Double-wall-material microencapsulated red phosphorus, preparation method thereof and flame-retardant wood-plastic composite

A wood-plastic composite material and microcapsule red phosphorus technology, which is applied in the field of flame retardant polymers, can solve problems such as flammability, and achieve the effects of small amount of flame retardant added, strong interface bonding force, and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Experimental formula: microcapsule red phosphorus 17.65g (microcapsule red phosphorus powder content is 15g), sodium hexametaphosphate 0.0075g (0.05%×15=0.0075g of microcapsule red phosphorus powder mass), water 60g (with microcapsule red phosphorus powder Phosphorus powder mass ratio=4:1), magnesium sulfate heptahydrate 4.5g (the solid mass of magnesium sulfate heptahydrate is 30% of the mass of red phosphorus in microcapsule red phosphorus powder).

[0038] Put 17.65g of microcapsule red phosphorus powder coated with melamine resin, 0.075g of sodium hexametaphosphate, and 60g of water into a four-neck flask, heat up to 50 degrees, stir and disperse; Slowly add the solution into the four-necked flask; prepare a 10% solution of sodium carbonate and add it dropwise to the four-necked flask. When the pH value reaches 8.0, stop the dropwise addition, continue stirring for 1 hour, and obtain Double-walled microencapsulated red phosphorus.

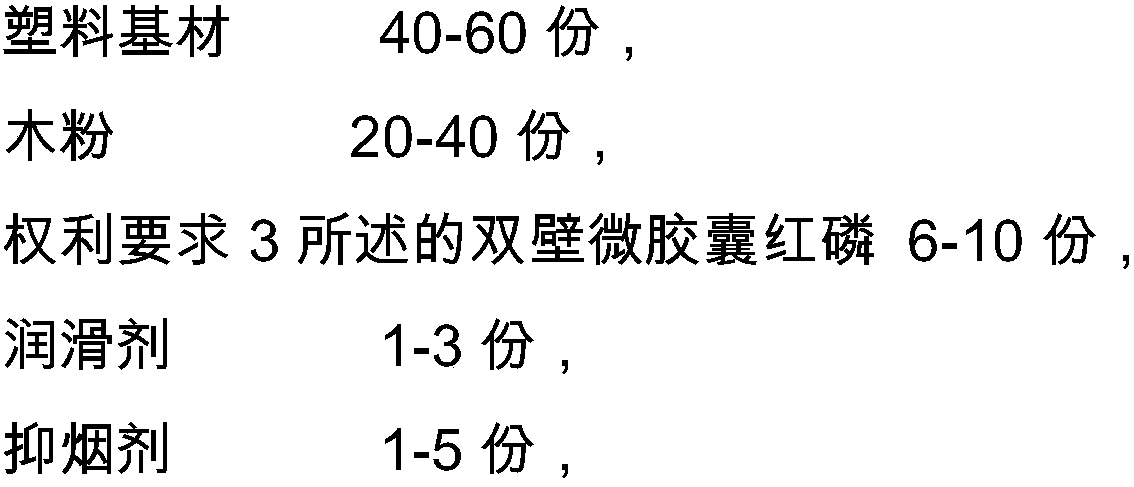

[0039] With 40 parts of polyethy...

Embodiment 2

[0041] Experimental formula: microcapsule red phosphorus 17.65g (microcapsule red phosphorus powder content is 15g), OP-100.0025g, sodium lauryl sulfate 0.0050g (the mass ratio of OP-10 and sodium lauryl sulfate is 1:3 , both total mass is 0.05% of microcapsule red phosphorus powder quality, water 60g (with microcapsule red phosphorus powder mass ratio=4:1), magnesium sulfate heptahydrate 6.8g (magnesium sulfate heptahydrate solid quality is microcapsule 45% of the mass of red phosphorus powder red phosphorus).

[0042] Put 17.65g of microcapsule red phosphorus powder coated with melamine resin, 0.025g of OP-10, 0.050g of sodium lauryl sulfate, and 60g of water into a four-necked flask, raise the temperature to 55 degrees, stir and disperse; Magnesium sulfate heptahydrate was prepared as a 10% solution, and slowly added to the four-necked flask; sodium carbonate was prepared as a 10% solution, and added dropwise to the four-necked flask, when the pH value reached 9.0, stop add...

Embodiment 3

[0045]Experimental formula: microcapsule red phosphorus 17.65g (red phosphorus content is 15g), OP-10 0.0050g, sodium hexametaphosphate 0.0100g (the mass ratio of OP-10 and sodium hexametaphosphate is 1:3, the total mass of both is 0.10% of the red phosphorus mass), water 60g (with red phosphorus mass ratio=4:1), magnesium sulfate heptahydrate 9.0g (the solid mass of magnesium sulfate heptahydrate is 60% of the red phosphorus mass of the microcapsule red phosphorus powder).

[0046] Put 17.65g of microcapsule red phosphorus powder coated with melamine resin, 0.025g of OP-10, 0.050g of sodium hexametaphosphate, and 60g of water into a four-necked flask, raise the temperature to 60 degrees, stir and disperse; 9.0g of heptahydrate Magnesium sulfate was formulated into a 10% solution, and slowly added into a four-necked flask; sodium carbonate was formulated into a 10% solution, and added dropwise to a four-necked flask, and when the pH value reached 10.0, the addition was stopped,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| autoignition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com