Heat exchanger and thermal management facility for batteries of electric or hybrid vehicles

A heat exchanger and heat exchange tube technology, which can be used in the arrangement of multiple different prime movers of power plants, general power plants, electric vehicles, etc., and can solve problems such as expensive, limited heat exchange efficiency, and limited heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

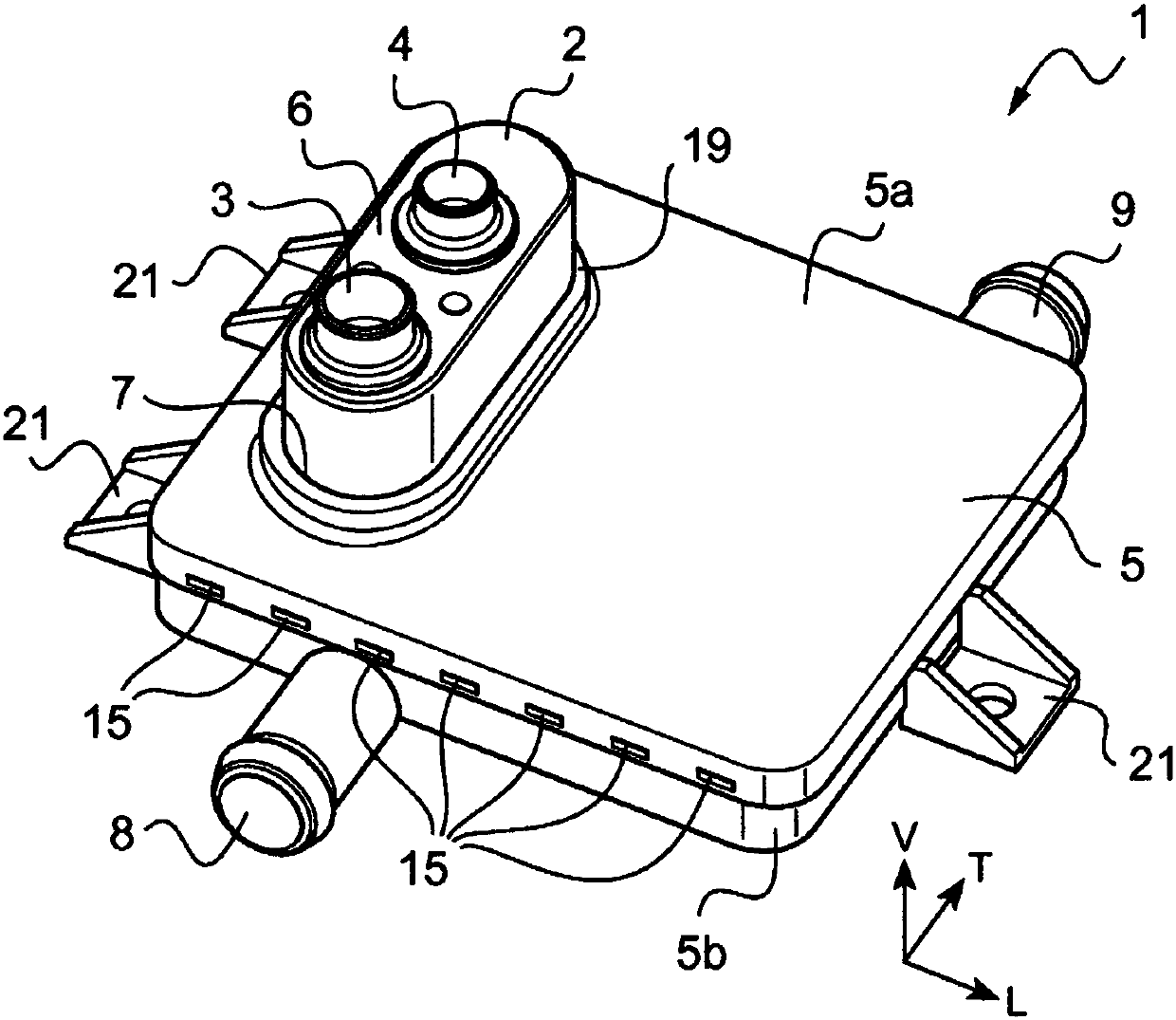

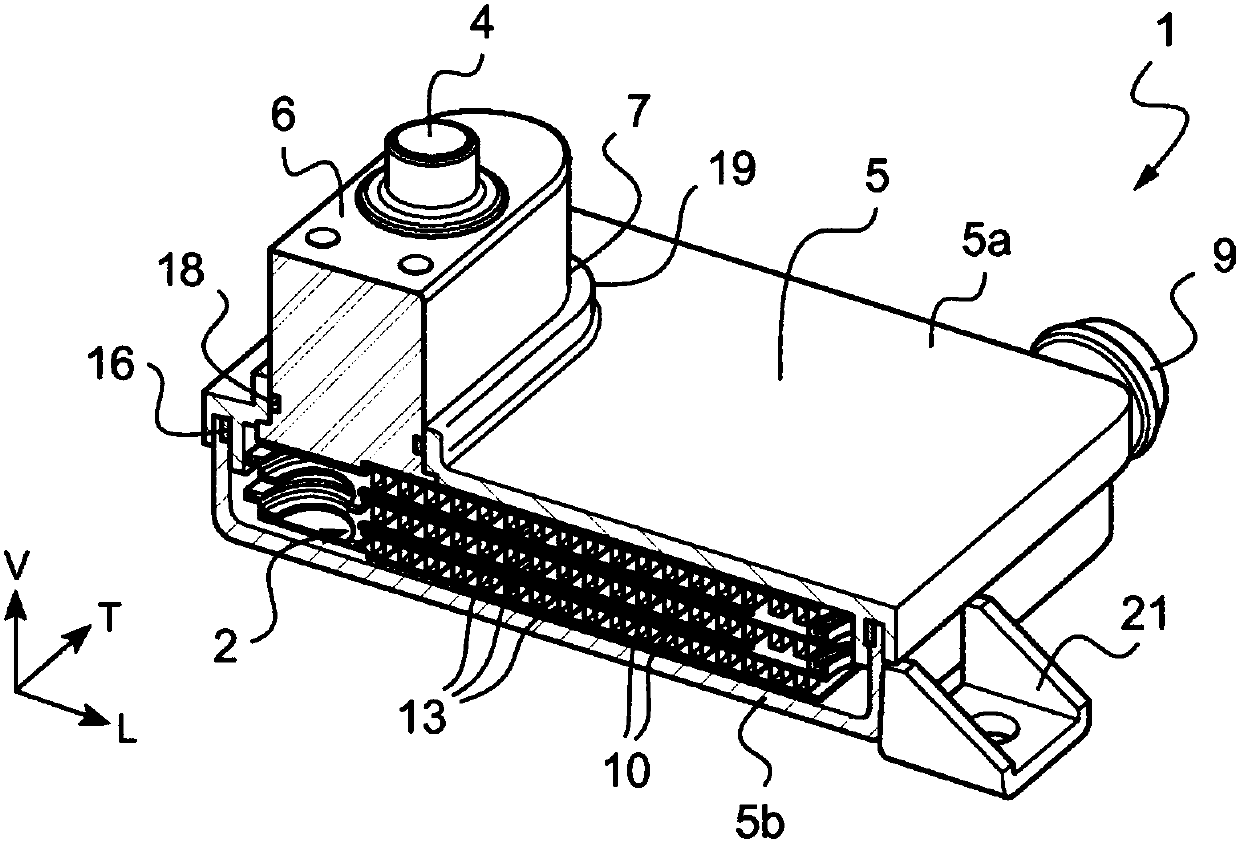

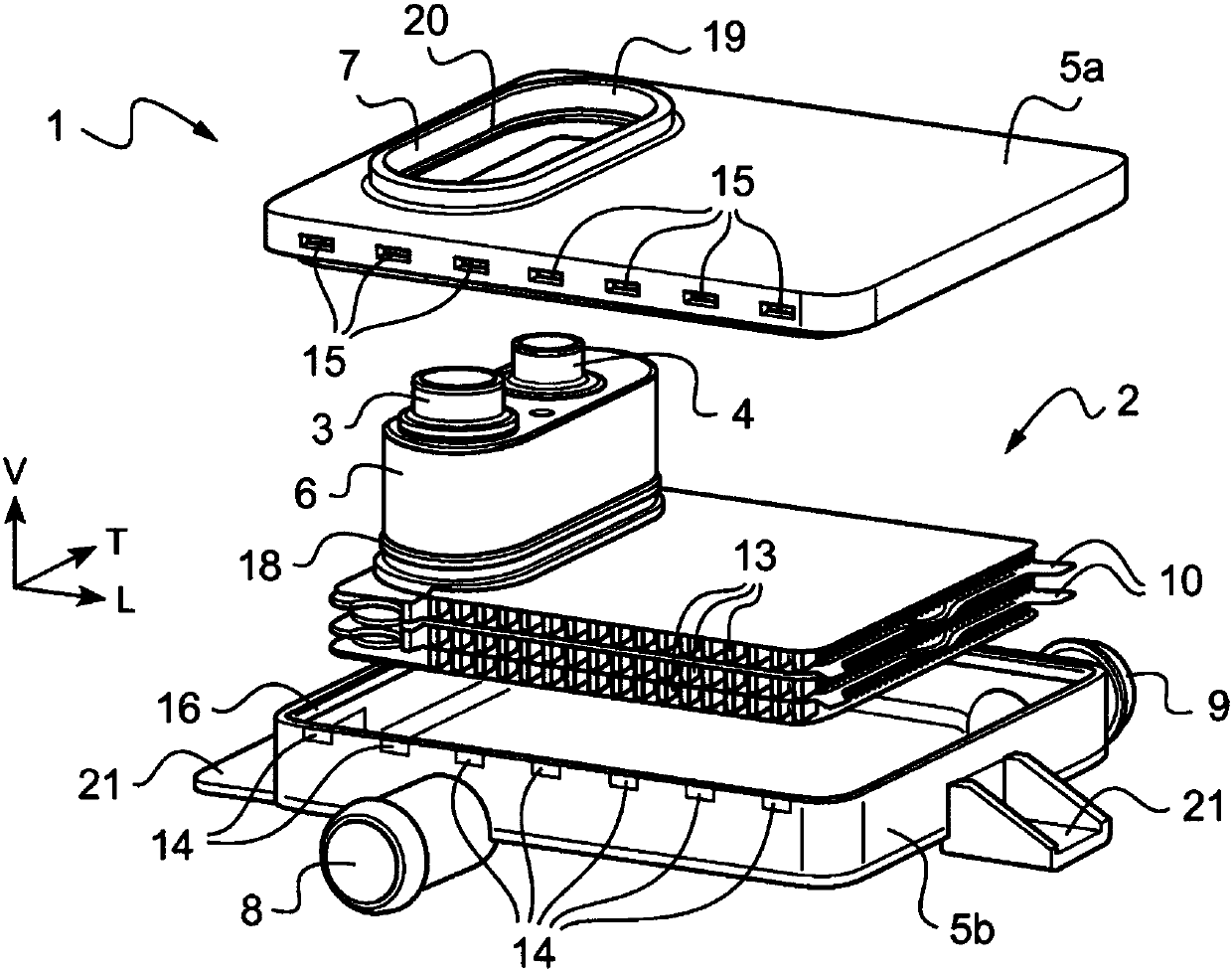

[0047] The rest of the description uses the figure 1 The longitudinal, vertical and transverse directions indicated by the axes L, V, T are fixed relative to the heat exchanger 1 , 1 ′, but do not limit the invention.

[0048] Figures 1 to 3 A first embodiment of a heat exchanger 1 is shown, which is designed, for example, to cool a battery of an electric or hybrid vehicle and remove heat from said battery.

[0049] The heat exchanger 1 comprises a circulation device 2 for a first heat transfer fluid, said circulation device 2 comprising a first heat transfer fluid inlet 3 and a first heat transfer fluid outlet 4, the first heat transfer fluid being designed to Flow between the hot fluid inlet 3 and the first heat transfer fluid outlet 4 .

[0050] The heat exchanger 1 additionally comprises a housing 5 which is made of plastic, for example.

[0051] The housing 5 is substantially hollow and forms a seat designed to receive the circulation device 2 for the first heat trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com