Screen plate cleaning solution and use method thereof

A technology of cleaning solution and screen plate, applied in the field of cleaning solution, can solve the problems of photosensitive emulsion 2 residue and easy residual photosensitive emulsion 2, etc., and achieve the effect of improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

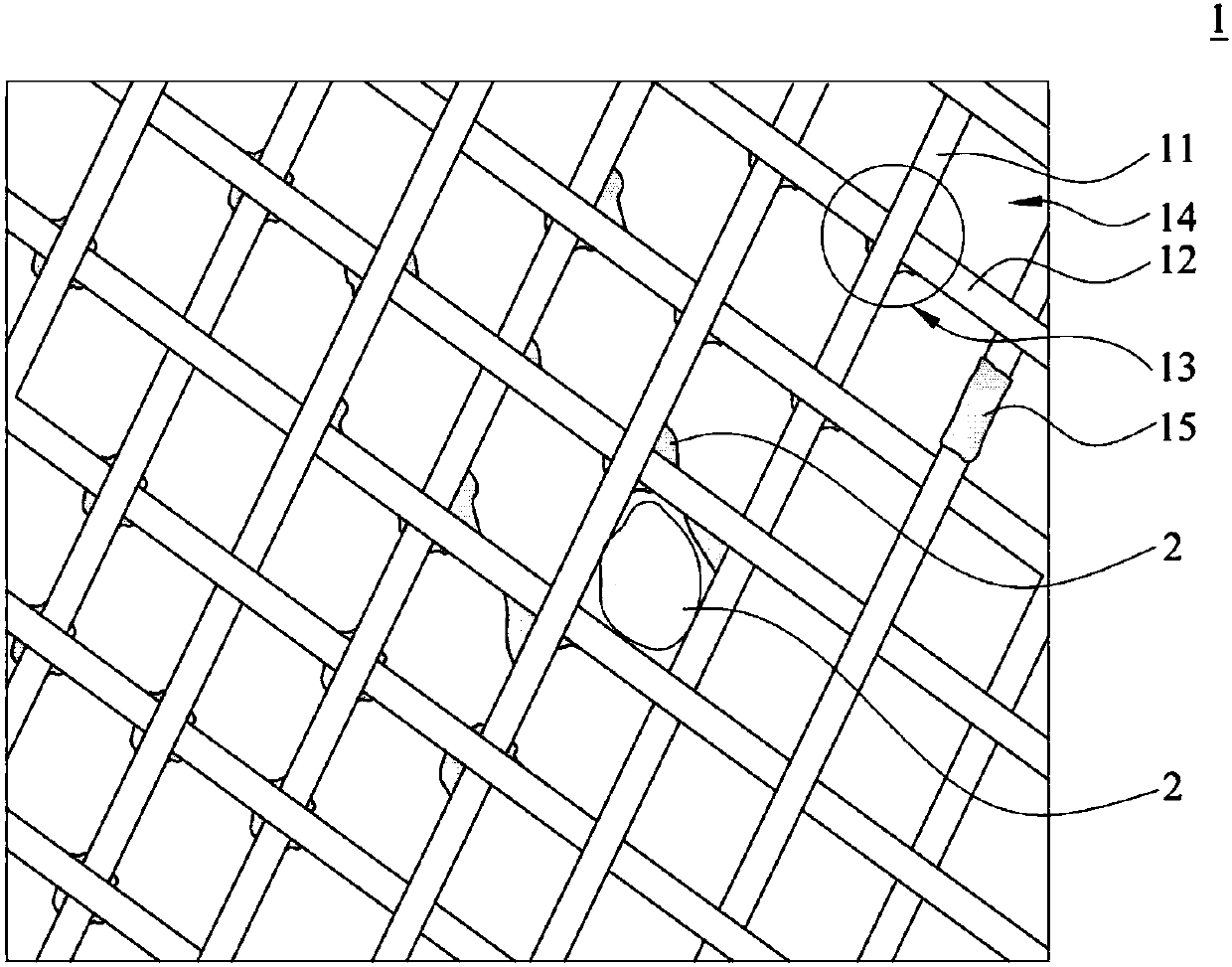

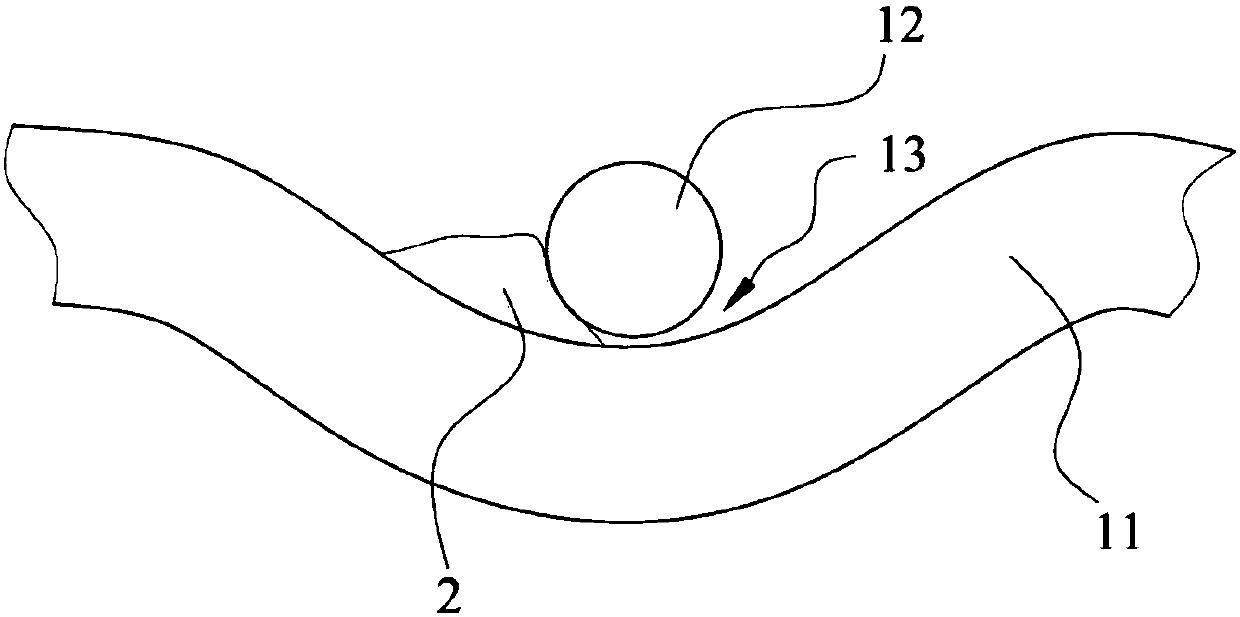

[0027] The implementation of the present invention will be described below with reference to specific specific examples and drawings. Those skilled in the art can easily understand the advantages and effects of the present invention from the content disclosed in this specification. It is worth noting that, in order to clearly demonstrate the main features of the present invention, the first figure only schematically shows the relative relationship between the main components, and is not drawn according to the actual size, so the thickness, size and shape of the main components in the figure are , arrangement, configuration, etc. are for reference only, and are not intended to limit the scope of the present invention.

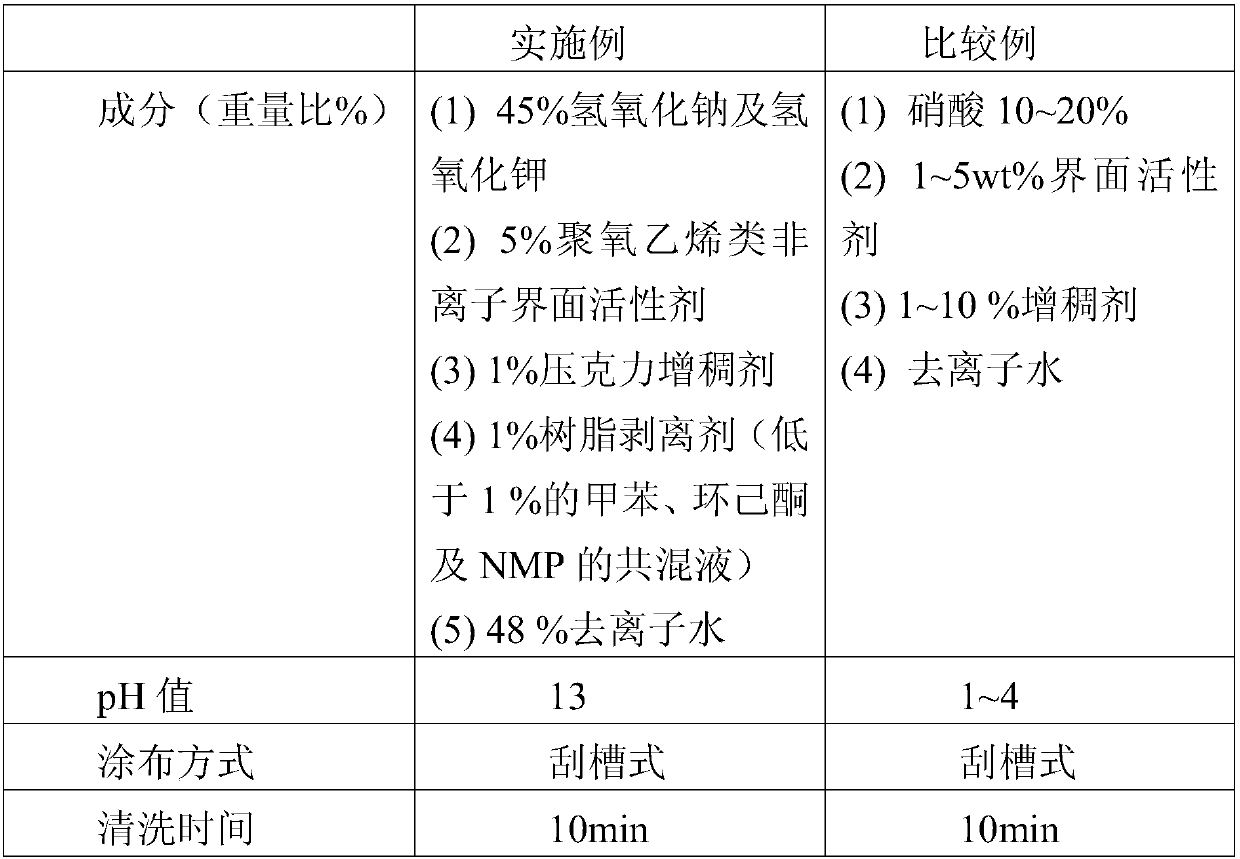

[0028] A screen cleaning liquid, comprising: basic compound and resin stripper, basic compound can be selected from alkali metal hydroxide, alkaline earth metal hydroxide, ammonium hydroxide or its combination, for example: sodium hydroxide (NaOH ), potassium hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com