Installation and commissioning method of an indirect output shaft position measuring device

A measurement device, installation and debugging technology, applied in the direction of measurement devices, electric devices, instruments, etc., can solve the problem of large overall size, achieve the effect of small rotation angle, compact structure, and miniaturization design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

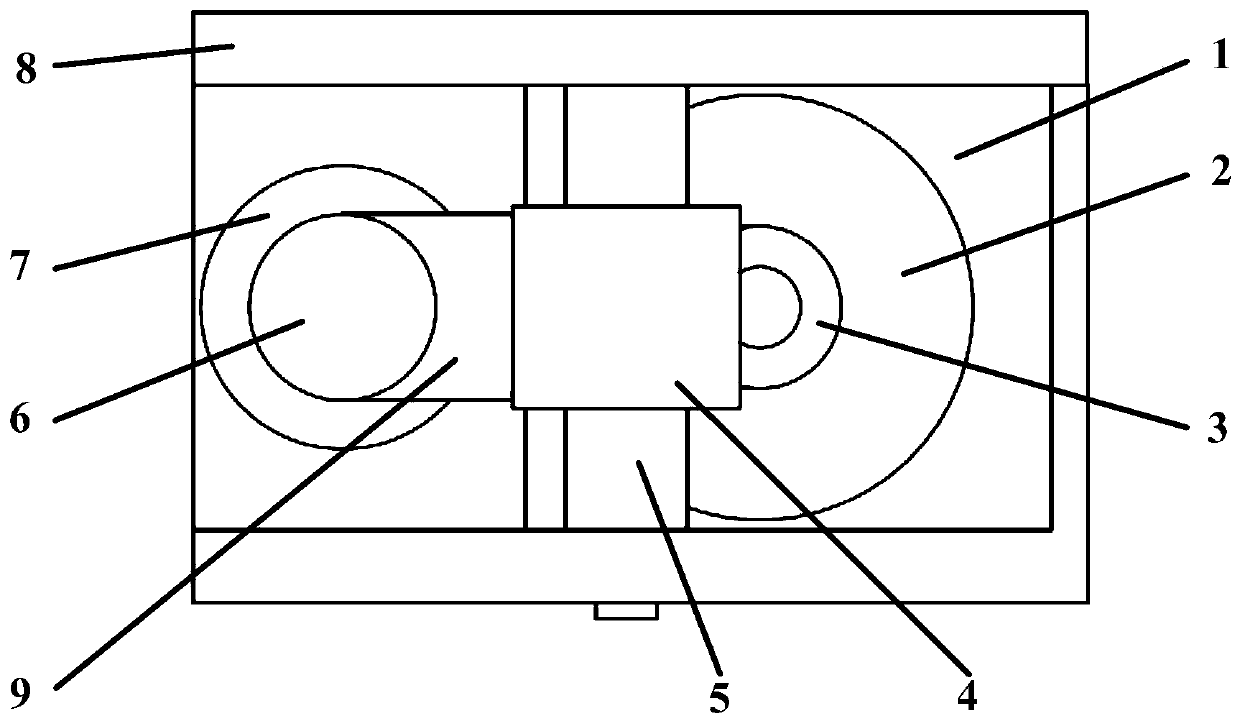

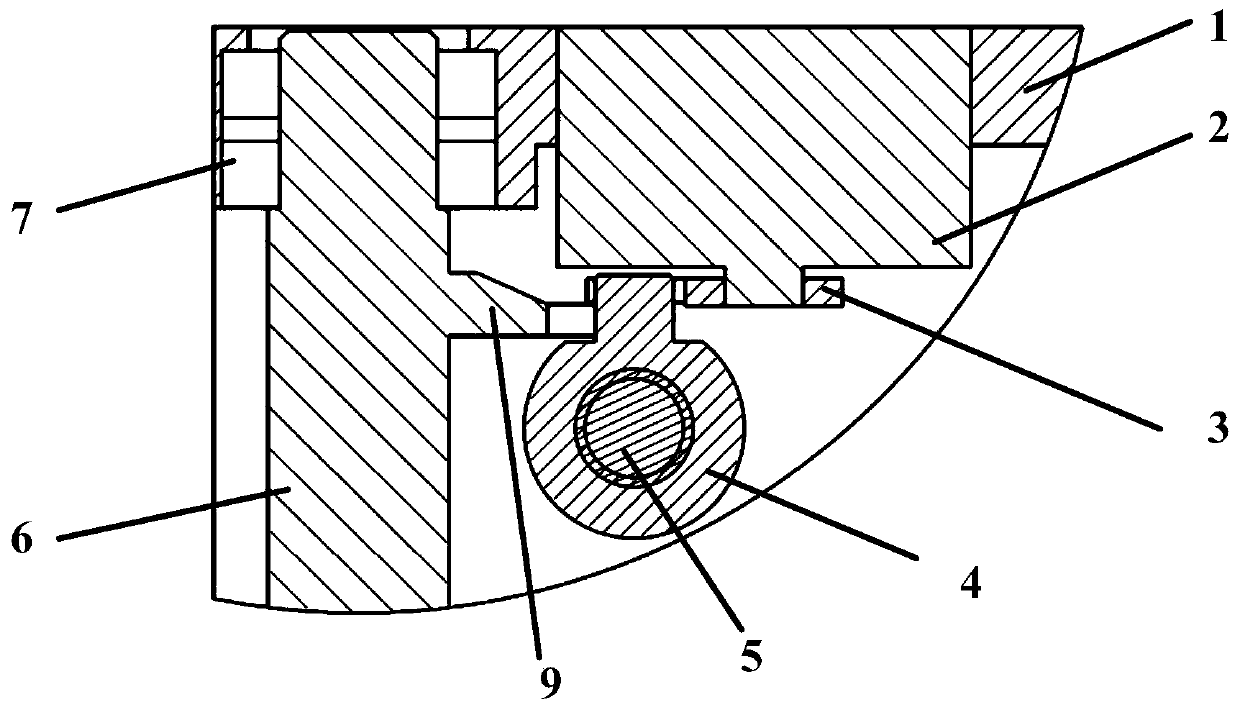

[0071] The measuring device is installed and commissioned in the following steps:

[0072] S1, install the sensor shift fork 3 on the shaft of the angular displacement sensor 2, fix the angular displacement sensor 2 on the base 1 through the mounting flange; fix the output shaft 6 on the base 1 through the bearing A 7;

[0073] S2. Rotate the sensor fork 3 and the output shaft fork 9 to align them; rotate the lead screw nut 4 to the middle of the lead screw 5 and install the lead screw 5 so that the sensor fork 3 and the output shaft fork 9 are aligned Form a sliding pair with the cylindrical boss of the lead screw nut 4;

[0074] S3. Adjust the axial position of the output shaft 6 by adjusting the bearing A 7; adjust the axial position of the angular displacement sensor 2 by adjusting the mounting flange; until the gap between the sensor fork 3 and the output shaft fork 9 0.2mm;

[0075] S4, connect the output shaft 6 and the end cover 8 through the bearing B, install and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com