Copying welding device free of blind area and copying welding method free of blind area

A welding device and a welding method technology are applied in the profiling non-blind zone welding device and the welding field thereof, which can solve the problems of complicated profiling welding, high functional cost, and inability to perform welding, and achieve low functional cost, strong aesthetics, Consistent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

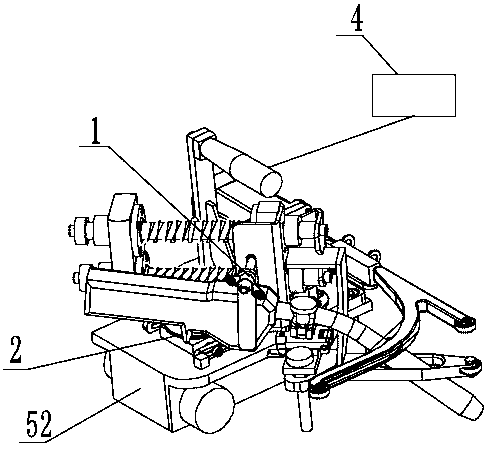

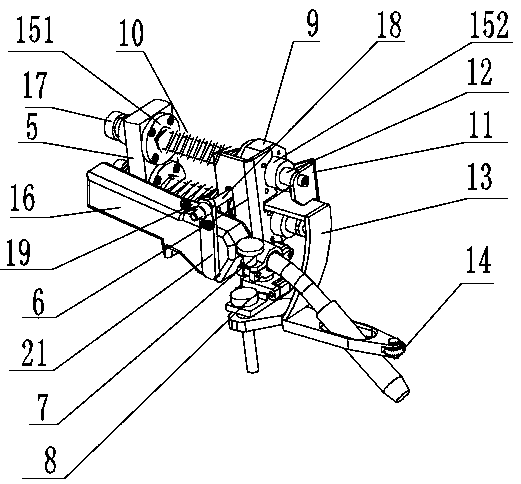

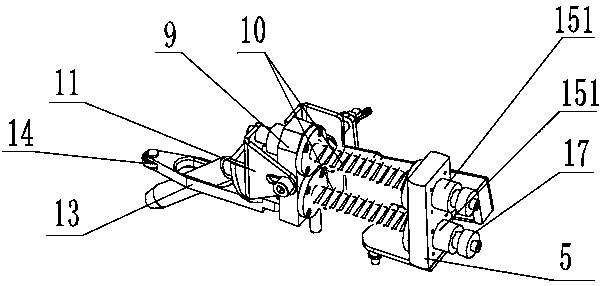

[0059] Example 1 Profiling non-blind zone welding device

[0060] Such as Figure 1-14 As shown, the present invention provides a profiling non-blind spot welding device. The profiling non-blind spot welding device includes a welding gun profiling adjusting frame 1, a driving and transmission system 2, a base 52, and a control device 4.

[0061] The welding gun profiling adjusting frame 1 includes a rotating seat 5, an auxiliary welding torch clamp 6, a welding torch clamp 7, an adjusting seat 8, a fixing seat 9, a spring 10, a spring adjuster 11, a polished rod 12, a profiling wheel frame 13, and a profiling wheel 14. The first linear bearing 151, the second linear bearing 152, the welding gun 16, the gland 17, the bolt 18, and the wing nut 19.

[0062] The rotating base 5 is located at one end of the polished rod 12, and a light hole is opened on the rotating base 5, and the first linear bearing 151 is embedded in the light hole. The number of light holes is preferably two, and wh...

Embodiment 2

[0095] Example 2 Method of profiling welding without blind zone

[0096] Such as Figure 15-18 As shown, the present invention also provides a profiling method for welding without blind spots, which includes the following steps: a welding gun adjustment step, a welding gun straight-line welding step, and a base operating step;

[0097] among them:

[0098] Welding gun adjustment steps; put the profiling non-blind spot welding device on the workpiece to be welded, adjust the welding torch 16 to the side away from the side wheel 38, and to the limit stroke, so that the front wheel 29 leans against the front side of the workpiece 54, and the profiling wheel 14 Lean against the corner of the weld formed by the side 55 of the workpiece and the front 54 of the workpiece; at the same time, the torch linear welding step and the base operating step are started.

[0099] The welding torch is in a straight line welding step; the motor 36 is activated, and the coupling 35 and the worm 33 rotate t...

Embodiment 3

[0104] Example 3 Method for profiling welding without blind zone

[0105] Such as Figure 19-22 As shown, the present invention also provides a profiling welding method without blind spots. The difference from Embodiment 2 is that the welding method includes the following steps: a welding gun adjustment step, a welding gun arc welding step, and a base operation step;

[0106] among them:

[0107] Welding gun adjustment steps; put the profiling non-blind spot welding device on the workpiece to be welded, adjust the welding torch 16 to the side away from the side wheel 38, and to the limit stroke, so that the front wheel 29 leans against the front side of the workpiece 54, and the profile wheel 14 Lean on the corner of the weld formed by the side 55 of the workpiece and the front 54 of the workpiece; at the same time, the base running step and the arc welding step of the torch.

[0108] The operation steps of the base; the deceleration motor 49 of the base 52 starts, the deceleration m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com