Assembly line type food cooking device

An assembly line, food technology, applied in the field of food processing, can solve the problems of uneven quality of finished products, large steam loss, uneven cooking, etc., and achieve the effects of low cost, energy saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

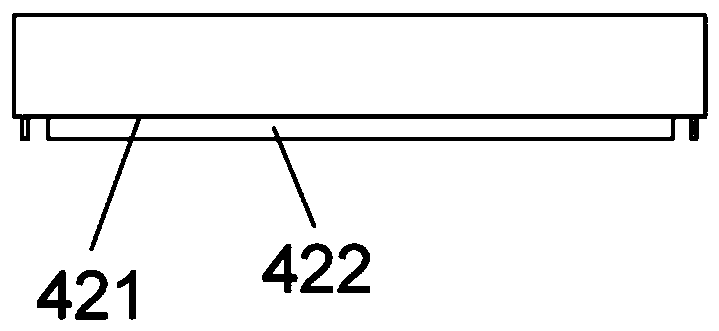

[0036] A device for steaming eels, including a frame 1, a closed-loop conveyor belt 2 arranged on the frame and conveyed around the frame, a cooking channel structure sleeved on the frame, sleeved on the frame and located in the cooking Passage exit and entrance position and the exhaust hood 5 that joins with cooking passage, described frame comprises two parallel rail frame bars that are positioned at the top, and described conveyer belt is arranged between described rail frame bars and along rail frame bar Moving forward, the cooking passage includes a cooking seat 41 fixed on the frame and covering the rail frame bar from bottom to top, and a detachable cover is arranged on the cooking seat and cooperates with the cooking seat. Cover the steaming cover 42 of the rail frame bar, and the frame is also provided with a cover structure for light and quick opening of the steaming cover, and the steaming seat is connected with an air supply pipe for sending steam into the cooking s...

Embodiment 2

[0039] The difference from the above embodiment is that the cooking seat includes a base part and a side seat part, connecting strips are connected between the two ends of the seat parts on both sides of the base part, and a water seal seat groove is provided on the inner side of the top of the side seat part , the connecting bar is also opened with a water seal seat groove communicating with the water seal seat groove on the side seat part, and the periphery of the steaming cover is erected in the water seal seat groove.

Embodiment 3

[0041] The difference from the above embodiment is that the cooking seat includes a base part and a side seat part, a water seal seat groove is provided on the inner side of the top of the side seat part, and both sides of the steaming lid are erected in the water seal seat groove.

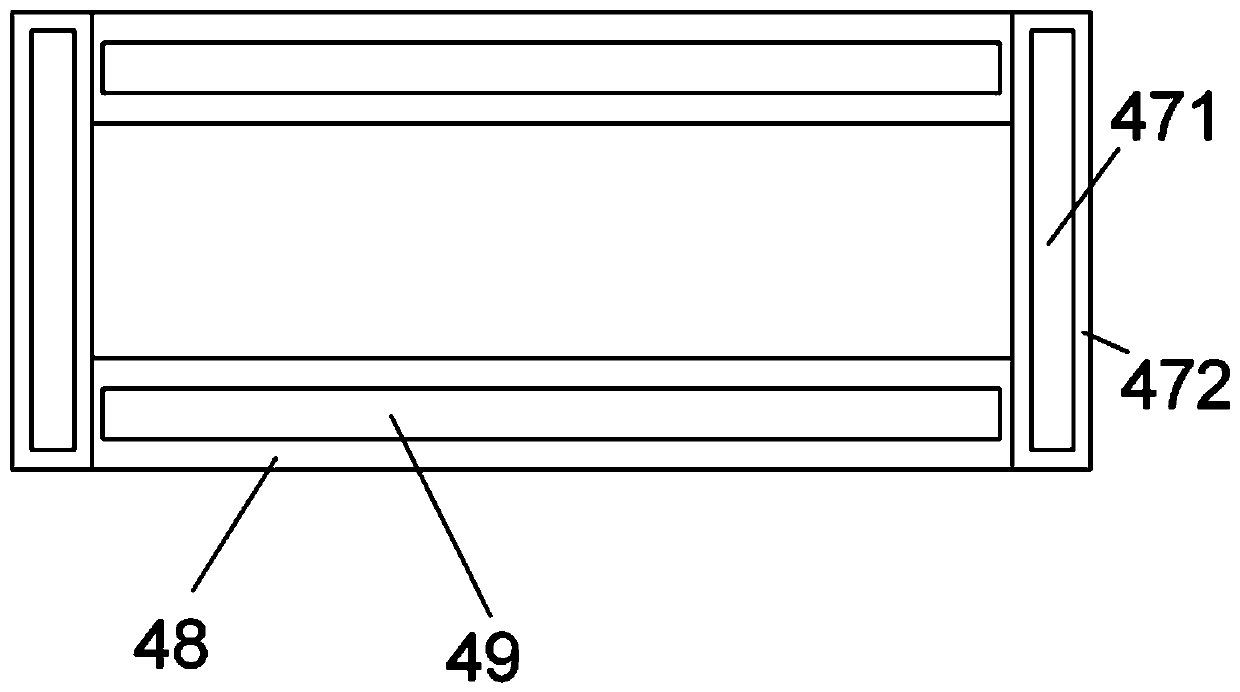

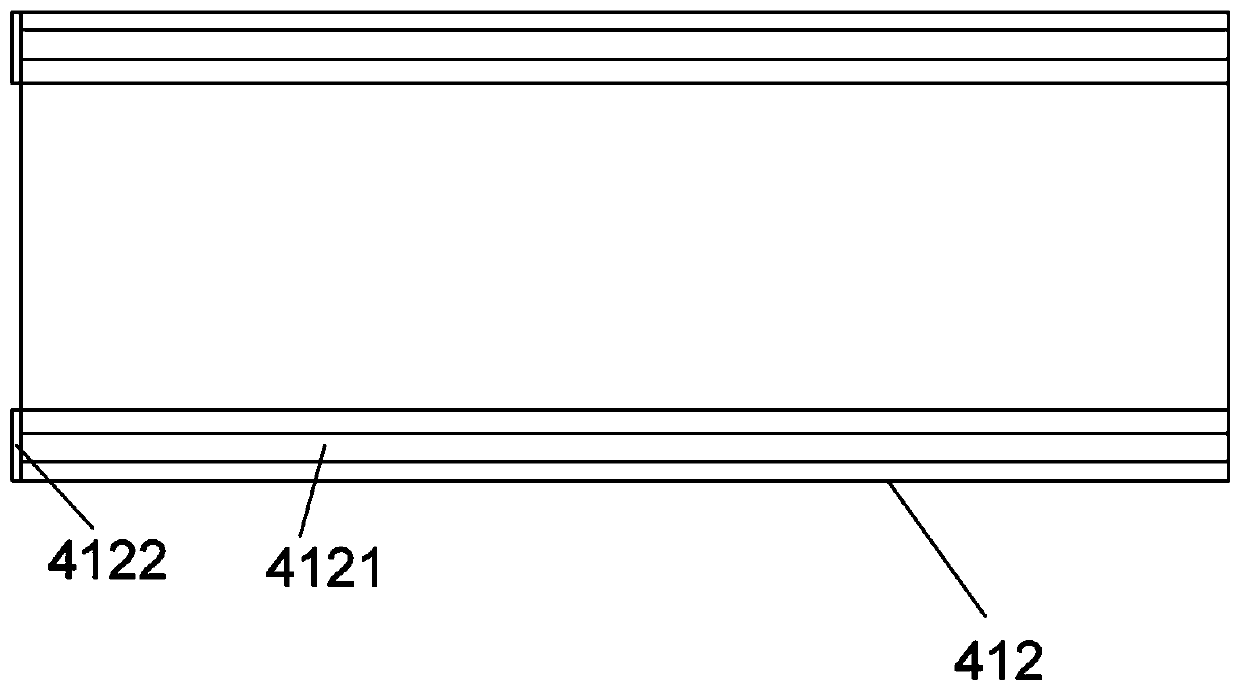

[0042] The rail frame bar includes a horizontal part located in the middle section and inclined slope parts located at both ends of the horizontal part, and the slope part gradually slopes downward from the end connecting the horizontal part to the other end, and the cooking seat is divided into corresponding middle sections The horizontal cooking part 411 and the heat preservation part 412 inclined at both ends, the steaming cover is set on the cooking part, the heat preservation part is provided with a heat preservation cover 47 on the upper cover, and the front end of the telescopic plate leans against the On the heat preservation cover, the panels on both sides are located on the outside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com