Tunnel construction self-moving type waterproof plate automatically laying device

A technology for tunnel construction and automatic laying, which is applied to tunnels, tunnel linings, mining equipment, etc., and can solve the problems of high labor intensity, heavy work, and diffuse oil smoke for construction personnel, reduce mechanical cooperation and construction personnel, ensure project quality, and reduce Effects of Air Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

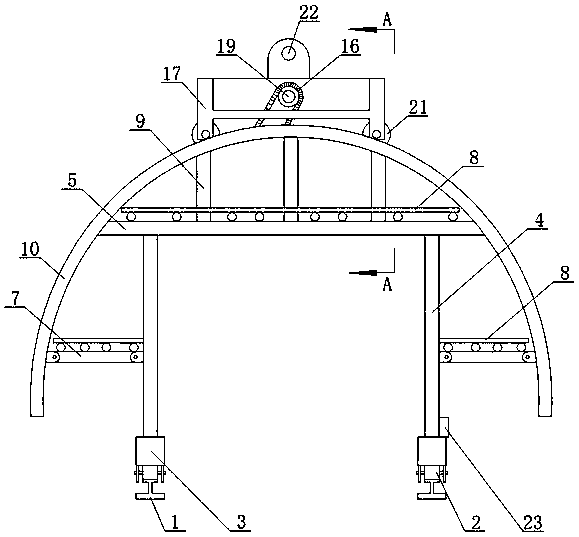

[0012] Two rails 1 are longitudinally arranged on both sides of the tunnel floor, and the traveling wheels 2 are respectively fixed at the ends of the two bottom beams 3 and placed on the rails 1. Four columns 4 are respectively fixed on the upper part of each bottom beam 3 and passed through the upper end of the horizontal Beams 5 are connected to each other to form four gantry frames, three supporting columns 9 are fixed on the upper part of the gantry frames, and the gantry frames are connected to each other through connecting beams 6. , the fixed lead screw 7 is respectively connected between the column 4 and the ring track 10, the guide rail chain 11 is laid on the inner side of the ring track 10, the fixed shaft 20 is fixed on the upper part of the double-layer sleeve 14 and the balance wheel 21 is respectively set at its two ends, The balance wheels 21 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com