Evaluation method for predicting remaining creep rupture life of supercritical unit T/P91 heat-resistant steel based on room temperature Brinell hardness

A supercritical unit, Brinell hardness technology, applied in the direction of testing material hardness, measuring device, strength characteristics, etc., can solve the problems of time-consuming and laborious, large dispersion of experimental data, difficult to measure experimental data, etc., to achieve convenient and fast Evaluate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Utilize unserviced P91 heat-resistant steel in a certain power plant to realize the method for evaluating the remaining durable life of supercritical unit T / P91 heat-resistant steel based on room temperature Brinell hardness prediction of the present invention, the specific implementation method is as follows:

[0061] (1) Specimens with different aging damage obtained by heat treatment

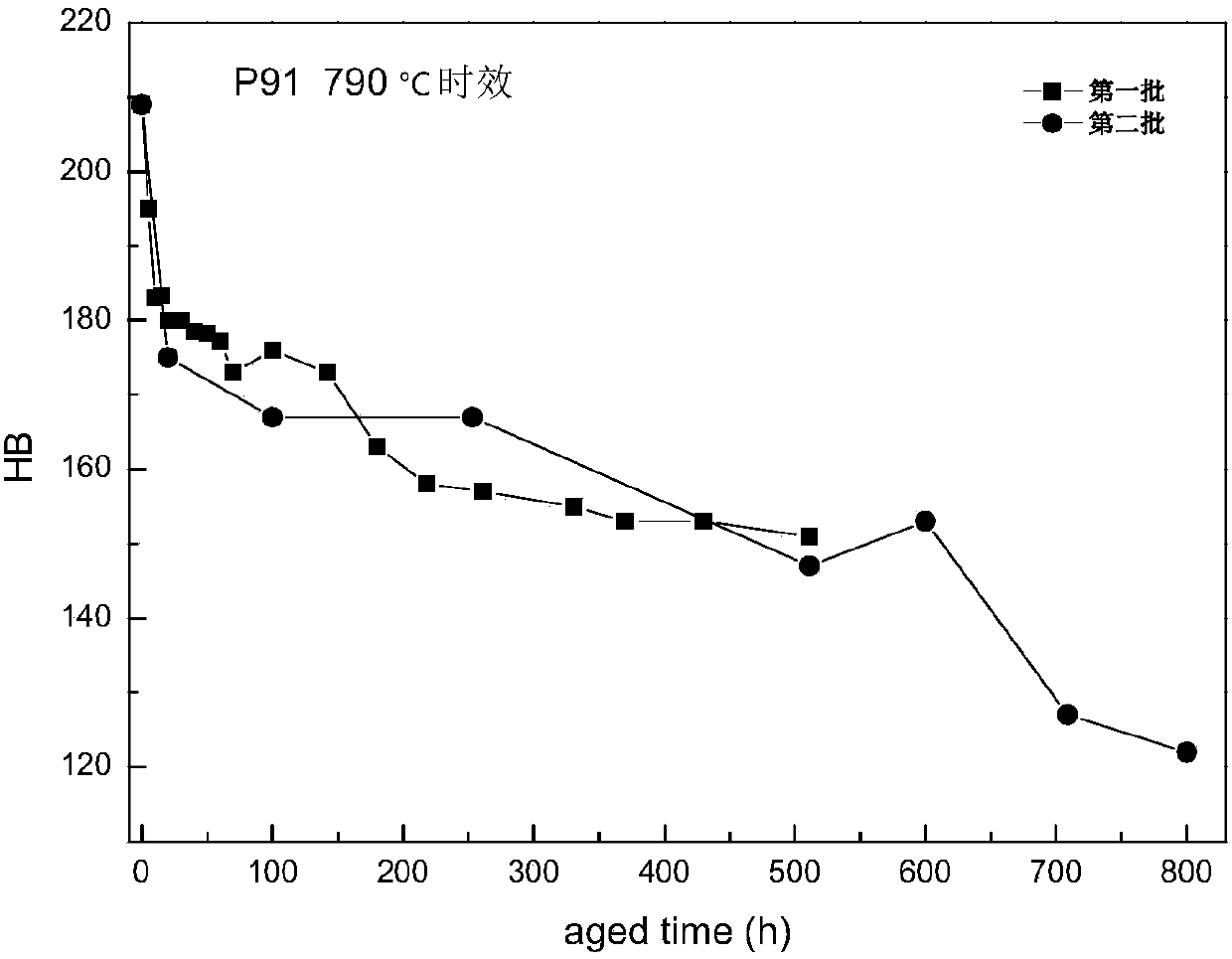

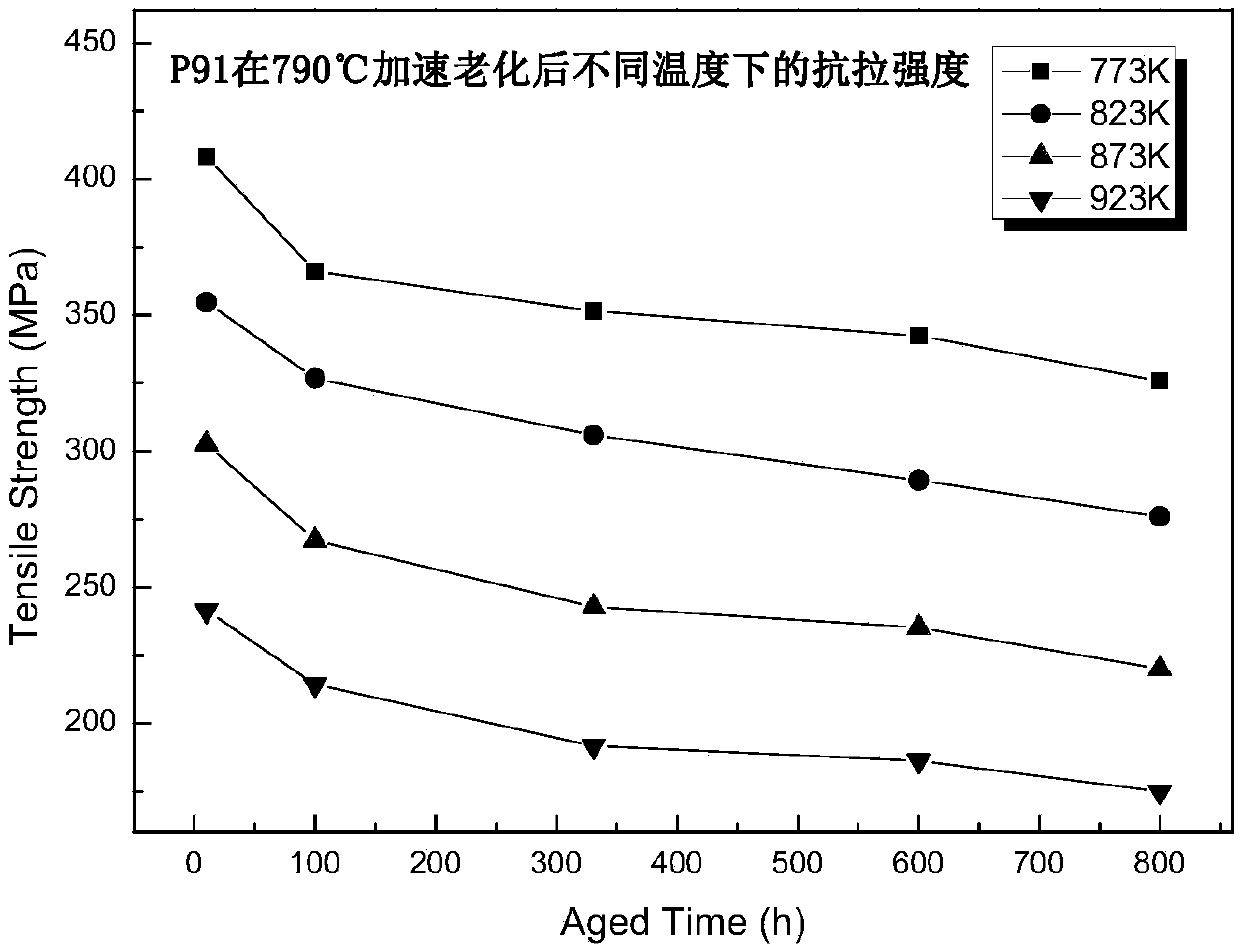

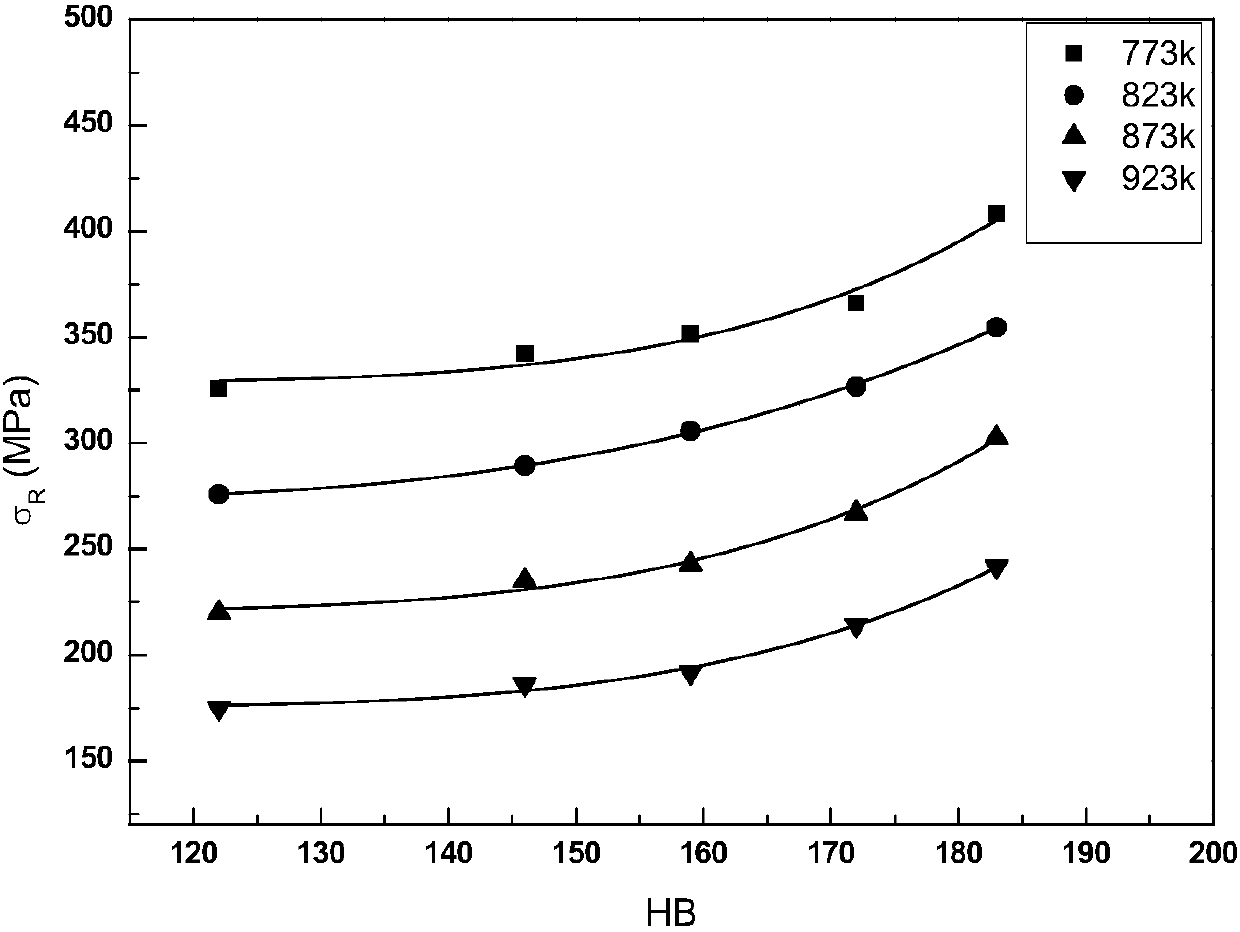

[0062] For T / P91 heat-resistant steel that has not been in service, the actual working temperature and time are used to obtain workpieces with different aging damage levels after equivalent accelerated aging heat treatment. The material is cooled to room temperature, and a part is taken to make several hardness test samples. pieces;

[0063] In this embodiment, equivalent accelerated aging aging heat treatment means: select AC 1 Aging is carried out at a temperature of 10-30°C below the temperature point, and the time is 5-800h; after aging, it is aged at 620°C to ensure the rapid pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com