Aero-engine rotor simplified equivalent test device for high-speed dynamic balance

A high-speed dynamic balance and test device technology, which is applied in the static/dynamic balance test, engine test, measuring device, etc., can solve problems that cannot be calculated theoretically and have complex structures, so as to promote research and development, simplify end-tooth connections, and reduce Calculate the effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

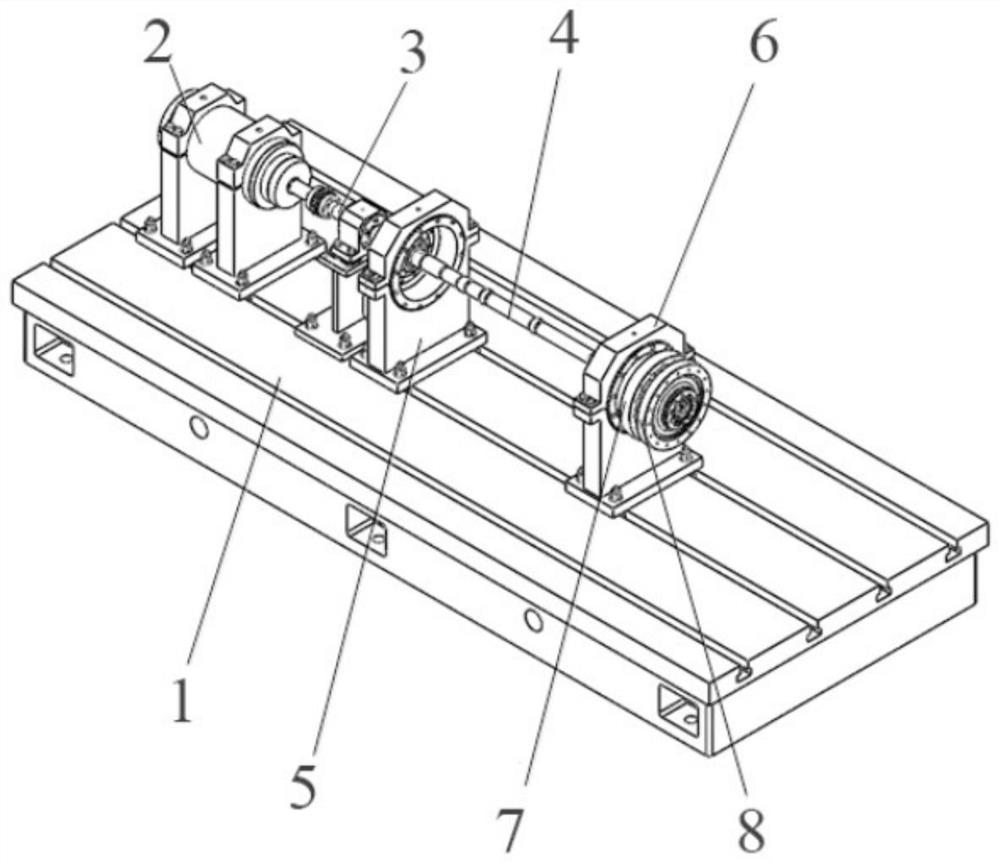

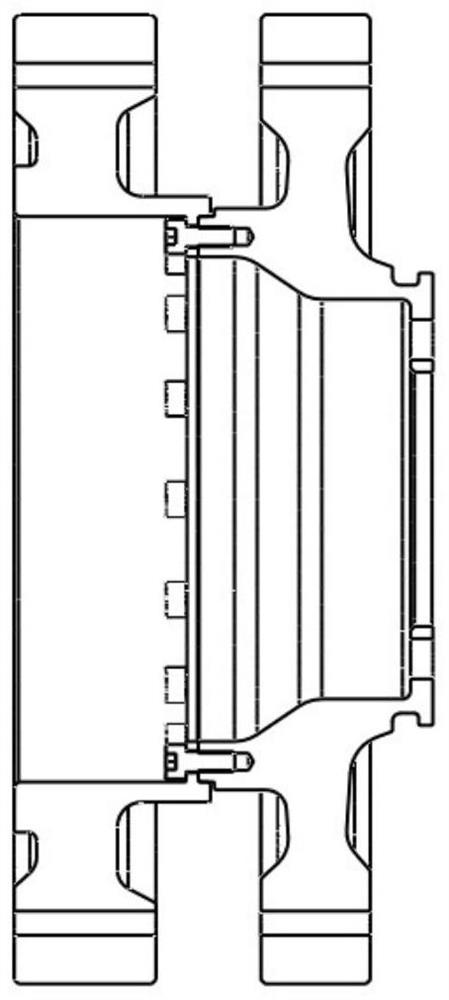

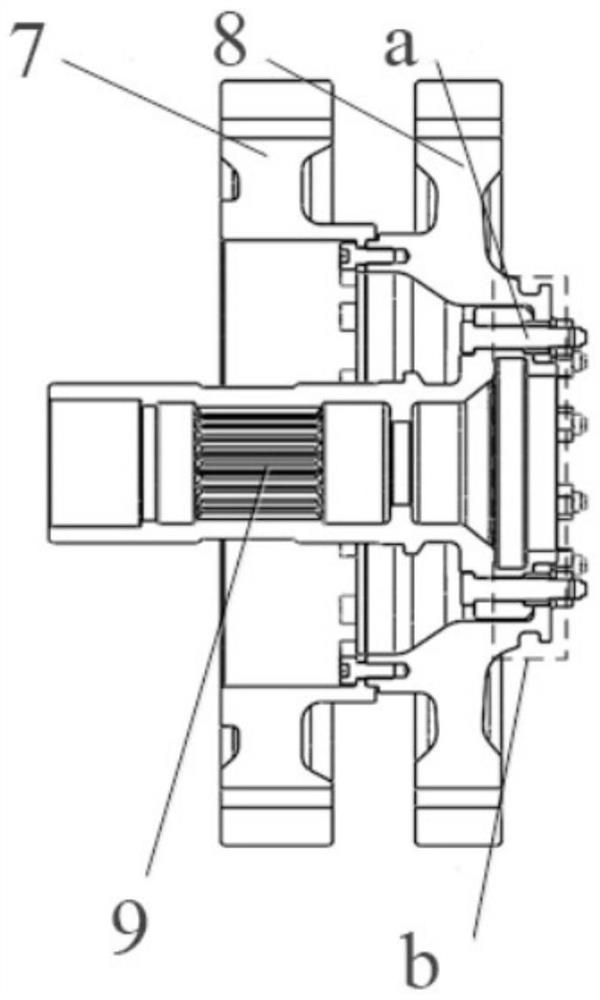

[0053] Such as figure 1 and Figure 8 As shown: This embodiment provides a simplified equivalent test device for high-speed dynamic balancing of aviation rotors, including: T-slot platform 1, high-speed motor 2, spline drive shaft 3, slender shaft 4, short Shaft 9, moving turbine disk and supporting device; the high-speed motor 2, spline drive shaft 3, elongated shaft 4, short shaft 9 and moving turbine disk are arranged on the T-slot platform 1 by means of the supporting device ;

[0054]The high-speed motor 2 is connected to one end of the elongated shaft 4 by means of the spline transmission shaft 3; the other end of the elongated shaft 4 is connected to the short shaft 9 with an interference fit c; The turbine disk is installed on the short shaft 9; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com