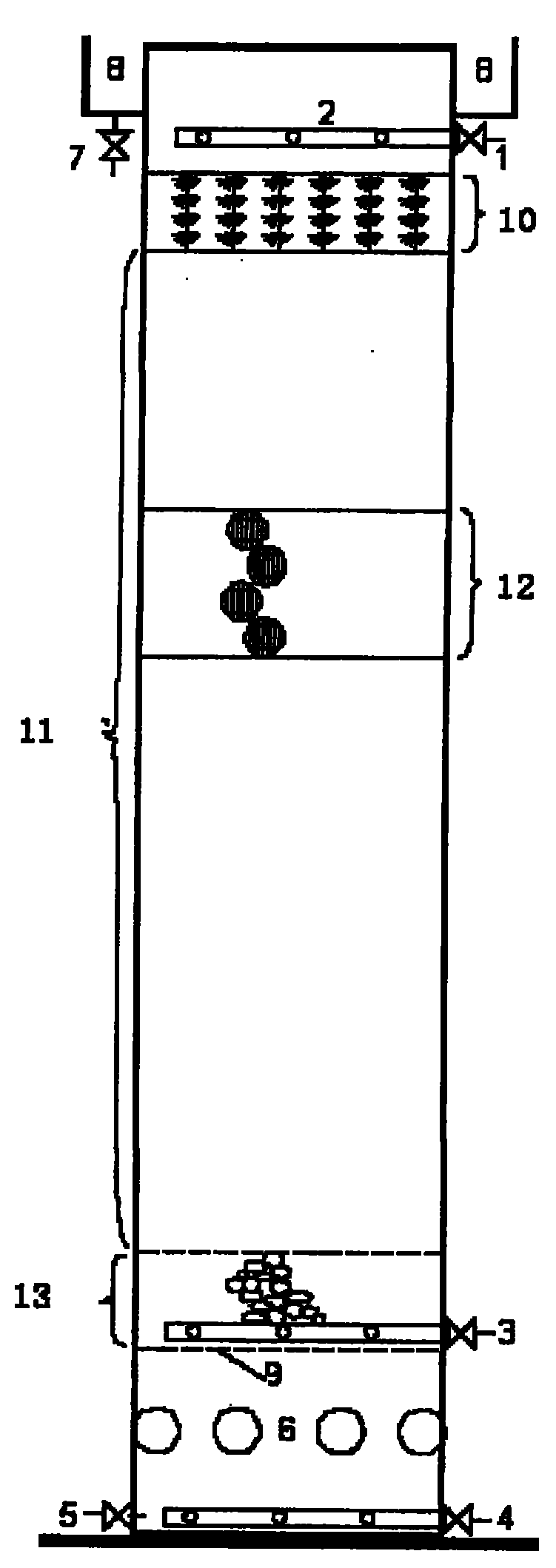

[0020] Such as figure 1 As shown, the specific components used in this embodiment are: water inlet 1, water distributor 2 fixed on the upper part of the filter tank, backwash inlet pipe 3, backwash water inlet pipe 4, water outlet 5, openable and closed edge filter tank Vents 6 evenly distributed on the wall, backwash drains 7, backwash overflow tanks 8, supporting plates 9, reinforced water distribution layers 10, filter material layers 11, anti-clogging layers 12 and supporting layers 13. Installation of the above-mentioned components: set up a ring-shaped backwash overflow tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com