Production method of modified montmorillonite powder and system thereof

A technology of montmorillonite powder and production method, applied in the field of production method and system of modified montmorillonite powder, can solve the problems of high energy consumption, inability to guarantee product uniformity and stability, etc., and achieve zero emission and industrial reliability. Strong operability and continuous process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: Preparation of modified montmorillonite powder small test

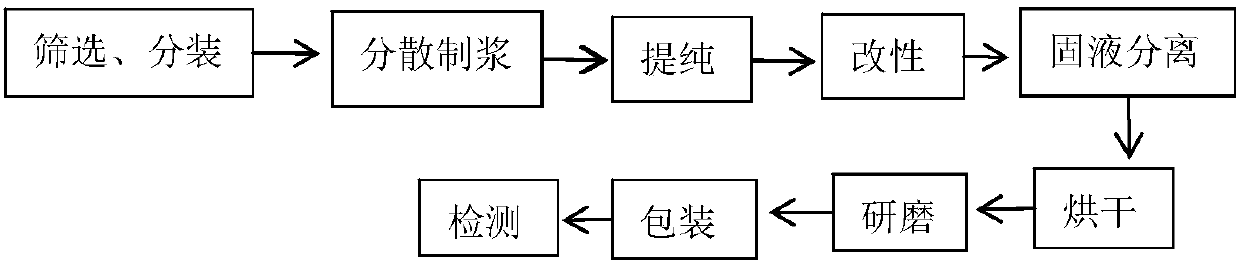

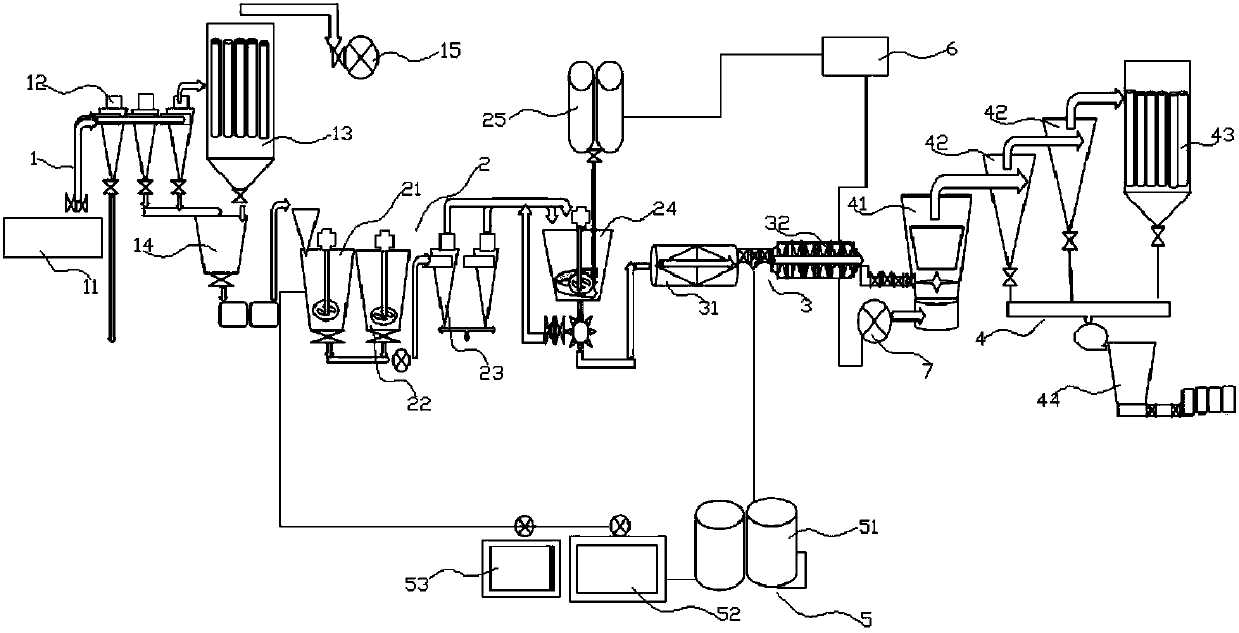

[0043] A kind of production method of modified montmorillonite powder test, specifically comprises the following steps:

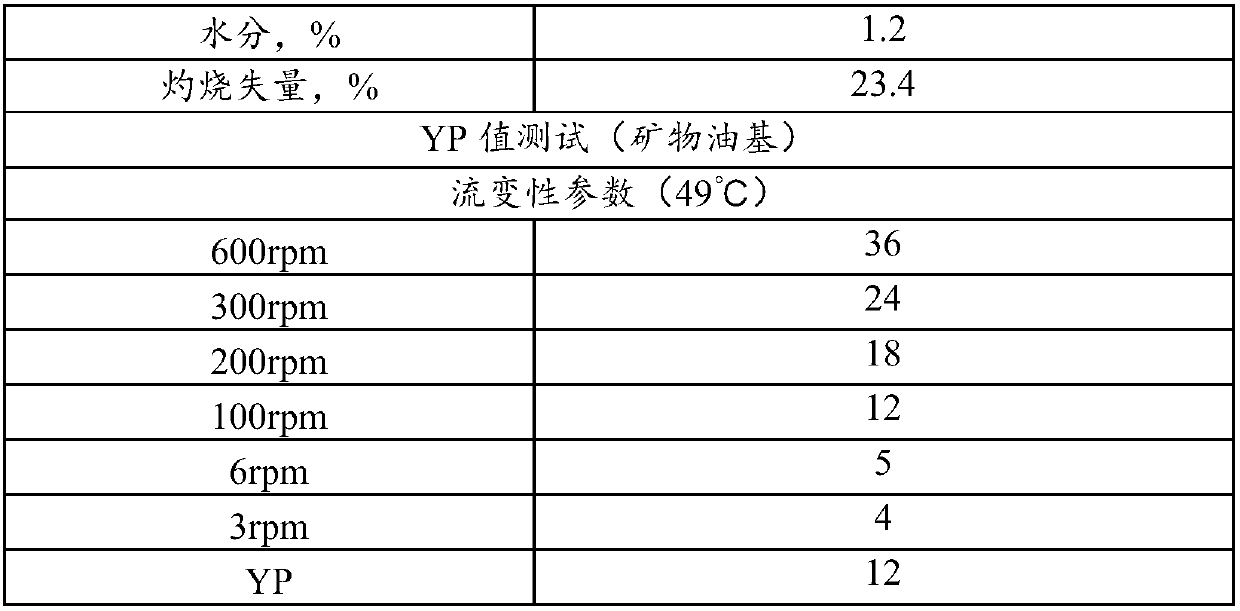

[0044] a. Mix sodium-based montmorillonite powder and deionized water according to the ratio of 1:15, disperse and make pulp, fully wet and stir for 1 hour, add anhydrous sodium carbonate according to the ratio of 1:30, and continue stirring until the mixture is uniform; at 49°C The rheological properties of the base pulp were determined to be 13, 9, 7, 5, 4, 3.5;

[0045] b. Settling the base slurry prepared in step a for 2h, centrifuging, measuring and adjusting the pH value of the base slurry to 12;

[0046] c. Shearing and stirring the base slurry prepared in step b, heating to 55°C, adding an organic cationic modifier in a proportion of 10%, heating to 9°C and continuing to stir evenly;

[0047] d. Separating and washing the base slurry prepared in step c, and then dryin...

Embodiment 2

[0059] Example 2: Pilot test for preparation of modified montmorillonite powder

[0060] A pilot production method of modified montmorillonite powder, specifically comprising the following steps:

[0061] a. Sieve the natural montmorillonite powder to remove low-grade and low-quality montmorillonite powder;

[0062] b. Mix sodium-based montmorillonite powder and deionized water according to the ratio of 1:8, disperse and make pulp, fully wet and stir for 1 hour, add anhydrous sodium carbonate according to the ratio of 1:10, and continue stirring until the mixture is uniform;

[0063] c. Settling the base slurry prepared in step b for 2h, centrifuging, measuring and adjusting the pH value of the base slurry to 12;

[0064] d. Shearing and stirring the base slurry prepared in step c, heating to 55°C, adding an organic cationic modifier in a proportion of 45%, heating to 9°C and continuing to stir evenly;

[0065] e. Separating and washing the base slurry prepared in step d, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com