Easily-processed and reinforced nitrile butadiene rubber and preparation method thereof

An easy-to-process technology for nitrile rubber, which is applied in the field of nitrile rubber and its preparation, and can solve the problems of no reinforcement effect and easy precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

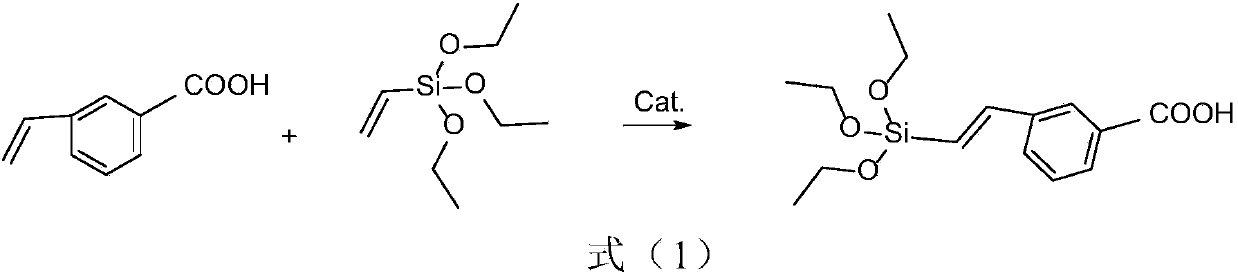

[0040] Mix anti-scorch agent 2-vinyl benzoic acid and reinforcing agent nitrile vinyl triethoxysilane at a molar ratio of 1.0:5.0, prepare a solution with a mass concentration of 30% with hexane solvent, and add anti-scorch to the solution Olefin metathesis catalysts at 0.1% of the total amount of coking agent and reinforcing agent Air and water were isolated, and after reacting at room temperature for 8 hours, the solvent was removed by a vacuum desolventizer to obtain anti-scorch rubber reinforcing agent 1-1.

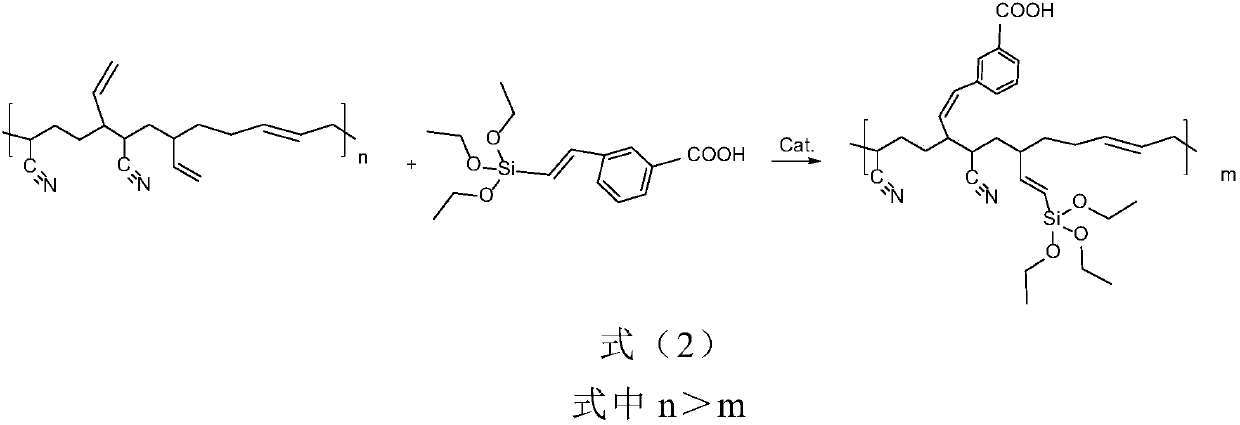

[0041] Dissolve 100 parts of nitrile rubber NBR3305 in chloroform solvent and prepare a 1.3% concentration solution, add 0.66 parts of olefin metathesis catalyst And 13 parts of anti-scorch rubber reinforcing agent 1-1, at 15.9 ℃ isolated from air and water, reacted for 0.53 hours, the reacted glue solution was removed by solvent to obtain a reinforcing plasticizer, and its Mn was measured to be 6800.

[0042] Mix 100 parts of nitrile rubber NBR3305 on an open mill...

Embodiment 2

[0047] Mix anti-scorch agent 3-vinylphthalic acid and reinforcing agent vinyldiethoxymethylsilane at a molar ratio of 1.0:0.1, prepare a solution with 1% mass concentration with hexane solvent, add to the solution Olefin metathesis catalysts accounting for 0.01% of the total amount of anti-scorch agents and reinforcing agents After isolating air and water and reacting at room temperature for 0.5 h, the solvent was removed by a vacuum desolventizer to obtain anti-scorch rubber reinforcing agent 2-1.

[0048] Dissolve 100 parts of nitrile rubber NBR3305 in acetone solvent to prepare a 10% concentration solution, add 0.9 parts of olefin metathesis catalyst and 48 parts of anti-scorch rubber reinforcing agent 2-1, isolated from air and water at 49°C, and reacted for 4.6 hours. After the reaction, the glue solution was removed by solvent to obtain a reinforced plasticizer product, and its Mn was measured to be 3100 .

[0049] Mix 100 parts of nitrile rubber NBR3305 and 14 parts...

Embodiment 3

[0055] Mix the anti-scorch agent 3-vinylphthalic acid and the reinforcing agent vinyltrimethoxysilane at a molar ratio of 1.0:4.0, prepare a 10% mass concentration solution with hexane solvent, add anti-scorch 0.09% of the total substance amount of agent and reinforcing agent for olefin metathesis catalyst Isolate air and water, react at room temperature for 4.5 hours, and use a vacuum desolventizer to remove the solvent to obtain anti-scorch rubber reinforcing agent 3-1.

[0056] Dissolve 100 parts of nitrile rubber NBR2907 base rubber in chlorobenzene solvent to prepare a 3.5% concentration solution, add 0.53 parts of olefin metathesis catalyst and 25.6 parts of anti-scorch rubber reinforcing agent 3-1, and reacted for 2.5 hours at 25°C without air and water. After the reaction, the glue solution was removed by solvent to obtain a reinforcing plasticizer.

[0057] Mix 100 parts of nitrile rubber NBR2907 and 30 parts of the prepared reinforcing plasticizer on an internal m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com