Passion fruit-carambola wine, and application of same to preparation of calming and tranquillizing health products or beverages

A passion fruit and passion fruit juice technology, which is applied in the preparation of alcoholic beverages, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of insufficient utilization of nutrition and health care, difficulties in the development of passion fruit and carambola, high volatile acid, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 100

[0071] The preparation of embodiment 1 passion fruit original wine

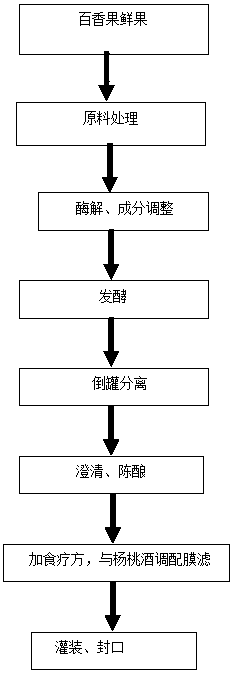

[0072] The present embodiment provides a kind of preparation method of described passion fruit original wine, comprises the steps:

[0073] S1. Raw material processing: select 80% to 90% ripe passion fruit fresh fruit, wash, cut in half, take out the pulp, remove seeds and press, filter to obtain passion fruit juice, set aside;

[0074] S2. Enzymolysis and component adjustment: add 100ppm pectinase to passion fruit juice, enzymolyze it at room temperature, add sulfur dioxide, control the sulfur dioxide content in passion fruit juice to 60ppm, adjust the sugar content to 210g / L with white sugar, and obtain passion fruit fruit juice, spare;

[0075] S3. Fermentation: Add 200 mg / L Saccharomyces cerevisiae activation solution to the passion fruit juice obtained in step S2, let it stand at room temperature for 10 minutes, inoculate it into the tank evenly, cool down to 16°C after fermentation, and ferment when th...

Embodiment 2 100

[0078] The preparation of embodiment 2 passion fruit original wine

[0079] The present embodiment provides a kind of preparation method of described passion fruit original wine, comprises the steps:

[0080] S1. Raw material processing: select 80% to 90% ripe passion fruit fresh fruit, wash, cut in half, take out the pulp, remove seeds and press, filter to obtain passion fruit juice, set aside;

[0081] S2. Enzymolysis and component adjustment: add 80ppm of pectinase to passion fruit juice, enzymolyze it at room temperature, add sulfur dioxide, control the sulfur dioxide content in passion fruit juice to 40ppm, adjust the sugar content to 180g / L with white sugar, and obtain passion fruit fruit juice, spare;

[0082] S3. Fermentation: Add 180mg / L Saccharomyces cerevisiae activation solution to the passion fruit juice obtained in step S2, let it stand at room temperature for 5 minutes, inoculate it evenly into the tank, and cool down to 14°C for fermentation after fermentation...

Embodiment 3 100

[0085] The preparation of embodiment 3 passion fruit original wine

[0086] The present embodiment provides a kind of preparation method of described passion fruit original wine, comprises the steps:

[0087] S1. Raw material processing: select 80% to 90% ripe passion fruit fresh fruit, wash, cut in half, take out the pulp, remove seeds and press, filter to obtain passion fruit juice, set aside;

[0088] S2. Enzymolysis and composition adjustment: add 120ppm pectinase to passion fruit juice, enzymolyze it at room temperature, add sulfur dioxide, control the content of sulfur dioxide in passion fruit juice to 60ppm, adjust the sugar content to 220g / L with white sugar, and obtain passion fruit fruit juice, spare;

[0089] S3. Fermentation: Add 240 mg / L Saccharomyces cerevisiae activation solution to the passion fruit juice obtained in step S2, let it stand at room temperature for 20 minutes, inoculate it evenly into the tank, and cool down to 18°C for fermentation after ferme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com