Doubling equipment

A technology of equipment and spools, which is applied in the field of production automation, can solve problems such as limiting the use range of braided cladding, achieve far-reaching use prospects and economic prospects, simple structure, and improve production and applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

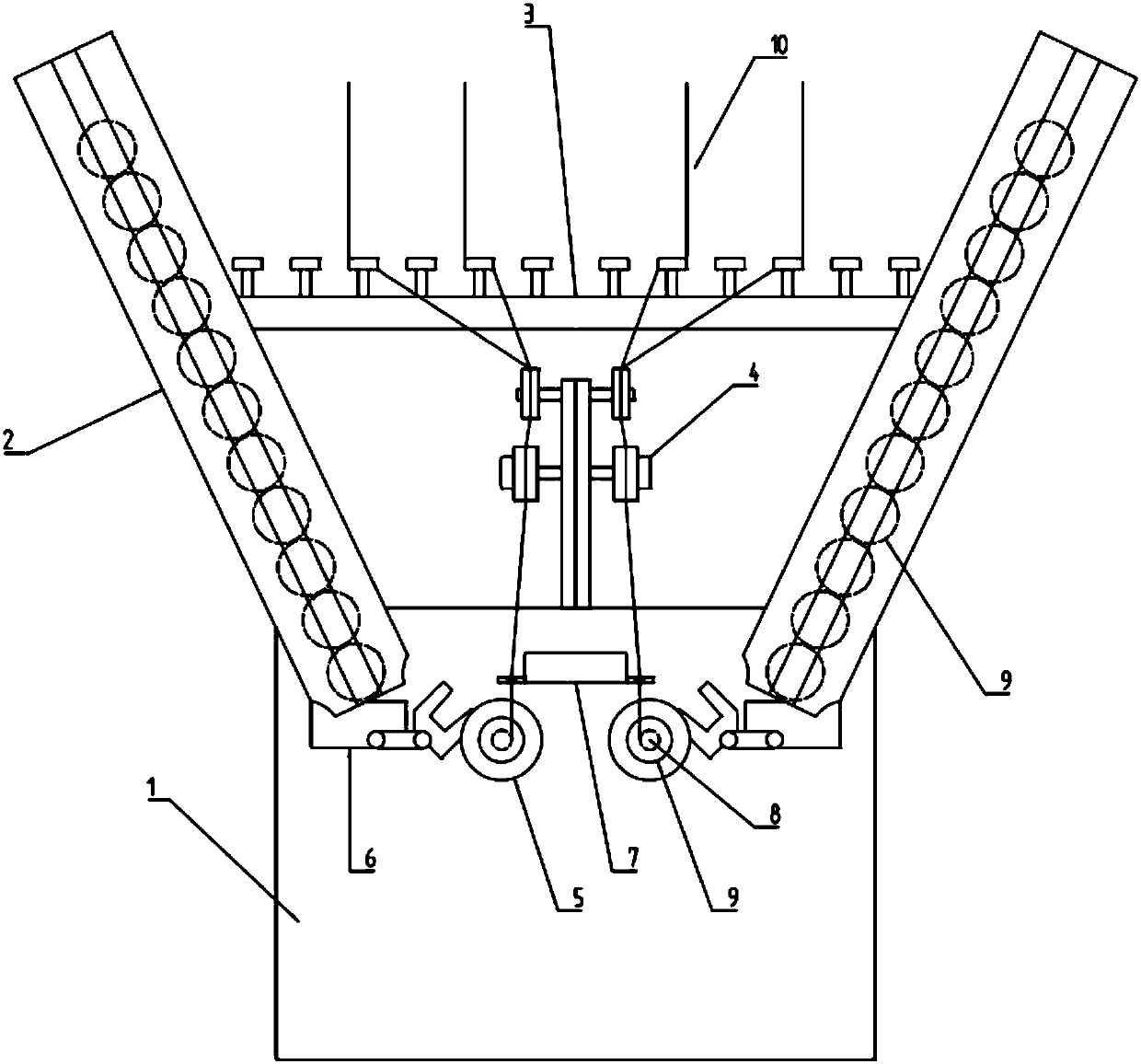

[0015] Such as figure 1 Shown is an embodiment of paralleling equipment according to the present invention.

[0016] Paralleling equipment, including machine 1, bobbin supply rack 2, doubling frame 3, wire pulley 4, bobbin rotor 5, bobbin holder 6, and winding guide 7, where the front of machine 1 is set near the two ends respectively There is a bobbin supply frame 2, which accommodates bobbins 9 to be wound, and two symmetrical bobbin rotors 5 are arranged in the middle of the front of the machine 1, and the bobbins between the bobbin supply frame 2 and the bobbin rotors 5 are arranged. The clamper 6 clamps the bobbin 9 to be wound on the bobbin rotor 5 in a movable manner, so that the paralleled yarn is wound onto the bobbin 9, and the yarn passes through and Wire frame 3, guide wheel 4 and winding guide 7, wherein yarn realizes doubling at guide wheel 4 places.

[0017] When in use, the spool supply frame 2 utilizes gravity to place the spools 9 to be wound on the spool r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com