Nitrile butadiene rubber anti-aging type plasticizer preparation method

A technology of rubber anti-aging agent and nitrile rubber, which is applied in the field of preparation of nitrile rubber plasticizers, and can solve the problems of no anti-aging effect and easy precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

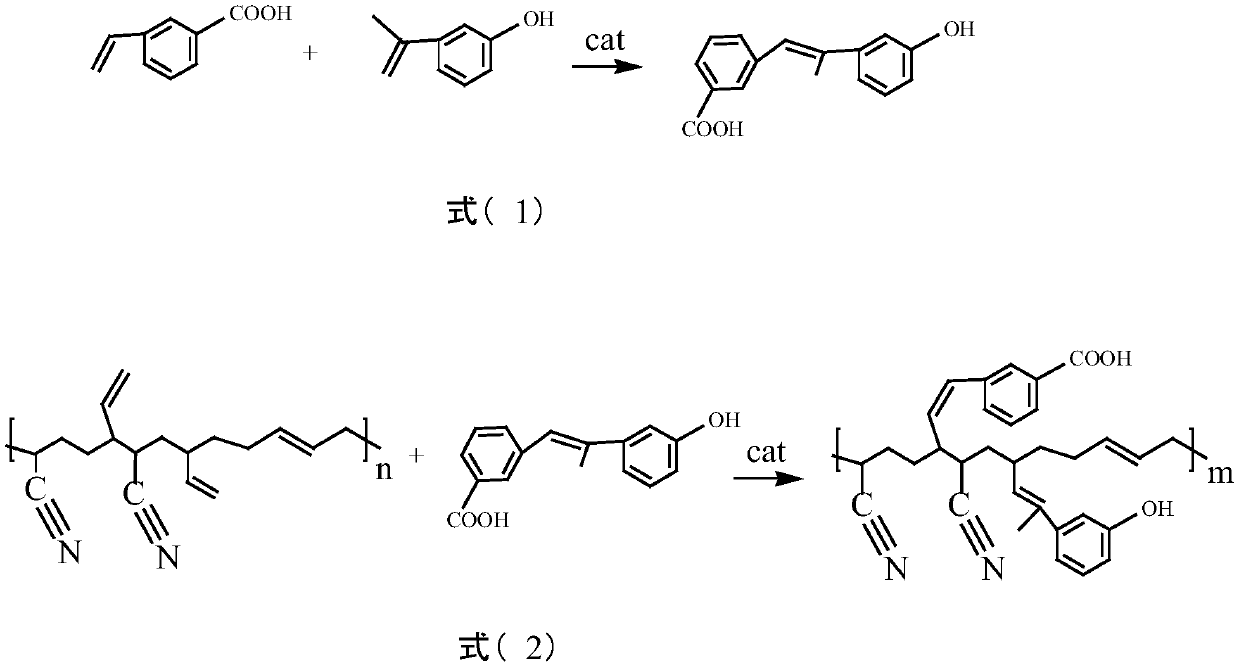

Method used

Image

Examples

Embodiment 1

[0035] Mix anti-scorch agent 2-vinylbenzoic acid and anti-aging agent 2-cyanopropenylphenol with a molar ratio of 1.0:5.0, prepare a solution with 30% mass concentration with hexane solvent, add anti-scorch agent and 0.1% olefin metathesis catalyst on the total substance amount of antiaging agent Isolate air and water, react at room temperature for 8 hours, and use a vacuum desolventizer to remove the solvent to prepare anti-scorch rubber antioxidant 1-1.

[0036] Dissolving nitrile rubber NBR3305 in acetone solvent to prepare a 0.14% concentration solution, based on 100 parts by mass of rubber, adding a mass ratio of 0.81 parts of olefin metathesis catalyst and 16 parts of anti-scorch rubber anti-aging agent 1-1, separated from air and water at 15°C, and reacted for 0.5 hours. After the reaction, the glue solution was removed by solvent to obtain an anti-aging plasticizer product with Mn of 5500.

[0037] Add 10 parts of the anti-aging plasticizer to 100 parts of nitrile ru...

Embodiment 2

[0042] Mix anti-scorch agent 3-vinyl phthalic acid and anti-aging agent 2,4,6-triallyl phenol at a molar ratio of 1.0:0.1, prepare a solution with 1% mass concentration with hexane solvent, add to the solution Add 0.01% of the olefin metathesis catalyst accounting for the total amount of anti-scorch agent and anti-aging agent After isolating air and water and reacting at room temperature for 0.5 h, the solvent was removed by a vacuum desolventizer to obtain anti-scorch rubber antioxidant 2-1.

[0043] The nitrile rubber NBR3305 is dissolved in the chloroform solvent and is formulated into a 10% concentration solution, based on 100 parts by mass of rubber, adding a mass ratio of 1.1 parts of olefin metathesis catalyst and 50.2 parts of anti-scorch rubber anti-aging agent 2-1, at 50 ℃ isolated from air and water, react for 5 hours, the reacted glue solution is detached by solvent, and an anti-aging plasticizer product with Mn of 3000 is obtained.

[0044] 10 parts of this pla...

Embodiment 3

[0050] Mix anti-scorch agent 3-vinyl phthalic acid and anti-aging agent 2,6-diallyl-p-cresol at a molar ratio of 1.0:4.0, prepare a solution with 10% mass concentration with hexane solvent, and add it to the solution Add 0.09% of the olefin metathesis catalyst accounting for the total amount of anti-scorch agent and anti-aging agent Isolate air and water, react at room temperature for 4.5 hours, and use a vacuum desolventizer to remove the solvent to obtain anti-scorch rubber antioxidant 3-1.

[0051] Dissolve nitrile rubber NBR2907 base rubber in methyl ethyl ketone solvent to prepare a 2.5% concentration solution, based on 100 parts by mass of rubber, add a mass ratio of 1.4 parts of olefin metathesis catalyst And 25.9 parts of anti-scorch rubber anti-aging agent 3-1, at 25.1 ℃ isolated from air and water, react for 2.57 hours, the reacted glue solution is removed by solvent, and an anti-aging plasticizer product with Mn of 590 is obtained.

[0052] 30 parts of this plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com