Tail gas circulating treatment system of ship denitrating system based on SCR

A technology of exhaust gas circulation and SCR reactor, applied in exhaust gas treatment, gas treatment, exhaust device and other directions, can solve the problems affecting the denitration rate of exhaust gas, atmospheric noise pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

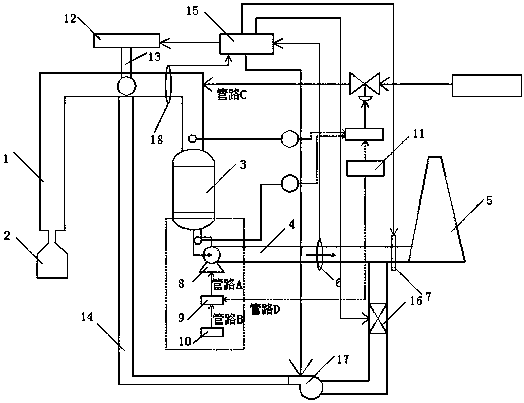

[0027] This embodiment is based on the tail gas circulation treatment system of the ship denitrification system of SCR, such as figure 1 As shown, including power release device and exhaust gas reprocessing device.

[0028] The power release device includes a flue gas denitration pipeline 1, one end of the flue gas denitration pipeline 1 is connected to the exhaust end of the diesel engine 2, the other end of the flue gas denitration pipeline 1 is connected to the intake end of the SCR reactor 3, and The exhaust end of the SCR reactor 3 communicates with the exhaust chimney 5 through the main flue 4, and the NO x Concentration sensor 6 and chimney shield body 7; Also comprise a suction device that SCR reactor 3 exhaust ends are arranged, and suction device includes suction pump 8, suction pump start-stop controller 9, suction pump power detection device 10 and diesel engine load detection device 11.

[0029] The air extraction pump 8 is connected and arranged between the exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com