Glass edge grinding device

A glass edging and vertical plate technology, which is applied in the direction of grinding/polishing safety devices, grinding machines, machine tools suitable for grinding workpiece edges, etc., can solve the problems of waste of resources, water consumption, etc., and achieve reduced emissions, simple structure, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

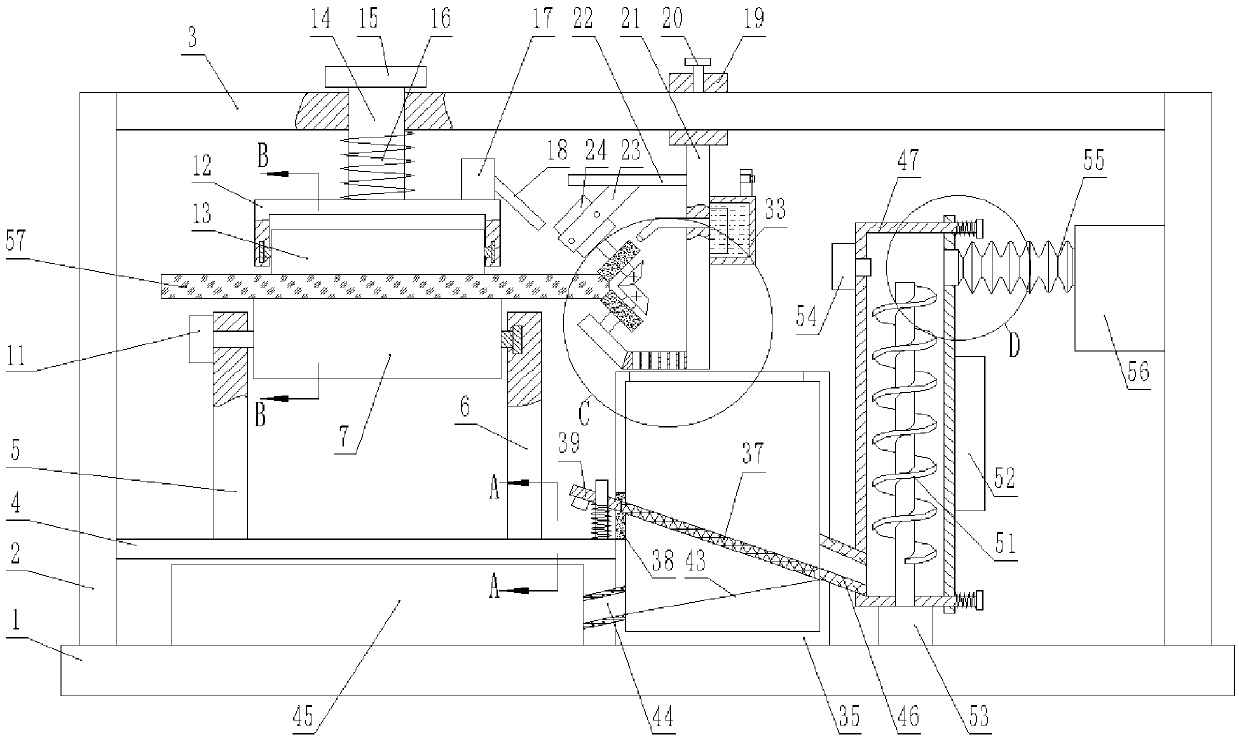

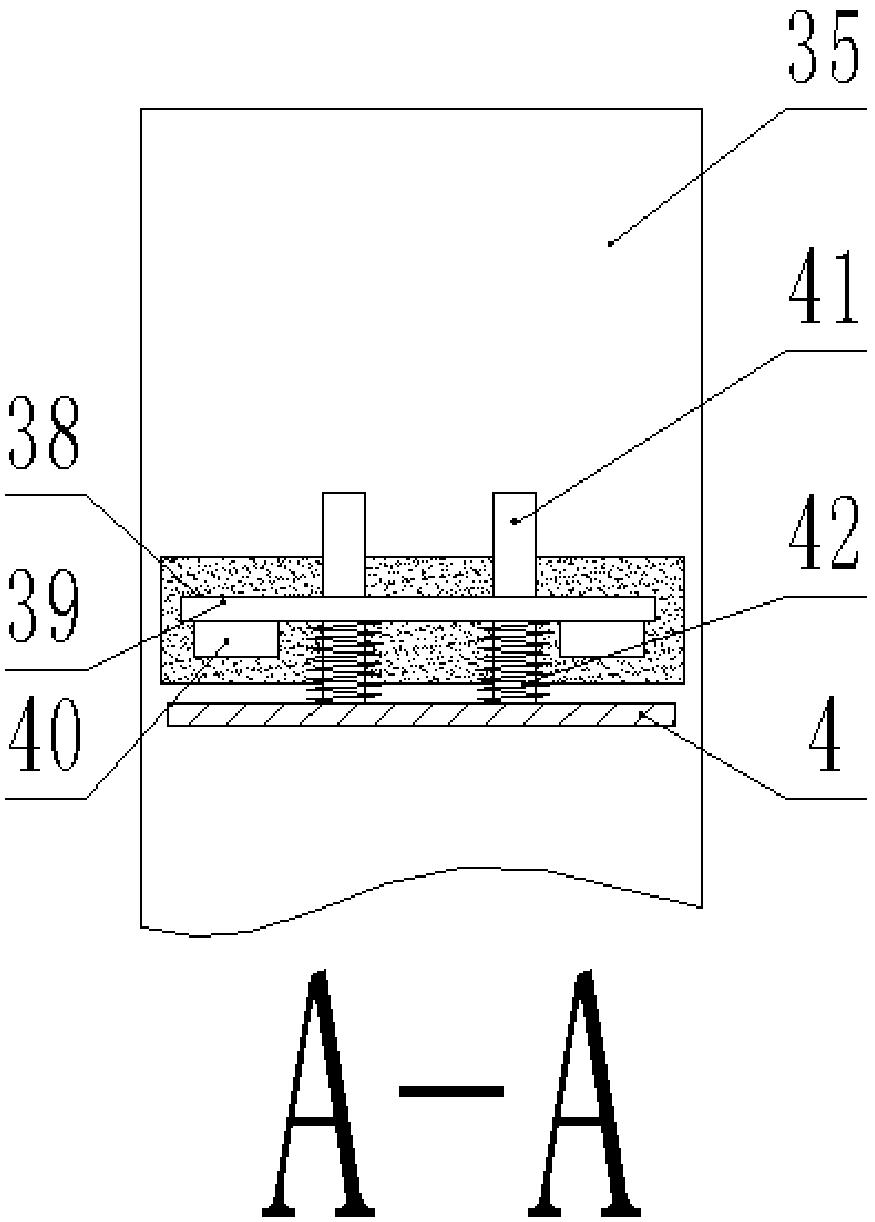

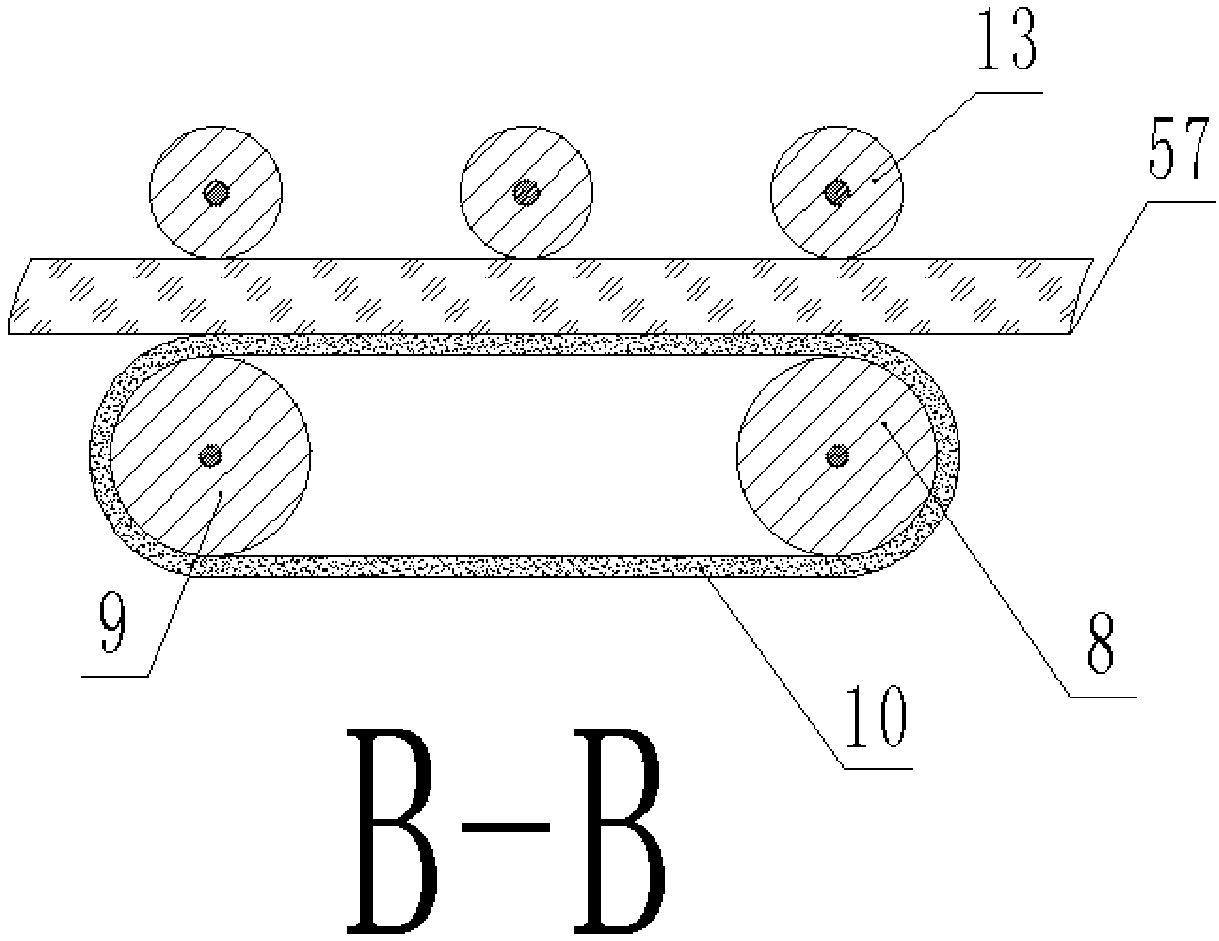

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, a glass edging device includes a base 1, the top of the base 1 is fixed with a support frame 2, the top of the support frame 2 is fixedly connected with a fixed plate A3, and one side of the support frame 2 is close to the base 1 A support plate 4 is fixedly connected, and the top of the support plate 4 is fixedly provided with a fixed vertical plate A5 and a fixed vertical plate B6, and a conveying device 7 is arranged between the fixed vertical plate A5 and the fixed vertical plate B6, and the conveying device 7 It is composed of a driving wheel 8, a driven wheel 9 and a conveyor belt 10. One side of the driving wheel 8 is rotatably connected to the fixed vertical plate B6 through a rotating rod, and the other side of the driving wheel 8 is passed through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com