Frisbee throwing device and frisbee throwing method

A technology of flying discs and launching racks, applied in the field of shooting competitions, can solve the problems of high cost, large volume, and inconvenient transportation, and achieve the effect of low cost, small volume, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

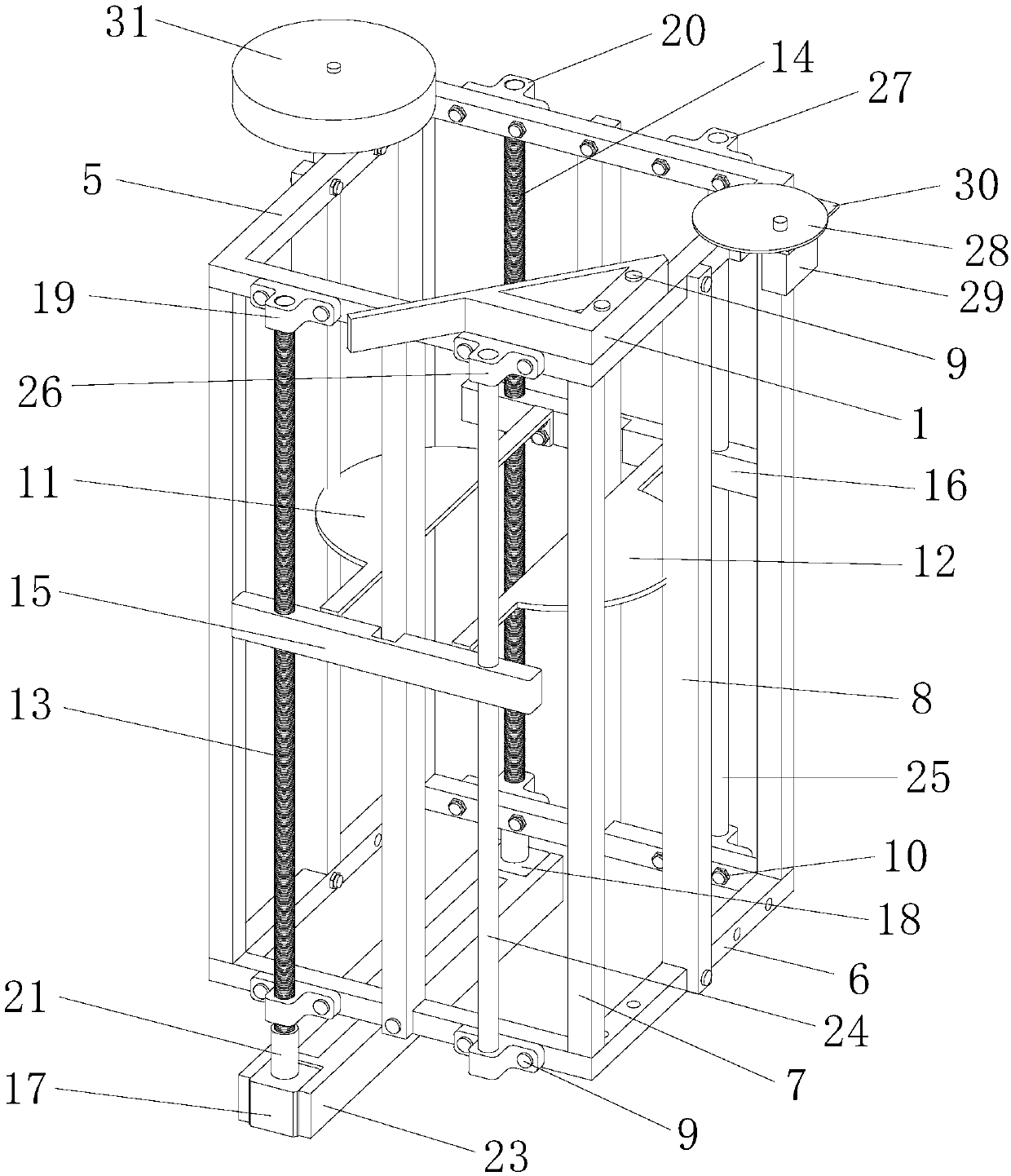

[0034] This embodiment provides a frisbee throwing device, which uses the lifting method to transmit the frisbee, and uses the friction transmission to drive the frisbee to launch. It is not only small in size, quick in assembly, low in cost, and convenient in handling, but also easy to realize the frisbee Fixed point, positioning, fixed speed and continuous launch.

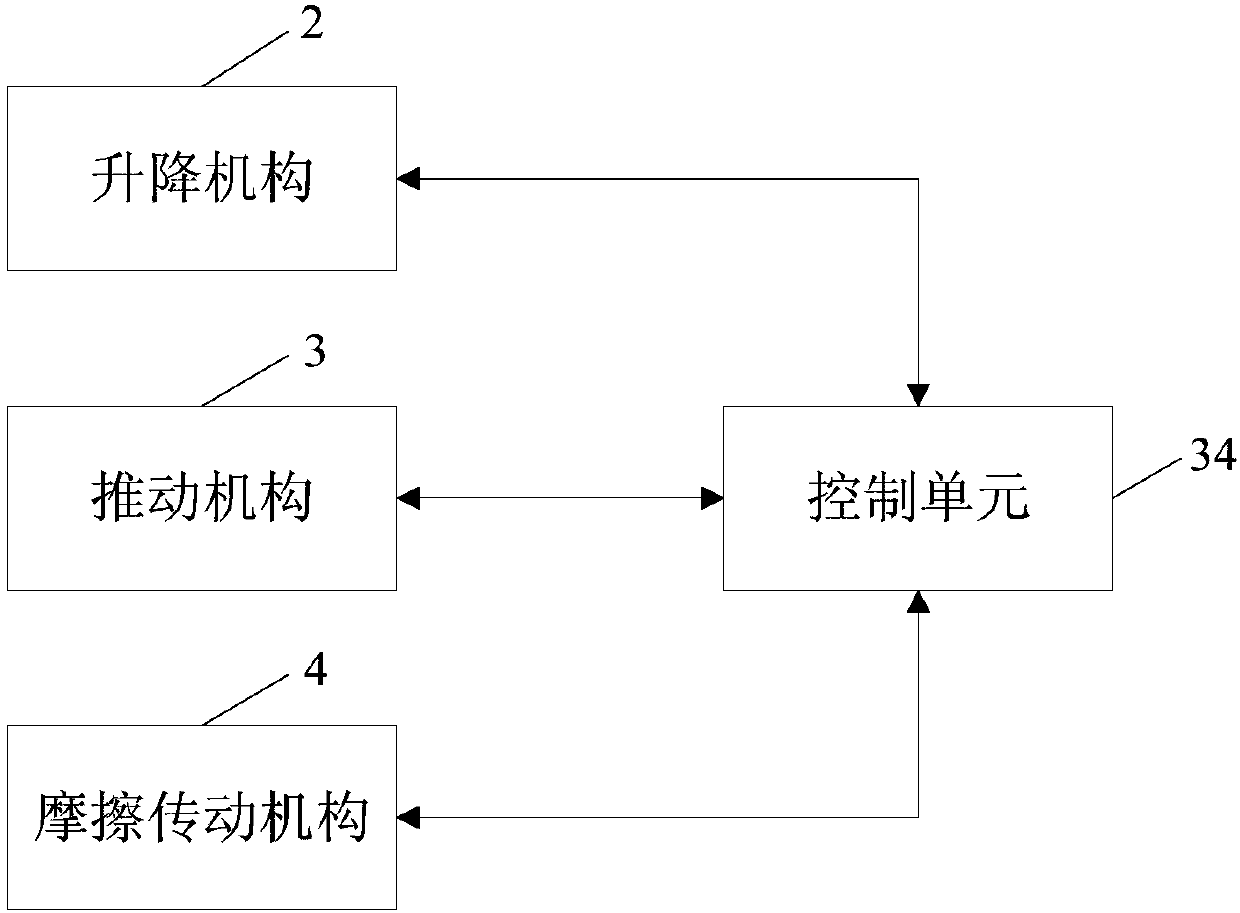

[0035] Such as Figure 1 ~ Figure 3 As shown, the flying disc projecting device of this embodiment includes a frame, a launching frame 1 , a lifting mechanism 2 , a pushing mechanism 3 and a friction transmission mechanism 4 .

[0036] The inside of the frame has an accommodating space for placing a flying disc, which can limit the displacement of the flying disc, which includes a first square frame 5, a second square frame 6 and four support columns 7, and the four support columns 7 are parallel to each other, the first square frame 5 and the second square frame 6 are arranged parallel to each other, and are pe...

Embodiment 2

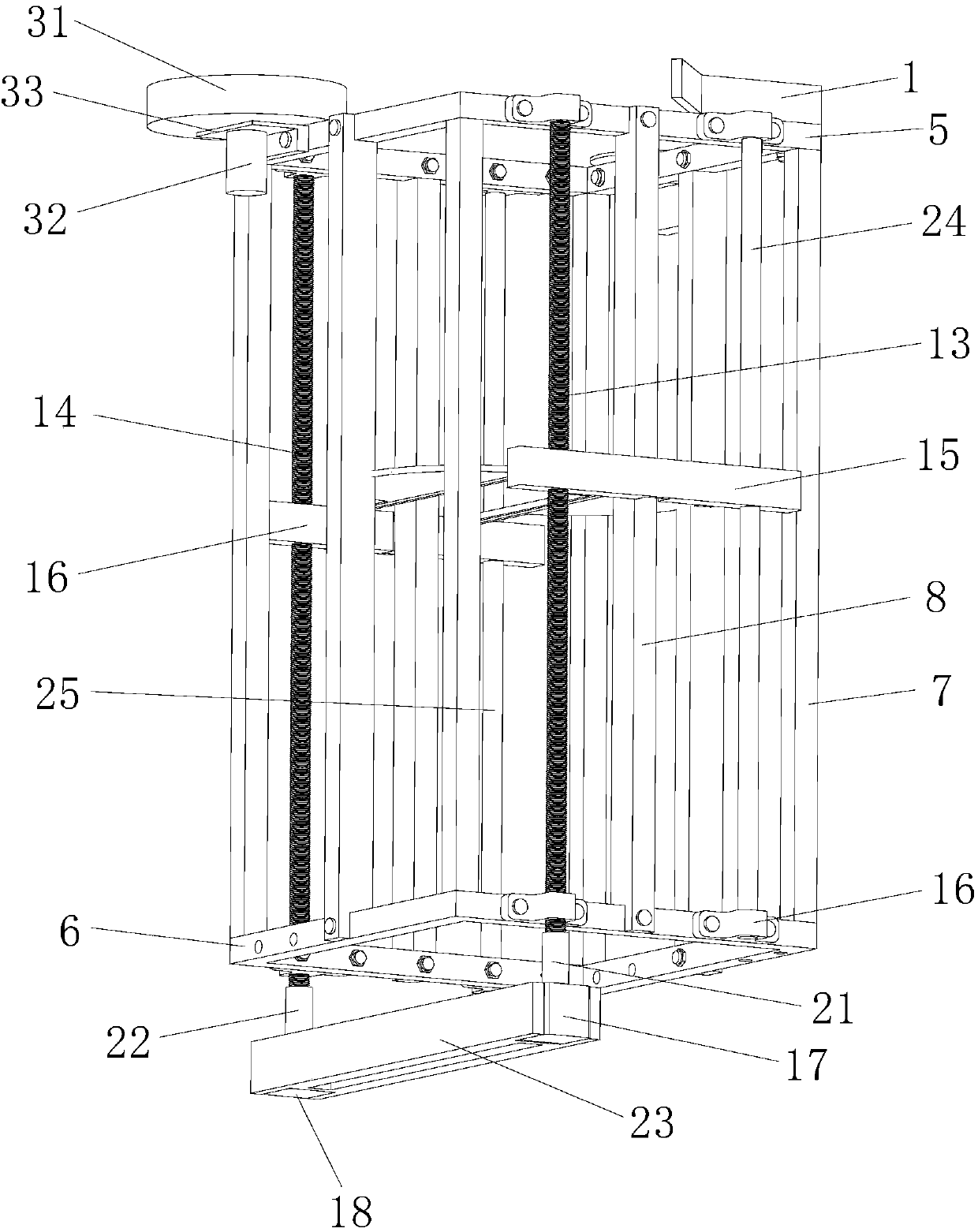

[0059] The main features of this embodiment are: the support frame, lifting screw, lifting slider and lifting motor of the lifting mechanism 2 are all one, and the lifting screw and lifting slider are arranged on the front, rear, left or right of the frame. outside of the department. All the other are with embodiment 1.

Embodiment 3

[0061] The main features of this embodiment are: the frame is not provided with a fixed mount 8, the first lifting screw rod 13 is arranged at the middle position outside the front part of the frame, and the second lifting screw rod 14 is arranged at the middle position outside the rear part of the frame, The first lifting light bar 24 is arranged on the middle position outside the left part of the frame, and the second lifting light bar 25 is arranged on the middle position outside the right part of the frame. Since the positions of the lifting screw and the lifting light bar have changed, the first lifting slide Both the block 15 and the second lifting slider 16 are arranged in a bent structure. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com