Hardware stamping die

A stamping die and hardware technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of poor heat dissipation of guide posts, generation of a lot of debris, poor shock absorption of molds, etc., to reduce debris and improve heat dissipation. , Good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

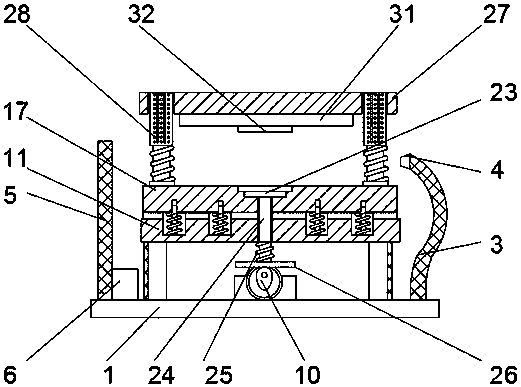

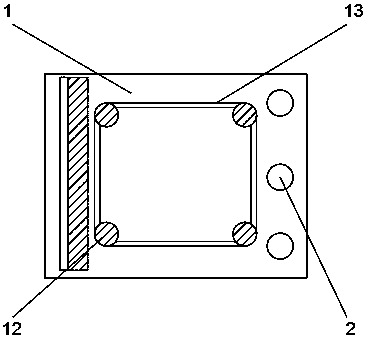

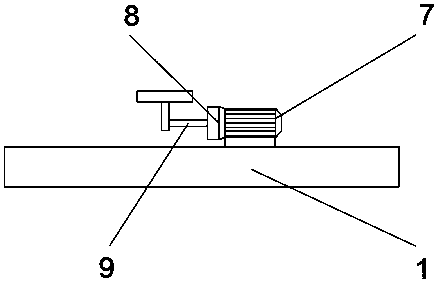

[0022] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a metal stamping die, including a base 1, a through hole 2, a metal hose 3, a nozzle 4, a chip baffle 5, an electromagnet 6, a motor 7, a reducer 8, a transmission Shaft 9, cam 10, damping plate 11, support rod 12, baffle plate 13, groove 14, positioning column 15, damping spring 16, lower template 17, positioning hole 18, buffer pad 19, push rod hole 20, stamping Groove 21, push plate groove 22, push plate 23, push rod 24, spring 25, push plate 26, upper template 27, guide post 28, sleeve 29, cooling groove 30, backing plate 31 and punch 32, base 1. A through hole 2 is evenly opened on one side of the top surface. A metal hose 3 is arranged inside the through hole 2. A nozzle 4 is installed on one end of the metal hose 3. A chip baffle 5 is installed on the other side of the top surface of the base 1. The chip baffle 5. An electromagnet 6 is installed on the side of the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com