Anti-fogging self-cleaning weakening ultraviolet glass coating and preparation method thereof

A glass coating and self-cleaning technology, applied in antifouling/underwater coatings, polyether coatings, radiation-absorbing coatings, etc., can solve the problems of increasing driving hazards, reducing glass transmittance, and increasing cleaning costs, etc., to achieve Excellent anti-fog performance, good self-cleaning ability and bactericidal ability, long anti-fog time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An anti-fog self-cleaning and weakening ultraviolet glass coating, the coating comprises the following components and content by weight: the coating comprises the following components and content by weight: 0.7 parts of emulsifier, 0.8 parts of polyvinyl alcohol, 0.8 parts of anionic surfactant , 1 part of photocatalyst, 1 part of sodium metasilicate, 10 parts of isopropanol, 5 parts of glycerin, 0.1 part of essence, 40 parts of ethanol and 40.6 parts of water, wherein the emulsifier is octylphenol polyoxyethylene ether, anion The surfactant is sodium polyacrylate, and the photocatalyst is g-C 3 N 4 / BiOIO 3 catalyst of light.

[0027] When the paint is prepared, after mixing the components, the mixture is stirred under a magnetic stirrer for half an hour.

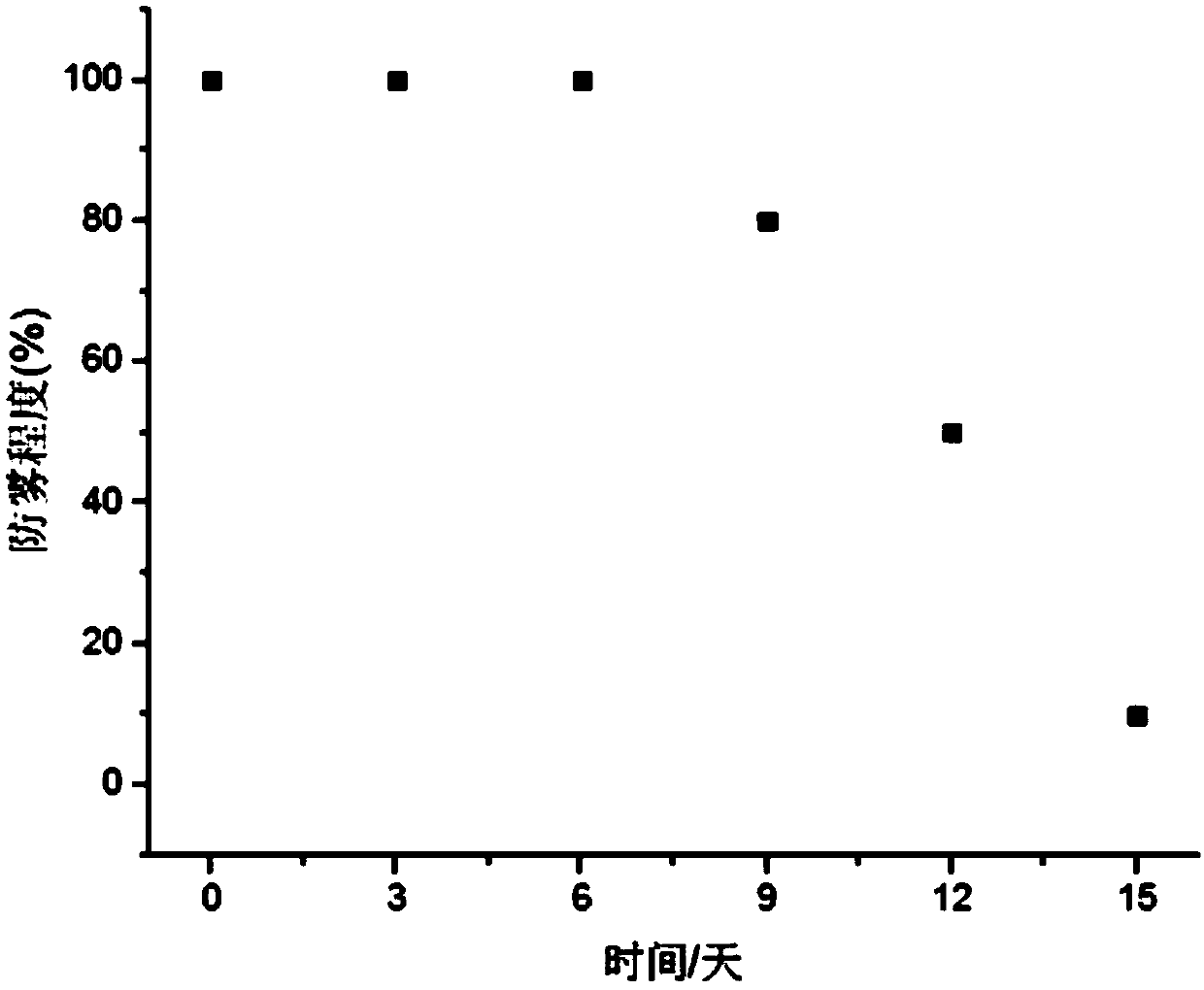

[0028] The paint was used for car windshield, bathroom vanity mirror, home glass, and glass vanity mirror respectively. The anti-fog test was carried out according to the SKFI anti-fog performance test method. Th...

Embodiment 2

[0035] An anti-fog self-cleaning and weakening ultraviolet glass coating, the coating comprises the following components and content in parts by weight: 0.1 parts of emulsifier, 1.5 parts of polyvinyl alcohol, 0.2 parts of anionic surfactant, 1.3 parts of photocatalyst, 0.1 parts of sodium metasilicate 15 parts of isopropanol, 3 parts of glycerin, 0.3 parts of essence, 30 parts of ethanol and 70 parts of water.

[0036] Among them, the emulsifier is octylphenol polyoxyethylene ether; the anionic surfactant is sodium polyacrylate; the photocatalyst is g-C 3 N 4 / BiOIO 3 Photocatalyst; essence is clove oil.

[0037] g-C 3 N 4 / BiOIO 3 The photocatalyst consists of g-C 3 N 4 , Bi(NO 3 )·5H 2 O and KIO3 Prepared by hydrothermal reaction. g-C 3 N 4 / BiOIO 3 The preparation process of the photocatalyst is as follows: the g-C 3 N 4 , Bi(NO 3 )·5H 2 O and KIO 3 Add it into water at a molar ratio of 4:1:1.2, stir it magnetically for half an hour, then add it into an a...

Embodiment 3

[0040] An anti-fog self-cleaning and weakening ultraviolet glass coating, the coating comprises the following components and content in parts by weight: 1.5 parts of emulsifier, 0.1 part of polyvinyl alcohol, 1.3 parts of anionic surfactant, 0.1 part of photocatalyst, 1 part of sodium metasilicate 1 part, 1 part of isopropanol, 8 parts of glycerin, 0.05 parts of essence, 50 parts of ethanol and 20 parts of water.

[0041] Among them, the emulsifier is octylphenyl polyoxyethylene ether; the anionic surfactant is sodium polyacrylate; the photocatalyst is g-C 3 N 4 / BiOIO 3 Photocatalyst; essence is jasmine oil.

[0042] g-C 3 N 4 / BiOIO 3 The photocatalyst consists of g-C 3 N 4 , Bi(NO 3 )·5H 2 O and KIO 3 Prepared by hydrothermal reaction. g-C 3 N 4 / BiOIO 3 The preparation process of the photocatalyst is as follows: the g-C 3 N 4 , Bi(NO 3 )·5H 2 O and KIO 3 Add it into water at a molar ratio of 6:1:0.8, stir evenly, and react at 150°C for 10 hours, then coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com