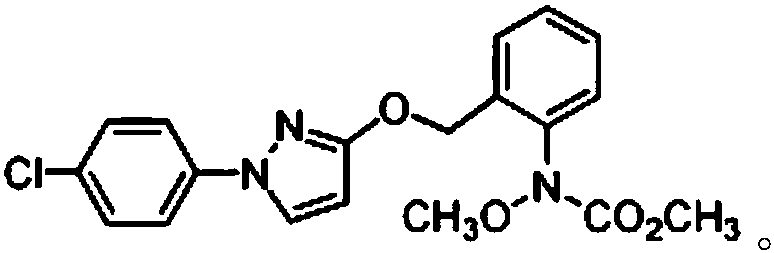

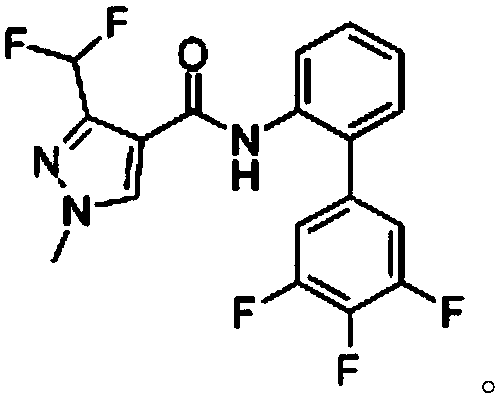

Microcapsule suspension-suspending agent containing pyraclostrobin and fluxapyroxad as well as preparation method of microcapsule suspension-suspending agent

A technology of pyraclostrobin and fluoxamid, applied in the field of pesticides, can solve the problems of disease mixing, easy generation of drug resistance, environmental pollution, etc., and achieve the effect of good lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

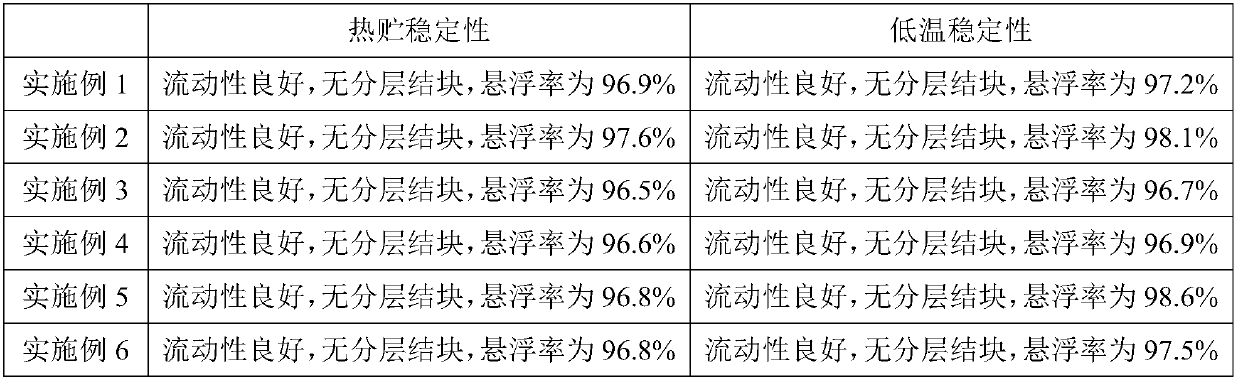

Examples

preparation example Construction

[0027] In the second aspect, the present invention provides a method for preparing a microcapsule suspension-suspension containing pyraclostrobin and flufenapyr, the preparation method may include the following steps: S1, pyraclostrobin can be dissolved in In the organic solvent, oil-soluble capsule wall material and emulsifier can be added to mix to obtain the oil phase material; the dispersant wetting agent and defoamer can be dissolved in water to obtain the water phase material; S2, the oil phase material can be mixed with The water-phase materials are mixed and sheared at 10000-13000 rpm for 1-15 minutes to obtain an O / W emulsion; S3, water-soluble capsule wall materials can be added to the O / W emulsion and can be Heat preservation reaction at 40°C-80°C for 0.5-4 hours to obtain pyraclostrobin microcapsule suspension; The pH adjuster, the antifreeze agent and water are mixed to obtain a microcapsule suspension-suspension formulation containing pyraclostrobin and flufenapy...

Embodiment 1

[0036] Example 1: Preparation of 20% pyraclostrobin·flufenapyr microcapsule suspension-suspension concentrate (pyraclostrobin 10%, flufenapyr 10%)

[0037] (1) Preparation of 20% pyraclostrobin microcapsule suspension

[0038] Dissolve 20.6 grams of pyraclostrobin (content 98%) in 30 grams of solvent naphtha No. 150, add 2 grams of aliphatic polyisocyanate and 3 grams of sorbitan polyoxyethylene ether, and stir evenly to obtain an oil phase; Dissolve 3 grams of sodium lignosulfonate and 0.2 grams of silicone defoamer in 40.7 grams of water to obtain a water phase; then add the oil phase to the water phase and shear for 1 minute at 10,000 rpm to form an O / W emulsion; 0.5 g of ethylenediamine was added dropwise to the emulsion, and the temperature was raised to 50° C. for 2 hours of heat preservation reaction to obtain 100 g of 20% pyraclostrobin microcapsule suspension.

[0039] (2) Preparation of 25% flufenapyramide suspension concentrate

[0040] 25.5 grams of flufenapyroxa...

Embodiment 2

[0043] Example 2: Preparation of 20% pyraclostrobin · flufenapyr microcapsule suspension-suspension concentrate (pyraclostrobin 10%, flufenapyr 10%)

[0044] (1) Preparation of 20% pyraclostrobin microcapsule suspension

[0045] Dissolve 20.6 grams of pyraclostrobin (content 98%) in 35 grams of solvent naphtha No. 150, add 2.5 grams of aliphatic polyisocyanate and 3 grams of sorbitan polyoxyethylene ether, and stir evenly to obtain an oil phase; Dissolve 3 grams of sodium lignosulfonate and 0.2 grams of silicone antifoaming agent in 35.2 grams of water to obtain a water phase; then add the oil phase to the water phase, and shear for 5 minutes at 12000 rpm to form an O / W emulsion; 0.5 g of ethylenediamine was added dropwise to the emulsion, and the temperature was raised to 50° C. for 2.5 hours of heat preservation reaction to obtain 100 g of 20% pyraclostrobin microcapsule suspension.

[0046] (2) Preparation of 25% flufenapyramide suspension concentrate

[0047] With embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com