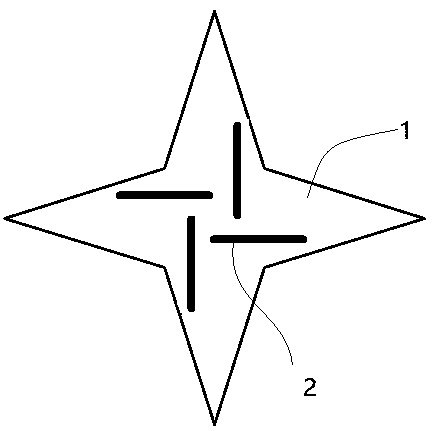

Four-pointed start-shaped fiber

A fiber and four-corner technology, applied in the field of four-pointed star-shaped fibers, can solve the problems of stuffy feeling and poor hygroscopicity when wearing, and achieve the effects of excellent anti-light transmission, good compatibility, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: a kind of four-pointed star-shaped fiber, described fiber comprises two kinds of components; Said two kinds of components are respectively polyethylene terephthalate and polyethylene terephthalate containing the mass percent that is 20-50% titanium dioxide Ethylene diformate; there are four strip-shaped first parts 2 inside the fiber, and the part other than the first part in the fiber is the second part 1, and the first part 2 contains 20-50% by mass The polyethylene terephthalate of %titanium dioxide, the second part 1 is polyethylene terephthalate; the cross-section of the four-pointed star-shaped fiber includes four sharp corners, which are respectively left sharp corner, right sharp corner, Upper sharp corner and lower sharp corner; there is a strip-shaped first part 2 parallel to the direction extending from the upper sharp corner to the center of the fiber at the right position inside the upper sharp corner; at the left position inside the lower shar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com